All about JET lathes

Before buying a lathe, the consumer has questions about what criteria must be adhered to. But a lot of controversy arises about manufacturers and their assortment. One of the most famous and reliable companies is JET, whose products are used all over the world.

Peculiarities

JET lathes have a number of features that make it possible to call the equipment of this manufacturer unique and, indeed, of high quality. First of all, it is worth noting the company's approach to the production of products. For the implementation of this process, only high quality materials and raw materials are used, due to which excellent physical properties of the models are provided. This is especially important for machine tools, since design and reliability are one of the foundations of a successful product. All production is carried out in accordance with quality standards, which confirm the fact that JET products are designed for a variety of applications in a wide variety of conditions.

The next advantage of the manufacturer is range... It is extremely wide and includes many products that are classified according to different criteria. These are budget mini-machines, semi-professional and professional equipment, there are also screw-cutting units, high-precision models with CNC are also presented, where tuning and adjustment are brought to a completely new level in comparison with other analogues.

At the same time, it is worth noting the possibility of personalization before buying, when the user can independently select the package he is interested in.

The production goals are different, therefore, not all functions may be needed. And if they are not needed, then there is no need to spend money on them. Therefore, JET offers a considerable number of options for premium machine tools, and the buyer only gets what he wants. The price range of the assortment is also wide, allowing the potential consumer to choose what will meet not only his requirements in terms of characteristics and scope, but also in terms of cost.

Model overview

By wood

JET JWL-1015 is a simple machine that is an improved version of JET JWL-1014. The asynchronous motor has a power of 500 W, and the idle speed reaches 3300 rpm. This figure can be adjusted by the user without the use of tools. The bed is made of reliable cast iron, which has proven itself as an excellent material for the basis of machine tools.

The units and parts of this model have been improved compared to their predecessors and have become stiffer and more reliable. And also their design and ergonomics have changed.

The main field of application is wood processing in the form of small but long workpieces up to 900 mm. The belt transmission switches at 6 speeds, a dividing device is provided, there is a fixation of the hand-hand. The bed can be optionally extended by 533 mm to accommodate even larger workpieces. Center-to-center 370 mm, powered by 230 V power supply, swing diameter over bed 250 mm. The dimensions of the machine are 890x300x370 mm, the weight is only 35 kg.

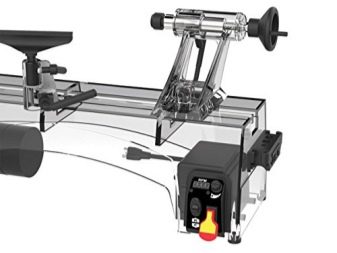

JET JWL-1221VS is a popular model that combines simplicity and reliability with the use of electronic production technologies... The bed has become wider, which, together with the increased weight, makes the structure more stable. JET decided to equip this machine with tougher and higher quality elements, among which changes were made to the spindle bearings.... Bed and stand extensions are optionally available, after which the maximum center distance will increase from the standard 450 mm to 1080 mm. Three pairs of pulleys allow you to select the powertrain range.

The adjustment of the handguard and tailstock is very simple due to the use of an eccentric fastening system. There is a dividing device that simplifies mounting and dismounting on the faceplate spindle, for which only one key is needed. The digital display allows you to quickly set the speed settings. And also a built-in reverse switch, due to which some types of work, such as grinding, are much faster and more efficient. The power consumption of the engine is 940 W, the diameter of rotation over the bed is 318 mm, the stroke of the tailstock quill is 57 cm, the dimensions of the machine are 853x280x450 mm. Dividing device for 24 positions, weight 55 kg.

This equipment is quite well known among users due to its reasonable price, reliability and an expanded range of work performed, which makes operation more flexible.

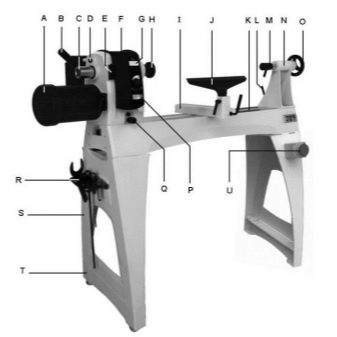

JET JWL-1840EVS is a professional product that, due to its excellent technical characteristics, well-thought-out design and built-in functions, makes it possible to perform many tasks of varying complexity.... Among the main features of this model is a rigid cast-iron bed and support legs, as well as a movable headstock with fixing angles at 30 degrees, due to which the user can process the workpiece from the side of the bed or outside of it. The electronic control system shows the current number of revolutions, there is a reverse switch.

The package includes additional spacers for legs, due to which the height of the machine above the floor level can be increased. A particularly powerful 2400 W motor with speeds up to 1200 rpm in working order allows you to machine workpieces efficiently and fairly quickly. The turning diameter has been increased to 470 mm, the extension of the bed is optionally possible. All mechanical adjustments have convenient locks; speed changes are made with minimal effort. Center-to-center is 1000 mm, tailstock quill travel 107 mm, indexing device with 36 positions.

The design provides for a considerable number of modifications that change the capabilities of the machine for processing workpieces of different sizes. There is a remote emergency shutdown button, a wide optional selection is available, allowing the user to increase the already considerable equipment toolbox. Dimensions 1854x508x1334 mm, weight 190 kg assembled.

For metal

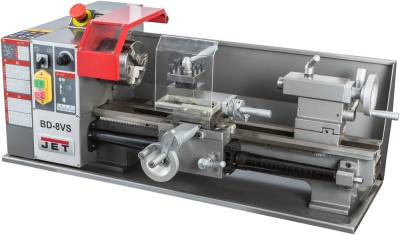

JET BD-8VS is an inexpensive desktop machine that will be a good purchase for a small workshop or metal processing workshop. The equipment is controlled by means of the front panel, on which the main indicators are indicated during the working process. Using switches and buttons, you can adjust certain positions, the design contains two automatic longitudinal feeds. Machine guides hardened and ground. The measuring devices are adjusted in such a way that the workpiece can be processed most accurately and accurately.

There is a four-position tool post that rotates and locks perpendicular to the axis of rotation of the equipment. Left and right work of the spindle, the speed setting is very smooth and is carried out in 2 ranges. During adjustment, both metric and inch threads can be selected. To ensure the cleanliness of the workplace, there is a container in which work waste is collected. Motor with a power of 600 W, processing length up to 400 mm, number of revolutions up to 2500 per minute, bore diameter 21 mm, distance between guides 100 mm. Dimensions 890x390x310 mm, weight 75 kg.

JET BD-11G - a machine that has proven itself well and has become widely used among similar products in its price range... The device is intended for small-scale production, it is possible to cut left-handed threads in metric and inch measurements. Automatic feed during turning facilitates operation, the basis of the structure is a cast-iron bed, which is hardened and ground, which makes the equipment not only stable and reliable, but also visually attractive. Taper turning is carried out by means of a tailstock with offset adjustment. The package includes a stand.

This machine has the most powerful 1100 watt motor among bench-top metal cutting machines. Six adjustable speeds, the maximum of which corresponds to 2000 rpm. The center-to-center distance is 700 mm, the diameter above the bed is 280 mm. The basic equipment includes a 3-jaw chuck and a fixed steady rest.

The bore diameter is 26 mm, the cross slide travel is 145 mm, and the guide spacing is 180 mm. And also for this machine there are several optional features, including expanded tools and some design changes. Equipment dimensions 1390x660x1285 mm, weight 180 kg.

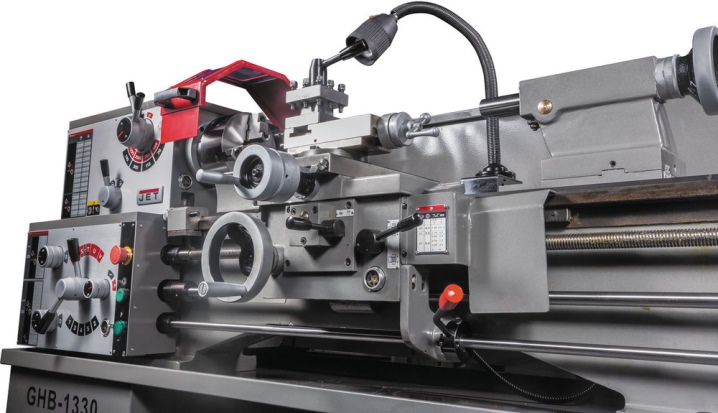

JET GHB-1330A is a professional model used in production, workshops and enterprises of various levels. One of the advantages of this machine can be called its versatility, which consists in a combination of good characteristics and technologies that make operation more efficient and convenient. There is a mechanism for automatic feeding of the longitudinal and transverse support, a jogging method of the spindle is built in, due to which it simplifies the switching of operating modes. The center-to-center distance reaches 760 mm, power supply from the power supply system 380 V, turning diameter over the bed 330 mm, spindle rotation up to 2000 rpm.

The number of longitudinal feeds reaches 60, the quill diameter is 32 mm, the distance between the guides is 187 mm, the motor power is 2000 W. This model uses a continuous cooling system, which consists in the fact that the spindle drive is immersed in an oil bath. Due to this, the operating noise level is reduced, and the resource of the mechanism also increases. Adjustment of the clearance of the guides by means of wedge strips. Dimensions 1650х762х1200 mm, weight 600 kg.

JET GHB-1330A is good because it is one of the simplest professional models, which favorably affects both the price and ease of use.... The set of possibilities is quite enough to make the processing of metal workpieces flexible and efficient.

It is also worth noting that the optional modification is also wide, allowing you to personalize the machine for production requirements.

Equipment

Before buying, it is important to consider many criteria - technical characteristics, materials of construction, the number of functions and technologies... But not all consumers pay their attention to the package, which contains various interesting accessories. As for woodworking machines, they often have handcuffs for turning tools of different widths, faceplates of certain diameters, drive centers, as well as a knockout rod. Among the more expensive models, there is a basic configuration with hinged holders for additional tools.

Premium woodworking lathes provide several stands and support legs, due to which design changes are made... For the most part, this is the set found in the JET assortment. As for the equipment for metal, everything is much more diverse here. These products can include a variety of jaw chucks, faceplates of different diameters, tool holders, pointers, bushings, wrenches and much more.

In addition to additional and replaceable parts, more expensive machines are equipped with protection of individual parts of the structure. Parts of the inventory may be provided, such as boxes, lighting lamps and everything that makes the operation more convenient.

It is important to note that the equipment of each model is individual, since it corresponds to the range of work and the number of functions that the equipment is equipped with in its category.

Review overview

Real consumers can evaluate products in the most accurate way, since the advantages and disadvantages of products become apparent only after a certain time of operation. People consider reliability and workmanship to the pluses of JET lathes. While working, users have the confidence that the equipment will not let them down. This is facilitated by the strict construction, the design of which is simple and attractive at the same time. As for the working moments, there are no complaints. The mechanisms are adjusted with high precision, the functions are in good order and will always help when processing workpieces.

And also consumers like the availability of modernization of machines and optional selection of the final configuration before purchasing. This makes it possible to first purchase a regular model and improve it over time.

A big plus is indicated by a wide assortment, where there is equipment for both premium and domestic purposes with different fields of application and a set of technologies.

The comment was sent successfully.