What are the packaging machines and how to choose them?

To facilitate production, special machines, mechanisms and devices are created, which, due to their speed and convenience, improve the work process. Packaging machines are a technique that facilitates wrapping an item in packaging and allows everything to be brought to automaticity without human intervention.

general description

The packaging of items or food is an important and fundamental step in the production process. It is necessary in order to ensure the safety of all materials, and it is also responsible for the expiration date.

Packing items since ancient times. When they began to develop new lands, the navigators transported all the treasures in boxes, which were filled with straw for amortization. But industrialization does not stand still. People understood that it was impractical to transport some things in this way, so they began to come up with new packaging.

The first registered packaging machine was made in France in 1798. And then the mechanism was slightly modernized, and the packaging began to be produced in rolls. This happened in England in 1807.

Since that time, the machine tool market has undergone a number of changes and acquired the form that we are now seeing. Everything was aimed at the result and the safety of the product in the package.

The machines are required for the following operations:

- packing;

- package formation;

- package;

- application of labels and dates.

Each product has its own type of machine. It is customary to subdivide machines according to the type of packed products:

- free flowing;

- liquid;

- solid;

- powdery;

- viscous;

- pasty;

- single products (a piece of fish, meat).

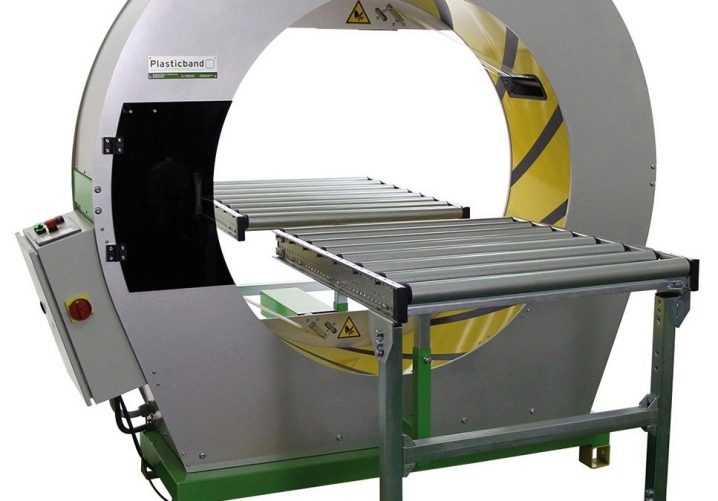

Let's consider the principle of operation of a simple packaging machine (most often used when packing boxes, large products). Film or other material is loaded into the machine, onto the main cassette and the secondary cassette (they are also called carriages). They move along a trajectory set through a computer at high speed and pack a box in 1-2 minutes, depending on the number of layers of tape.

Species overview

Packaging machines are used in many industries, because packaging has become so well established that for some people it has become the norm in everyday life and a guarantee of quality. There are a large number of wrapping machines. They are subdivided by orientation, by the materials that are loaded there, and divided by classification and size. There are special machines that pack furniture, there is a filling and packaging machine for bulk products. Packaging can be vacuum or shrink-wrapped.

By types of equipment, it is customary to divide into cyclic and continuous supply.

- Cyclic feed. The principle of operation is that the mechanism works according to a clearly defined schedule, that is, according to a timer. The product enters the compartment, carriages with tape work around it and wrap the product in the allotted time, set manually. By the end of the cycle, the required units of the product are packed, and the machine proceeds to the next packaging. The work process can be conveyor or manual (the product is loaded by a person).

- Continuous feeding. In this case, a conveyor is meant, and the packaging of the product takes place in a continuous mode for a certain (long) time.

Machines are also divided according to the number of operations that are incorporated into them at the plant. But only two main ones stand out:

- complex operations include several subspecies: packaging, packaging and packing;

- highly specialized contain only one of the above subspecies.

And also machines are divided according to the mode of action. They can be vertical (winding occurs vertically), horizontal and vertical-horizontal (combined method).

Each product category has its own packaging machines. For example, in order to carry out long-term transportation or preserve products, furniture packing machines or a pallet with stretch film are most often used. The film has increased strength and excellent adhesion to the previous layer.

Consider other options for devices.

- Tunnel type heat shrink units. Packages are sealed from all sides. They are intended both for the food industry and for the construction industry, but they are also found in other areas (for example, when packing napkins).

- Clippers. Semi-automatic machine. It is necessary for hermetic packaging of bags with plastic clips. Most commonly used in bakeries for packaging bread. The advantage of this machine is that it is equipped with a printer that prints the date of packaging on clips.

- Bag sewing machines used for sewing bags with bulk products (flour, pasta). They are presented in the form of a mini-machine or a pistol, which is easy to hold in your hands. If desired, it can be installed in the machine cage.

- Vacuum machines. Their peculiarity lies in the fact that the bags are sealed so that one edge remains open. Suitable for catering industries. They are subdivided into two-chamber machines (perform a large volume) and conveyors (the advantage lies in speed).

Popular manufacturers

There are a large number of machine tool manufacturers on the market. You can find Italian, Russian, Chinese and American cars. They are the same in functionality, but differ in power, assembly and materials. Let's take a look at some of them.

- WoodTec Ecopack 300 machine using stretch film. Designed for oversized products. The film is used with a thickness of 17-30 microns. The winding cycle is regulated. The working surface is equipped with metal rollers and one-sided positioning along the guides.

- NELEO 90 is a semiautomatic stretch film machine. Manufactured in Spain. It differs from the previous one in lower performance.

- Shrink machine "Element", Russia. It can pack various products in plastic wrap. For each item, characteristics and materials are selected manually and entered into a computer. In order for the device to work fruitfully, there is a special film with a thickness of 60-80 microns for it.

- Machine "TM-2A" with heat shrinkage. It differs in that it packs items individually or a group of different packages into one.

Expendable materials

Most often, the following materials are loaded into the machines:

- paper or kraft paper (high density);

- vacuum bags;

- film;

- polymer film;

- corrugated board or beer board;

- stretch film;

- heat shrinkable sheath;

- metal containers on a paper basis.

Selection Tips

Before purchasing a particular model of the machine, you need to understand how often the device will be used. Performance and the search for the required power depend on this. It is important to understand what kind of products the device is purchased for. It can be food products, furniture (small or oversized), building materials.

It is worth considering the dimensions of the machine. Typically, large machine tools require a large floor space, as well as soundproofing or a remote utility room.

The comment was sent successfully.