Lathes for metal

A lathe is not only an attribute of some manufacturer that produces, for example, bearing kits, sprockets, gears, discs, connecting rods and other elements. Home lathes are an increasingly frequent occurrence for a summer cottage and garage master.

Types and characteristics

A metal lathe has some differences from a similar device that performs woodwork. An industrial or household, school or garage, narrow-profile or more universal unit has its own accuracy class and has a certain weight. The description of the product allows you to highlight an exhaustive classification by the type and purpose of the device.

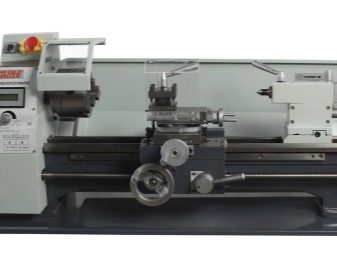

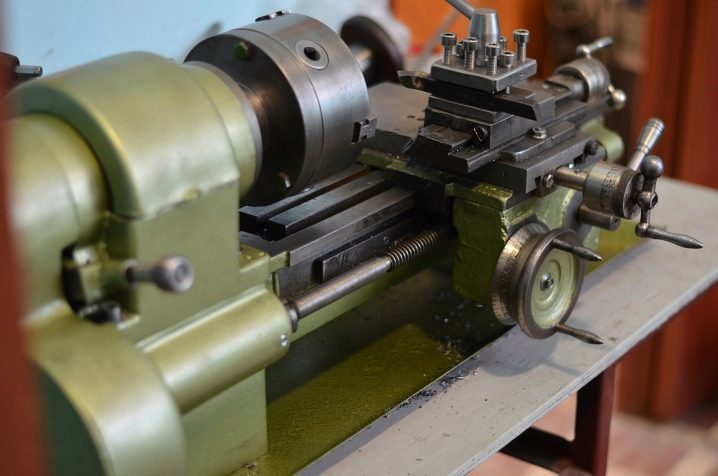

Tabletop

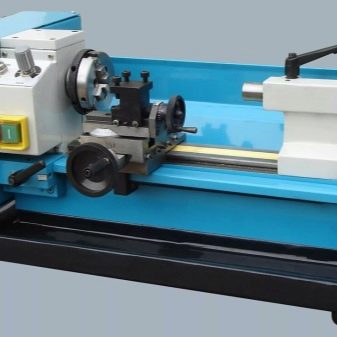

By purchasing the right equipment, the master will significantly save on the production that he wished to open. Home lathes, which are mostly bench-top, weigh up to 20 kg. You can purchase a machine of greater weight and dimensions if this option is compatible with a workbench (about 1x2 m or even a more impressive table in terms of area). The power consumption of bench-top machines starts at 400 watts.

The tasks of the master are not so extensive, but he will successfully cope with his list of works on such a machine. An example is the use of such units by small car service shops. There are times when, say, it is necessary to grind out some parts for the carburetor to replace the failed components that have already burned out in the mode of intensive and harsh operation. Having purchased steel of suitable grades in blanks, the master will start turning such parts.

With the help of a desktop home machine, you can grind tapered and cylindrical parts, correct and trim their ends, grind an already machined component, cut a neat hole in it using the reaming method, drill out an existing hole even more, cut an external or internal thread.

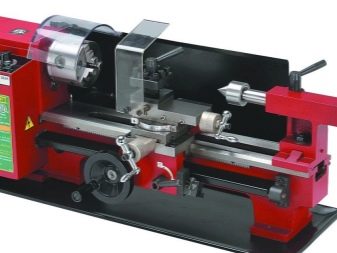

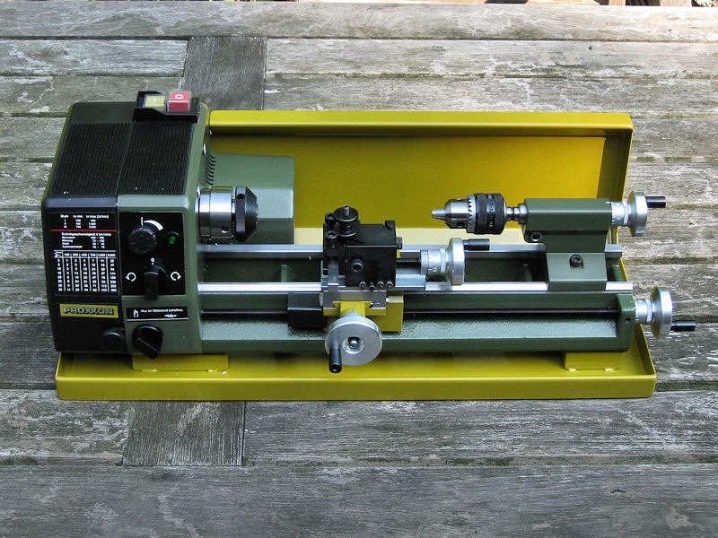

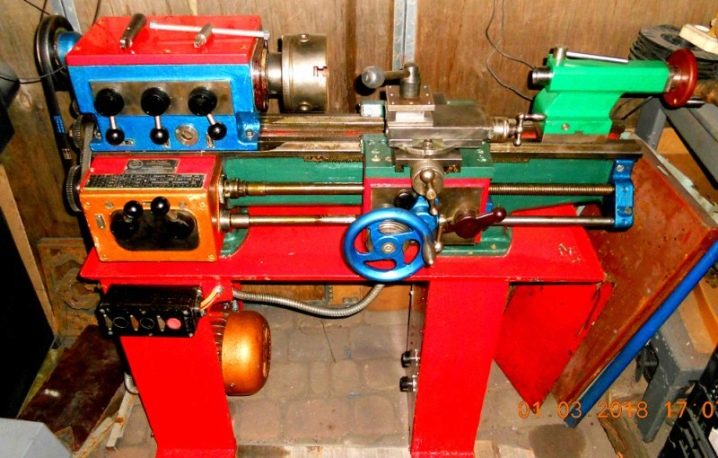

Semi-professional

If the experience you already gained seemed insufficient for successful development, and you would like to advance further as a professional turner, then you may be interested in models of a higher level than an ordinary household lathe. The power consumed by such devices will exceed a kilowatt. The functionalities of drilling and milling household machines are combined in such devices. They are successfully used in the case of small production capacity and for small-scale copying of the same type of parts of one or more types.

You will not be able to produce large parts and / or large series. However, the final product will be of no less quality: the task of the machine is to facilitate the work of the master. The area of application of such machines is small workshops, as well as garage repair of cars.

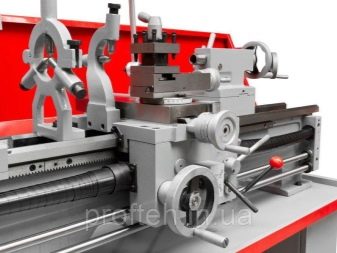

Professional

One of the latest steps in development is numerical control (CNC) machine tools. Having mastered the skills of working on machines without this unit, a professional worker and an actively developing foreman proceeds to a larger-scale production of parts. Performance indicators are the highest compared to conventional and semi-professional models, but the main disadvantage of the machines is great massiveness. In this regard, their use is significantly limited by the conditions of factories and plants.

Based on the above-mentioned advantages and disadvantages, a professional machine for home use will still not be fully such. However, it is possible to produce small-sized components on such a machine using the support of the CNC module. At the same time, efficiency and quality will reach a new level.

A universal machine is the shortest way to high-volume and high-quality production of components of any complexity. He supplanted narrow-profile models, allowing many workshops and factories to re-equip and convert to a wider-format production, producing consumer goods and highly specialized consumption in significant quantities, while their production became cheaper and faster.

Appointment

For a house and a garage, a workshop is organized, as a rule, within a small range - about 10-15 m2. It is not a problem to grind a ball on the machine, to make souvenirs of any complexity, to use the refinement of blanks that have passed preliminary and main turning, but in this case, a more subtle finishing of the blanks to the planned look, the image is still required.

Household machines, in addition to direct grinding, also need the timely removal of excess material cleaned off from the workpieces being processed. This is achieved with the help of a vacuum technical vacuum cleaner, which is a rotary hood - a kind of cyclone or siphon mechanism, and the latter is not afraid of clogging with waste. This will ensure the evenness and accuracy of the work done: if the cutters walked through the places of the freshly cleaned shavings and metal dust, then part of the kinetic energy of the mechanisms would be extinguished, as a result, the quality of work would become less orderly, more chaotic.

Home machines are somewhat lighter than garage ones... In order not to clog the workplace on the table in the working room, including the one converted into a living room, more stringent requirements are imposed on protection from chips flying in all directions, timely and complete collection of metal dust. But machines, mainly working with steel, are still used in a utility room or garage.

If we judge about the specific purpose of the machine, then there are models exclusively for processing non-ferrous metal and for working with steel blanks. Machines designed for the first will not be able to work with the second, while backward compatibility in this case is possible (and acceptable).

The purpose of machines for non-ferrous metal and steel is justified not only by the power of the engine and other mechanisms, but also by working with cutters made of high-speed steel and having diamond spraying, victorious edges, etc. machine tool for school. It easily allows you to grind any simple parts, roll and grind them no worse than a more highly professional model.

Device and principle of operation

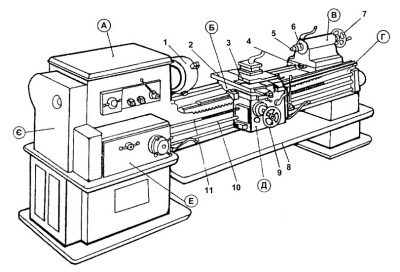

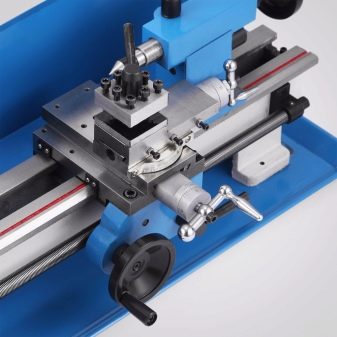

The first thing any machine starts with is a cutting (working) table. The equipment and accessories of the unit are determined by its classification (by type, type), performed by the structure, on which such auxiliary and main elements are fixed as the head and tailstock (elements interacting with the spindle), dividing head, stand (or movable platform), guides , the drilling / turning head itself with the cutters fixed to its chuck.

The machine is designed in such a way that its cutting milling cutter, used at the moment, and guides moving the workpiece to be processed, interacting, complement each other's action. Automatic control, on which evenness depends, the quality of the turning, as previously noted, is due to the coordination of the milling head from the side of the CNC unit.

So, all the same school machines are subdivided into table and floor machines. They include a frame made of cast iron or steel alloy, which is resistant to vibration.The headstock and tailstock, cutter holder, and support module are mounted on the frame. There is no gear shifting on school vehicles: it is implemented only on the basis of a belt drive. The main component of the device does not have a special purpose technological channel. The liquid (oil) cooling device flows through the liquid medium supply system. Otherwise, this liquid is introduced manually after a certain time or number of production cycles.

Each machine is necessarily equipped with a manual emergency braking system. Manual braking reduces the rate of rejection of parts, in the production of which the craftsman could overdo it.

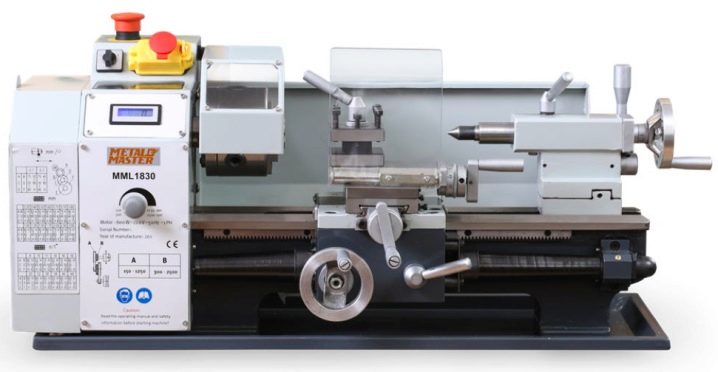

Review of the best models

Famous brands are constantly presenting new models. Machine tool activity has penetrated so deeply into all areas of amateur and professional production that it is impossible to advise a beginner to choose a specific model. The top (rating) of models is constantly changing, and yet it is worth giving an explanation for several models.

- Jet BD-7 works from a household power supply. The tabletop model works with non-ferrous metal, plastic and wood. Dimensions - 86x33x37 cm, distance between centers - 30 cm, turning diameter over the bed support - 11-18 cm. Power consumed from the network - up to 590 W. Revolving - from 100 to 3000 rpm every minute. Unit weight - 44 kg. The highly massive frame does not allow the unit to vibrate, there is a smooth adjustment of the spindle speed, the possibility of reverse, the display of information about the engine speed on a digital display.

- Garage machine "TV-4" was carried out for schools as a special educational modification. It is quite full-featured, as well as compact, which is why it is still actively used in home workshops. This device consumes 1 kW, allows turning parts up to 30 cm long, speed - up to 710 rpm. However, its weight is 280 kg. Part section (cut length) - up to 20 cm.

- "TV-6" (brother of "TV-4") drills holes, grinds ends, cuts workpieces into pieces, applies metric threads, bores cones and cylinders. Disadvantage - dusty room, you must use a respirator and goggles, headphones. This unit consumes 1100 W, grinds parts up to 35 cm long, their cut section - up to 20. Gives 700 engine revolutions every minute. Weighs three centners. The length of the workpiece grooving is at an interval of 30, not 35 cm. This model is suitable for machining wheelsets, clutch kits and other parts similar in principle of operation and structure.

- Machine tools "TV-7" has a different design of the spindle assembly (compared to the previous version). The rest of the parameters will be the same as for TV-6.

- Jet JWDP-12 716000M - a device that works with workpieces made of metals and wood. Equipped with a V-belt transmission mechanism, due to which the spindle speed is set at a specific mark. It has a table with a vise fixing device.

- Proma E-1720FVL / 400 - outdoor option. The cutting table rotates freely in all directions. The machine is equipped with a regulator for drilling depth and spindle speed. Equipped with a digital scale showing the rpm value and an illuminating lamp.

- "Enkor Corvette-441 94410" - vertical drilling machine, powered by an asynchronous motor, equipped with a tank for cooling liquid. It has a safety and reloading module and a scale for tracking the vertical movement of workpieces.

- Dewalt Dwe1622k small in size, quickly and efficiently drills metals. He works with 5 cm diameter drills.

- Proma BY-3216PC / 400 - device of premium quality and fields of application. Height - 14 dm, there is a cooling module and an automatic feed device for the workpiece. Drills holes up to 2.4 cm in diameter in cast iron and up to 2 cm in steel workpieces.

Criterias of choice

You can choose the required machine based on the specific values of the parameters of each of the models. Even mini-machines for dentistry are included in the category of such equipment.

The size of the device significantly affects not only the price, but also the power. It is irrational to create a large-sized, but insufficient in terms of power output unit. The opposite is also true: not a single manufacturer has yet created small-sized and powerful devices. Maintenance and repair costs are also reduced, depending on the size of the unit.

Together with the dimensions, the weight also grows. It makes sense to install high-tonnage machines only in rooms for which a reinforced foundation was laid. So, the largest garage products weigh 21 centners, the weight of the component fixed in the cartridge is 3 centners, and the one installed in the center is about 13 centners.

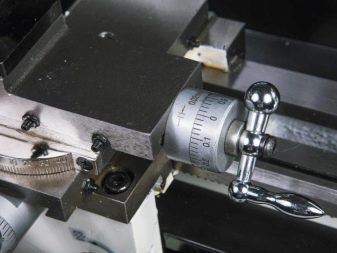

In terms of the dimensions of the workpiece, the sample passed through the spindle clamp is 4.5 cm with a hole width of 4.7 cm.The diameter of the part above the frame should be no more than 40 cm, above the support module - about 22 cm.

The dimensions between the centers are 1 m.The length of the device is up to 281.2 cm, the width is up to 116.6 cm, and the height is up to 132.4 cm. Finally, the drive power should not exceed 10 kW: a large load, as practice shows, is not not a single household (apartment) network will withstand.

However, all machines with a power of up to 1 kW are capable of operating from a gas generator that has a double or triple power reserve (2 and 3 kW, respectively), while a voltage drop greater than 22 V is excluded.

Exploitation

Observe the safety precautions before using the machine. The replacement of cutters is carried out only when the equipment is completely de-energized. Remember to lubricate the rubbing parts of the mechanisms at the intervals prescribed by the manufacturer of your device. Cutters and other consumables, as well as spare parts are stored in a special closed shelf inside the machine.

When using a multi-tool that works with several cutters at the same time or in turn, but without changing cutters, install these cutters in the sequence prescribed by the manufacturer.

Fix the machine securely by placing it on a flat surface, and remove from it all unnecessary things that interfere with work. Test the machine in idle mode before running. Do not leave the operating device, as well as its tools (cutters) unattended and restrict the access of unauthorized persons.

The comment was sent successfully.