Types and selection of magnetic drilling machines

Magnetic drilling machine - equipment demanded in construction, industry and other spheres. The device is appreciated among specialists for its wide functionality, which provides access to the implementation of various technological tasks. It is worth considering the main types of magnetic machines and understanding how to choose the right machine.

general description

Magnetic hole drilling machine is a compact device with a magnetic base, designed to perform various operations in construction, industry and other areas. Units of this type have a lightweight design with increased reliability, the equipment is perfectly fixed on any surfaces where processing is required. The installation is used for:

- drilling;

- forming a thread inside the product;

- milling and reaming of parts.

The functionality of drilling devices allows some models to be used with other tools. For example, to form small holes, twist drills complete with crowns - special crown-type cutters - are used.

Feature of modern equipment - Designed with 26 kN magnets, providing excellent fixation of devices on any kind of surface: horizontal, vertical and inclined.

If necessary, the fixation of the device, if the surface does not allow, is provided using chain elements or vacuum devices.

Magnetic machines are often found in factories and factories where dimensional structures require the formation of a large number of holes. The main industries where the equipment is popular:

- shipbuilding;

- construction of unique structures;

- erection of dams.

Also, drilling machines are actively used in factories and facilities where work with metal products takes place.

Specifications

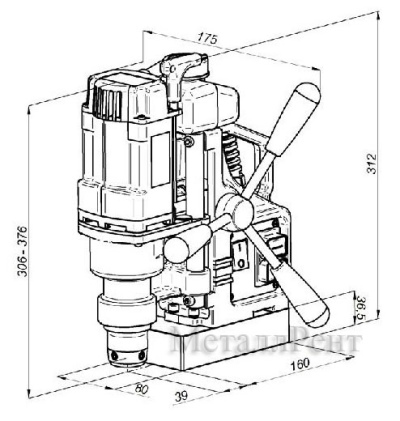

The drilling machine stands out for its light weight and compact dimensions. This is a key advantage of the equipment, which makes it possible to install and use the unit in places where large machines cannot be placed. Main technical characteristics of devices:

- average power - 600-3000 W;

- maximum rotational speed element - up to 1.1 thousand rpm;

- minimum metal thicknessat which fastening is possible - 6 mm;

- light weight, providing ease of use and transportation.

The size of the working area is ideally matched to the size of the magnetic cushion, ensuring perfect hold and quality work. To increase the safety of using the device, experts recommend using the special belts provided in the kit.

Most of the new models of magnetic machines are mobile-type devices that can also be fixed on almost any surface using the suction cup provided in the kit or other accessories.

Views

The construction and industrial equipment market is represented by a large selection of various equipment. Machine tool manufacturers regularly update catalogs with new, improved devices.

By spindle feed method

All machines responsible for the formation of holes are divided into models, where the feed:

- manual typewhen the unit is turned on through the efforts of the user - rotation of the steering wheel;

- automatedthat comes into action by launching certain systems.

The second option increases the drilling speed by 30%, which makes the equipment more popular.

By layout method

Devices are divided into the following types.

- Vertical... The spindle is located in the corresponding plane relative to the main structure.

- Corner... A special type of portable machine tools with a horizontally placed motor. The motor is connected using a bevel gear and a vertical spindle.

The second option makes the device more compact, which gives access to drilling holes even in low rooms.

By drive type

A standard classification in which all manufactured models are divided.

- Electrical or electromagnetic. The most popular type of drilling equipment, the use of which is possible almost everywhere where there is no particularly dangerous mode of operation.

- Pneumatic... To turn the device into operation, the energy of compressed air is used - the easiest way. The equipment is installed mainly where it is impossible to use electrical units. Also, the machines are in demand for work in places of increased danger, where it is necessary to comply with special requirements. This is explained by the type of structure assembled from alloys that prevent the formation of sparks when parts interact.

- Hydraulic... The principle of operation is based on the use of a hydraulic motor with a plate, which, thanks to the compressible oil, forms the required pressure. To assemble the structure, manufacturers use anti-corrosion alloys, which opens up access for installing machines in rooms with high humidity.

Despite the variety of models, all machines tend to heat up during operation without interruption. Therefore, modern devices are additionally equipped with a cooling system, which implies exposure of heated parts to a large amount of water stored in a special compartment.

The presence of such a system made it possible to extend the service life of the machine structure and prevent premature equipment failure.

Top manufacturers

The construction equipment market is represented by a large selection of magnetic drilling machines. Among the wide variety of manufacturers, it is worth highlighting several of the most demanded companies.

- DeWalt... The American manufacturer produces high quality machines with a long service life. The equipment is assembled from durable materials, coated with protective compounds and resistant to external influences.

- Metabo... A company from Germany, renowned for the production of reliable drilling machines. In addition, the company produces a wide range of equipment and tools for equipping the construction and industrial sectors.

- BDS... The manufacturer assembles professional equipment - machines for installation at large facilities where work with large volumes is required. The head office and factory facilities are located in Germany, the manufacturer uses high quality elements and modern assembly technologies in its work.

- Euroboor... Manufacturer from the Netherlands, engaged in the assembly and production of machine tools on a cushion of magnet. Additionally, it produces crown cutters - accessories for the main equipment.

- Magtron... The British brand produces high quality magnetic machines. The company's models are equipped with a wide range of functions and electronics that monitor the drilling or cutting mode.

- Rotabroach... Another British manufacturer that produces compact devices that are in demand for core drilling. Additionally produces core drills.

- Enkor, Stalex, Proma... Manufacturers from China who have established themselves in the Russian market as a company producing reliable machine tools and other equipment for the construction and industrial sectors.

- "Knight"... A domestic company that uses German components to assemble machines.

- "Vector"... A manufacturer from Belarus, offering consumers equipment at an affordable price. At the same time, the quality of the machines is up to the mark.

- "High tech"... The company from Russia is known for the production of high quality machine tools and a long service life. Most of the manufacturer's models are equipped with a speed controller and reverse. The company regularly updates and improves its assortment.

The models of the listed manufacturers are distinguished by their reliable performance. Therefore, when choosing a magnetic unit, it is worth paying attention first of all to the equipment from the list above.

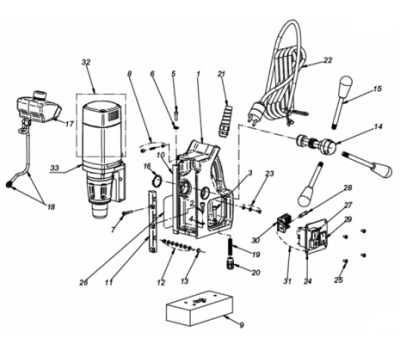

Additional accessories and components

When purchasing equipment for forming holes and performing other technological tasks, it is worth considering the need to purchase additional elements. Some accessories extend the functionality of the devices. Among them:

- Coolant designed to extend blade life by reducing frictional force;

- capacities of various volumes;

- magnets for rotating the device;

- vacuum installations;

- cartridges;

- core drills.

- taps.

Additionally, experts advise taking into account the material from which the blades are made.

- High speed steel. Suitable for purchase if you plan to create holes up to 35 mm in diameter or require processing of low strength material.

- Solid carbide drills, cutters. Suitable for making holes larger than 35 mm. The blades are additionally used for processing materials with high strength characteristics.

The choice of components should be approached carefully, since the quality of processing of steel products and the service life of equipment depend on them.

Selection Tips

Buying a magnetic drilling machine for processing pipes and other products requires a responsible approach and taking into account the following criteria.

- Dimensions of the structure. Large models are installed in large-scale factories. In turn, small machines are useful for making holes in hard-to-reach areas.

- Sole size... One of the important parameters that will determine which workpieces the installation can work with.

- Installation type. Manufacturers produce devices with horizontal and vertical installation. Before choosing machines, it is worth clarifying how best to install the equipment.

- Electric motor type. Power determines the drilling capabilities of the unit, so this point cannot be ignored.

- Spindle type and cutter rotation speed. The higher the indicator, the better the quality of material processing. At the same time, experts recommend giving preference to models where the speed can be adjusted.

- Drilling diameter. Magnetic machines have a maximum and minimum diameter of the hole being formed.

- Maximum allowable head force. Considering this criterion will reduce the risk of unexpected device failure. The presence of a system that takes into account the pressure will allow the equipment to be shut down in a timely manner if it starts to work above the maximum loads.

Taking these criteria into account will simplify and speed up the selection of a suitable magnetic machine for drilling holes of the required diameter or processing material.

The comment was sent successfully.