Everything you need to know about knife sharpening machines

To keep the knife sharp enough, it will need to be sharpened periodically. Currently, there is a wide variety of sharpeners that will allow you to sharpen such a product as quickly and accurately as possible.

Views

Let's analyze what kind of knife sharpening machines exist.

Manual

These copies are perfect for home use. Among such devices, V-shaped sharpeners and roller knife sharpeners stand out. These products have a more complex structure in comparison with the simplest bar.

Most often, such devices are used to sharpen kitchen knives.

Hand saws usually consist of two main elements: handle for the stop, one or more pairs of blade discs. Moreover, the angle between the abrasive parts has already been adjusted in such a way as to immediately select the groove and fix the edge.

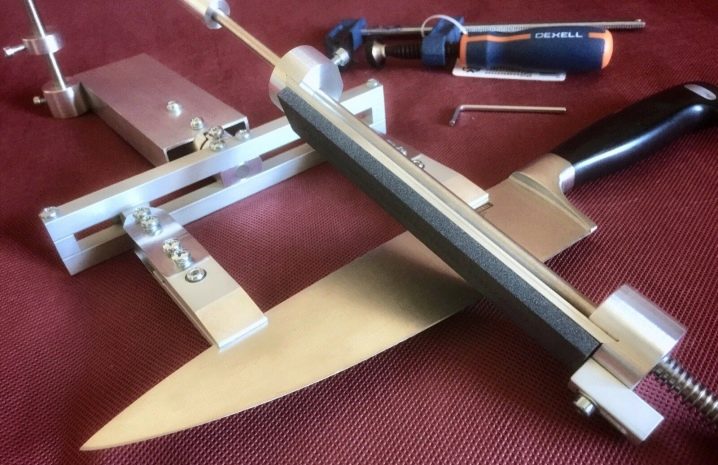

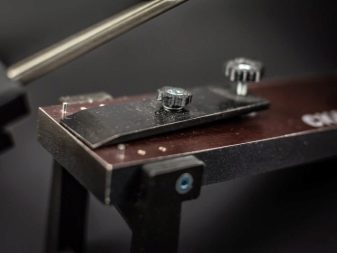

Details are fixed on a special frame, it can be steel or wooden. Most often, such products are created with an adjustable angle. There are also special clamps at one end of the frame, which are necessary to fix the processed blade.

Handmade samples are of varying degrees of difficulty. Often they include additional elements designed for thorough polishing, various retainers.

Electrical

Most often, electrical models are professional. This equipment can be easily adjusted to suit different types of blades. In this case, the knives will definitely not be damaged. Sharpening one blade together with grinding takes no more than 3 minutes.

Electric sharpeners may differ from each other depending on the power level, functionality. The most expensive models are equipped with three grooves with different discs. Such devices provide processing in three stages, they are also capable of high-quality polishing.

Popular models

Let's take a closer look at some of the most popular models of such sharpeners.

-

"Warehouse 0-9024". This domestically produced machine is manual. This equipment is installed on a table on a special curved metal frame. Simple horizontal knife holder. The blade can be sharpened at an angle of 15 to 28 degrees. Diamond bars are also included in the set with the unit. This model is suitable for sharpening knives no more than 7 millimeters thick.

Such a machine has a relatively low speed, so it is absolutely safe to use.

- GANZO Touch Pro Steel. This machine is made of stainless steel. It is characterized by simple and convenient adjustment. One set contains four bars for different sharpening levels. The design provides special small holes for stationary fixation of the knife. This device is perfect for processing scissors, as well as serial sharp products, band knives.

- RUIXIN PRO RX-008. This inexpensive Chinese-made machine is equipped with a convenient rotary mechanism. It is of the manual type. In this case, the knives are mounted in a vertical position. Processing is carried out using a special stone on the stock. The set contains small whetstones with different grain sizes. The design is relatively lightweight. The device itself is easily fixed to any horizontal tabletop.

-

VICTORINOX 7.8721.3. This Swiss hand-held model is equipped with a convenient two-stage sharpening system.In its manufacture, a ceramic abrasive is taken. This handheld sharpener allows you to sharpen different types of knives as quickly as possible.

- Zigmund & Shtain ZKS-911. This knife is electric. In the manufacture of the device, corundum of high, medium and small levels of abrasiveness is used. This machine allows you to sharpen knives with high quality in just a couple of minutes. Abrasive discs during processing rotate at a speed of 2800 rpm, at this speed, knives made of hard carbon steel and alloyed mild steel can be sharpened. In addition, the device will allow you to perform finishing and polishing. The unit has special adjustable guides, they set the correct angle of the tool during operation.

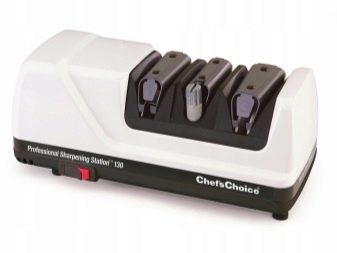

- Chef's Choice CC130W. This professional electric model is also in the top of the best. It will allow you to form a sharp, high-quality edge on almost any knife. And also the machine will allow you to perform finishing and polishing. The technique is supplied with a whole system with flexible spring-loaded guides, they provide an exact angle of the product approach to the abrasive. And also the model has a unique three-stage EdgeSelect system, which ensures the correct selection of the edge.

The sample is equipped with a built-in cleaning mechanism. It allows you to easily get rid of metal chips that are formed during operation.

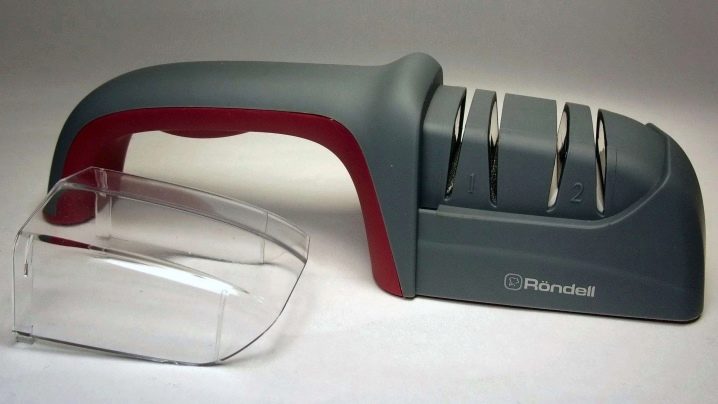

- Rondell RD-323. This mechanical type machine is used for high-quality sharpening of ceramic knives. It will allow you to process the blade as quickly as possible. The abrasive element is a ceramic stone with several different grit levels to achieve the best result.

- Hatamoto EDS-H198. This fixed angle electric specimen allows you to sharpen a variety of knives as quickly and easily as possible. This sharpener boasts a high build quality. It is suitable for processing ceramic, metal knives. The machine is equipped with durable diamond discs with different grain sizes. Metal shavings that are formed during operation are collected in a special tank.

- GANZO Touch Pro Steel. This electric sharpening machine is manufactured in China and provides a high level of sharpening. Moreover, it can be suitable for both professionals and beginners. The device is also used for processing hunting and tourist knives, as well as axes. In one set with the technique, there are four water stones with varying degrees of granularity, they are perfect for sharpening, polishing, and finishing products. Additional stones can be purchased separately if required. This sharpener can be fixed both vertically and horizontally.

The model is considered stationary. The device has special holes for bolts, they are needed for fixing equipment on the table top. The device can be folded up compactly.

- "CALIBER TE-150/300". This benchtop machine is compact in size. It is supplied with two abrasive stones, they allow you to sharpen and polish cutting products quickly and efficiently, and the machine also allows you to process drills and chisels. In the process of work, the equipment rotates at a speed of 2950 rpm. To ensure a secure and precise position of the knife, there are special stops. This model belongs to the budget category, it will be affordable for almost any buyer.

-

"VORTEX TS-200". This stationary electric sharpener is compact in size. It is perfect for home use. "VORTEX TS-200" is suitable for sharpening various knives, scissors and other cutting tools. In the production of the structure, a powerful motor (200 W) is used. The machine is able to function for a long time without overheating and failures. This machine is often used in garages and car workshops.

- FISKARS Xsharp. This mechanical specimen is supplied with a durable ceramic abrasive.It is perfect for quick processing of garden cutting tools. The model has a fairly simple sharpening mechanism; there will be no need to select the angle of the blade position. The cutting edge is simply fixed in the groove and then passed several times over the abrasive surface. The device is perfectly attached to a flat work surface due to the anti-slip insert.

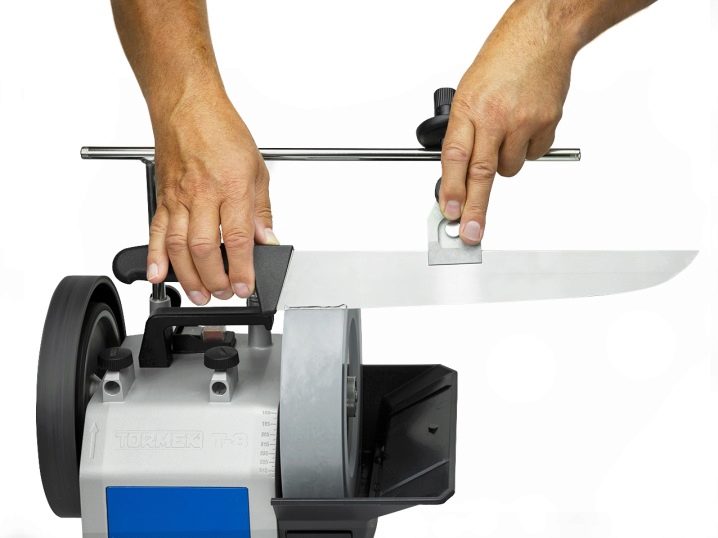

- Tormek. Such a semi-professional machine, as well as many of its copies, are considered a universal sharpening technique. It is perfect for processing flat and kitchen cutting tools, as well as knives of woodworking planers, axes, chisels. The model is supplied with electrocorundum and a special finishing leather disc that rotates at a speed of 90 revolutions per minute. In this case, the first element is placed in a container with water. The combination of low speed and constant cooling results in high quality sharpening. The sharpening angle on such equipment is adjusted using a special device, correcting for wear.

- Sititek "Mistress 31M". This knife sharpener is equipped with a strong and reliable body lock with a vacuum suction cup, this system provides the most stable position of the unit. The device is able to independently select the optimal processing angle. Metal shavings that are formed during operation are collected in a special container. In the manufacture of such equipment, metal plates with an increased level of hardness are used; they can easily cope with any type of metal.

- Nadoba Borga 723311. Such a compact sharpener is also among the best. It is equipped with a comfortable plastic handle, which provides a secure grip during operation. The handle has rubberized inserts that prevent slipping and ensure safe handling. The model is equipped with two sharpening discs of increased hardness, they can process blades made of different metals. Products are processed in two stages. First, a rough processing is performed, and then a fine finishing is carried out to maximum sharpness.

The sharpener can be easily washed in the dishwasher if necessary.

- KitchenIQ 50387. This model of the electric type is used for sharpening, lapping and polishing cutting tools, including knives from a meat grinder. It is equipped with fine to medium grit diamond grinding discs. The sample is equipped with an anti-slip base.

- Sakura SA-6604R. Such a powerful apparatus (120 W) is used for high-quality and prompt sharpening and polishing. It is supplied with two sanding discs for coarse and fine sanding. The machining angle is easily adjusted automatically. This device is perfect for sharpening steel products; it cannot be used for ceramics.

- Samura SEC-2000. This device belongs to the budget category. It is equipped with a replaceable sharpening unit. The model allows for coarse and fine sharpening. The design is available with durable diamond-coated discs. Samura SEC-2000 is perfect for sharpening ceramics and various metal alloys. The base of such a device is anti-slip. The unit has a low noise effect during operation.

- Lumme LU-1804. This model also applies to the budget group. She will do an excellent job of sharpening scissors and knives. The device is lightweight, it is only 400 grams. The device is powered by four batteries, so it can be used without being connected to the mains.

Nuances of elections

When choosing a suitable grinder, you should pay attention to some important nuances. If you are looking for an electric model, the power level must be considered. For home use, the simplest samples with low power are suitable.

The speed of rotation is also important.If you need to sharpen metal parts of increased hardness, then it is better to select models at a high speed.

Pay attention to the dimensions. For home use, it is better to select the most compact copies so that they do not take up too much space.

The functionality of the equipment is important. Professionals often select models for themselves that are capable of sharpening products, as well as polishing and sharpening. In addition, for permanent use, it is better to select models with a cleaning system and a water cooling system.

How to sharpen knives correctly?

Now we will analyze in detail how to properly sharpen cutting tools with such equipment. It is important to fix the product correctly in the machine holder. Otherwise, the sharpening will be skewed.

Holding the blade firmly, tighten the special clamping screws until they stop. To control the sharpening angle, you should use a marker, with it you mark the chamfer of the product to be machined.

When processing wooden products, you cannot do without an electric jointer. Before starting work, you need to set up the equipment. After all, many models can work in different modes.

If you have a stationary device, then proceed to adjust the table. Most often, the units are equipped with special fasteners that allow you to securely fix the equipment on flat surfaces.

During operation, the holder moves in the direction from right to left, while all movements are performed relative to the grinding stone. The cutting tool must not be allowed to protrude over the edge. It is recommended to immediately fix the holder 10-12 mm from the edge of the working area.

If sharpening is in progress, it is best to supply water cooling to avoid overheating and malfunction. During processing, make sure that the abrasive surface remains clean, as it can get greasy rather quickly.

To clean the abrasive, a special block is used. Cleaning should be done regularly. After sharpening, fine-tuning is most often performed. For this, a special paste is taken. Further polishing is done. After it, burrs and other defects should not remain on the cutting tool.

The comment was sent successfully.