What are the types of drilling machines and how to choose them?

The organization of industrial production is unthinkable without studying what drilling machines are and how to choose them correctly. We'll have to get acquainted with the device of such a technique, the features of horizontal drilling machines and coordinate samples, multi-spindle and other types. A separate topical topic is the quill for rail drilling machines and other accessories.

Device and principle of operation

The very name of the drilling machine shows the key purpose of such equipment - it is used for drilling holes in various kinds of materials with different hardness and other qualities. The main functional link is a special drill. Most often, drilling machines are used in serious industries. Only a small fraction of these important devices are found in home workshops and educational institutions. But it is most convenient to consider the main parts and the scheme of work just by the example of household models.

By their principle of operation, they do not differ from industrial ones, but they are usually more universal, although they lose in the level of performance. The key nodes of such a machine will be:

- spindle headstock (the chuck is fixed on it, where the drill is screwed);

- drilling head (already holding the headstock itself and an electric motor with a mechanical drive);

- column column, thanks to which the drilling head maintains a predetermined position;

- massive flat bed.

It should be noted that this is only the most general description. In some designs, the device can be quite different, especially if we are not talking about vertical, but about other types of machines. In order for the spindle to be exactly in the right place, it is progressively moved ("served", as the professionals say). The machine itself is either simply put on a support by the bed, or fixed with bolts on the workbench. The power of the electric drive varies greatly depending on the class of equipment.

In household appliances, it is 0.25-1 kW. The unwinding shaft translates the movement to the spindle using a belt mechanism. A more or less advanced machine allows you to adjust the twist rate of the drill. In this case, pulleys with several positions are used to roll the belt.

The chucks for household drilling machines usually match those used for electric drills; the principle of operation and methods of reconfiguration are the same.

An important characteristic is the machining height (workpiece thickness). For household equipment, it is often only 2 cm. Only the most advanced household models are capable of working with 9 cm parts. Precise adjustment of the drilling height is important. They always try to design heavier beds so that they stabilize the apparatus and dampen excessive vibration.

An almost indispensable element is the feed mechanism of the drill, fixed in the chuck, directly to the material. Most often this is a feed knob. The control of the electric motor is separate from the control of the machine itself. Machines intended for small workshops are usually designed for a voltage of 220 V. Any more or less developed apparatus has a reverse mode.

Views

Vertical drilling

This version of the classification of drilling equipment is very common.The last numbers in the marking of such machines usually show the diameter of the drilled area. The technological capabilities of vertical drilling equipment are very wide. The difference between its models is expressed not only in size, but also in equipment. Often such devices are preferred for large-scale production.

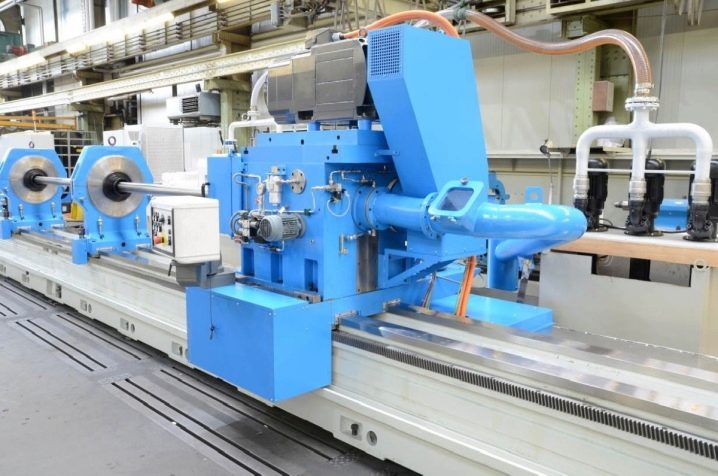

Horizontal drilling

These types of household and industrial drilling devices are suitable for a wide variety of materials. They confidently drill long pieces and prepare holes of considerable depth. These properties are very valuable in heavy engineering. It will be possible to work with bridge supports and structural units of dams. The horizontal placement of the drill is quite attractive from the point of view of countersinking, milling manipulations.

Radial drilling

Such devices drill, countersink and bore holes. Their most important feature is the base plate. A stand with a fixed column is placed on this slab. The turn along the guide sleeves sometimes goes up to 360 degrees. Shift in vertical and horizontal planes is possible; lead screws simplify the formation of threads with a given pitch.

Multi-spindle

This group can no longer include hand tools. The varieties are designed entirely for use in solid industrial production with maximum productivity. Additional spindles simply allow you to machine 2 or more workpieces at the same time - and usually at several different points. Plants and factories often buy double spindle metalworking machines. Often, this technique creates symmetrical holes and processes them.

The purpose of rail drilling machines is clear from their name. Among them, there are models designed for field or purely stationary use. The second type is usually more productive, more massive, but at the same time it does not tolerate the effects of weather conditions. The Jig Drilling Machine can drill and ream solid material. With its help, workpieces are also countersinked, holes are reamed and bored. Taking into account the large weight and dimensions of industrial drilling equipment, it usually provides for floor mounting.

Drilling machines for wood are often found in home workshops. However, they are also a common attribute of an impressive woodworking industry. The manipulations on such equipment are the same as on machines for metal processing. In the same way, there is a division according to the horizontal or vertical type of influence. The grooving option - along with the preparation of holes - is also able to select grooves, hence its name; this property is very valuable for the subsequent connection of parts according to the thorn-groove type.

On a boring machine, through and blind holes can be obtained. They also countersink and unfold the workpieces. With this technique, it is convenient to cut a disc from sheet material. The main parameter here is the largest conventional drilling diameter. Drilling machines for a drill are no longer an industrial apparatus, but rather equipment for a home workshop, and they are often made by hand.

But there, such a device turns out to be a very valuable assistant for:

- polishing car and motorcycle bodies;

- glass polishing;

- sharpening of knives and drills;

- grinding concrete.

Deep hole drilling machines are a very special category. They are often equipped with ejector drills. Deep penetration is considered to be 5 cross-sections of the hole and further. In this case, the channel diameter itself is relatively small. Chips in the process of work are removed non-stop, and the installations themselves are mounted and changed very quickly.

Top Models

It is appropriate to start rating description with model "Instar" CCB 63500... This device has special mounts for the work surface. The fixation is performed as reliably as possible.The basic configuration allows you to start working immediately after installation. There is no particular noise during the operation of such a machine with a durable body.

The work table is comparatively small. Technical specifications:

- power - 0.35 kW;

- net weight - 13 kg;

- 5 functional speeds;

- the supply of lubricating and cooling fluid is not provided;

- the spindle taper is of the MK-2 type;

- reverse is not provided;

- working platform - 16x16 cm;

- asynchronous electric drive.

An alternative is Patriot SD 370 model... Thanks to the cleverly designed handle, lowering and raising the spindle is easy. The body perfectly protects the working units from mechanical deformation and water penetration. Such a machine weighs 12.5 kg. Its base is well-designed and vibration-free.

Overloading is almost not terrible. The model is designed to work with both metal and wood. The only problem is the complicated replacement of the tooling. The cartridge is made according to the key type. There are 5 working speeds, and the weight of the device will be 13.6 kg.

Elitech STS 3 in terms of its characteristics, at least it is not inferior to the models just described. He confidently works with wood, metal and plastic. You can vary the spindle speed from 290 to 2580 in 60 seconds. An electromagnetic switch is provided. A special lighting system allows you to work even in places with insufficient source lighting.

The table tilts up to 45 degrees to the right and left. Thanks to the screen, the spread of chips and sparks is excluded. The designers have provided for a laser guidance system. To operate the machine, you need a voltage of 220 V. In general, a reliable and safe product is obtained, the only drawback of which is a rather weak casing.

You will have to pay more for a modern professional device. In this case, Euroboor ECO can be an excellent choice. 60S. For simplified management, a special coordination panel is provided. The engine power is noticeably higher than in the previous case - 1.6 kW. The machine will be moved in a proprietary case; it also comes with hex keys, a safety chain, etc.

Fortezzo SCY-42HD works from the household power supply completely calmly. A wide range of materials can be drilled on such a machine. Its important features will be:

- current consumption - 1.7 kW;

- the only available speed;

- the largest drilling diameter - 5 cm;

- 19mm Weldon format cartridge;

- working speed - from 100 to 730 revolutions.

It is quite reasonable to complete the review at Bosch PBD 40... An advanced manufacturer has provided control using a special display. The quality and accuracy of the assembly does not cause any complaints even from the most picky consumers. The built-in laser turns out to be very useful in practice. Basic properties:

- current consumption - 0.71 kW;

- 2 working speeds;

- work with steel blanks up to 1.3 cm thick;

- work with wooden blanks up to 4 cm thick;

- keyless chuck.

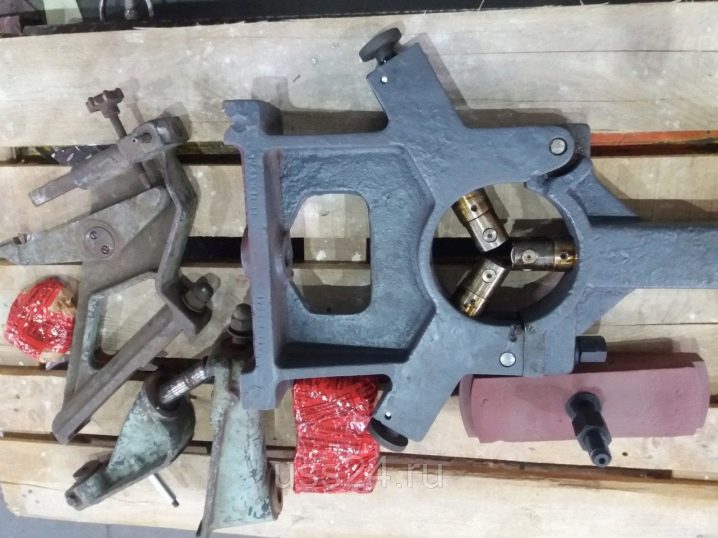

Spare parts and components

In addition to rail drilling quills, drilling equipment and attachments can require a variety of other parts for repair and maintenance. Additionally, you often need:

-

balancing drums;

-

tailstock;

-

bed;

-

cams;

-

lead screws;

-

pulleys;

-

lunettes;

-

bearings;

-

spindles;

-

hydraulic preselector drives;

-

friction clutches;

- racks.

Selection Tips

Horizontal boring machines are used for deep hole drilling. It is they who are in demand in the firearms industry. Vertical models are used for processing small batches of parts. Radial devices are preferred for handling large, heavy workpieces. Magnetic soled devices are usually automated and electronically controlled.

It is necessary to pay attention to other points as well. So, the power of the motor directly determines the performance of the machine.The more spindles, the higher the total productivity. Additional nuances are:

- number of speed modes;

- spread of diameter and depth of drilling;

- floor or tabletop mounting type (determining the permissible size and weight of the structure);

- current consumption;

- mains voltage;

- main and auxiliary functions;

- the cost of the machine (the more perfect and powerful it is, the more expensive it is).

Work rules

Simply choosing the right drilling machine is not enough. You also need to be able to use it correctly.

It is necessary to drill both wood and metal with a well-sharpened drill. If it is in poor condition, it will have to be refilled or refilled before use. For checking, templates or goniometers are used.

Do not start drilling without checking that the drill is secure. All large workpieces are firmly fixed on the machine table. Smaller parts are fastened in a vice of various sizes. It is useful to resort to a core hole before starting drilling. The speed of passage is determined by:

- features of the material;

- spindle torsion frequency;

- the specifics of the hole being created.

It is very important to have the correct automatic feed rate. It is highly undesirable to deviate from it. If a jig is used, then the workpiece must be firmly attached to the jig or the jig itself to the workpiece.

Steel parts are drilled only when using a cooling lubricant. A coolant must not be used for working with cast iron.

When working, hair must first be tucked under a headdress. The sleeves must be fastened with cuffs or rolled up. Excessive pressure on the drill is unacceptable. Do not approach any part of the body to the drilling area. The shavings should never be blown away, they can only be swept away.

When preparing to work on the machine, it is necessary to check the serviceability and quality of the equipment grounding. Any gears must be protected with a reliable casing. It is unacceptable to hold the parts with your hands. When you need to replace equipment or tools, you need to wait until all parts have come to a complete stop and turn off the machine.

The transfer of belts between the steps of the pulley when the engine is running is unacceptable.

Fragile materials should only be drilled with protective goggles. After finishing work, the machine and the area around it are cleaned. Workpieces and tools for their processing are stored strictly in certain places. The lubricant is used only in accordance with the instructions. A worn-out tool must not be used.

Drilling should be completed very carefully, since this is the most crucial moment. When the drill is withdrawn, the feed is reduced. Large pieces of wood can only be drilled on board scraps or plywood pieces.

If the power goes out during operation, the machine must be de-energized. The workplace must be spacious, and adequate lighting must also be maintained.

The comment was sent successfully.