All about planing machines

Everything about planers can only be found in scientific research or textbooks used to train specialists. The choice of the appropriate type of equipment is carried out depending on the task assigned to the employee. There are special machines for working with wood and metal, which are differentiated by design features and principle of operation, by universality or specialization, by the number of possible actions.

Peculiarities

In the application manuals, you can find a detailed explanation and differentiation of units that fall under the general definition of "planer". It is believed that their use is optimal in mass production. But recently, units have appeared that can be used in a home workshop. The simplest differentiation of the extensive range from manufacturers: machines for wood or metal.

The number of species does not allow the development of a single classification, therefore, in the search for the desired device, you can be guided by variable characteristics, your own priorities, occupation or production needs. Let's take a look at a few common categories.

- Units of general purpose (universal) are the most common group of planing equipment.

- Another category is specialized machines, they are divided into longitudinal and transverse ones according to their design features. They process parts of different caliber. The difference lies in the way the workpiece moves, moving and fixing the cutter, cutting off the metal during translational motion. These include edge planers, which are necessary when processing sheets of a relatively large plane and non-standard parts.

- Special machines are optimal for mass production because they have a limited number of possibilities. But with a significant amount of output, they accelerate and facilitate the increase in the rate of production, allowing you to do a certain number of operations at the intermediate stages of the overall cycle.

Differentiation of this group can be made by other distinctive features, for example, by size (small, large and medium), by the type of drive (mechanical or hydraulic). The purchase of a planer requires taking into account other features of the device:

- productivity;

- working speed;

- maximum effort;

- overload protection systems;

- the size of the part that the machine is able to process at the limit of its capabilities.

When buying, you need to pay attention to the types of installation: planing machines are of a stationary type and table-top. The former are purchased for woodworking enterprises with a substantial volume of products, the latter are good for home workshops, because they are significantly lower in cost.

Views

The types of machines can be very conditionally differentiated into models used for processing wood or metal. Each of the groups has separate varieties:

- among the specialized options there are units with a movable and retractable carriage, as well as a pit and edge planer;

- the intermediate group includes molding models that perform profiling and planing;

- broaching machines are divided into horizontal, vertical and others (and specialized too);

- gear shaping can be milling, shaping and gear shaping (with numerous narrower varieties, ranging from lapping and haulage to rounding and honing).

The four-sided woodworking planer is a great way to save time when machining woodworking parts. The number of work items on such devices starts from four, but can be large. A complex design means performing not only one type of work, but also several different ones: from planing and milling to profiling and thicknessing. The main criteria will help you to choose the right 4-sided machine and significantly reduce your time costs:

- the feed rate of the lumber and the system that is used for this;

- dimensions and mobility of the unit;

- processing power;

- functionality;

- withstand load.

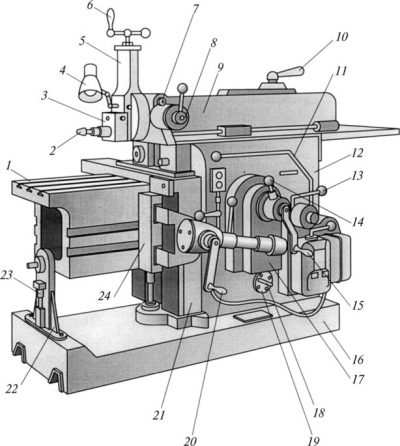

The diagram will showcase working tools, feeder, control and safety system.

Cross planing

They are named so because of a slider with a caliper that moves in the longitudinal plane. This feature is provided by horizontal guides. The working table of the unit moves along the guides in the vertical plane. The bed, which plays the role of the foundation, is securely fixed. Inside its body there is usually a rocker, gearbox and drive, and under it is a tray for collecting grease.

The six-speed variety is very common. This is due to the narrow target designation.

Cross-planers are intended for home workshops or small repair shops, less often used in small-scale production. They are necessary for processing workpieces of small parameters.

Longitudinal planing

Designed by developers for processing larger workpieces. They are compared to milling machines, but the quality and cleanliness of the planers will be better. The movable work table moves the workpiece to the fixed cutter, making a forward and backward motion. The metal shear is carried out progressively, and the reverse movement takes place in idle mode.

The rigidity of the structure is a distinctive feature by which machines of this type are differentiated. It is provided by the presence of one or two racks. The subject of preference is selected according to the type and size of the workpieces.

Types

The generally accepted classification of machine tools classifies planers in the seventh group. The cipher used in industrial production, nomenclature and typing invariably begins with the number 7. Machine tools are distinguished on several grounds.

- By the used drive. These are hydraulics, crank-rocker, unit with constant or variable speed of moving units.

- By the number of working surfaces (and power). One-sided is usually small, and two-sided, working from opposite sides, are inferior to 4-sided.

- Drive power determines size and functionality: household is good in a home workshop for periodic work, and manual - for limited needs.

Typification can be performed in terms of speed, smoothness, frequency of movements, number and type of incisors (and this is both productivity and quality of work performed). Regardless of the type of unit purchased and its cost, all safety and installation rules specified in the manufacturer's instructions must be observed.

High-quality processing is carried out only on a machine that is installed in accordance with the requirements, adjusted and operated by a person with a certain amount of professional knowledge.

Automatic

Equipment used in serial production. It has several nodes connected by additional mechanisms. Machining takes place with the help of a CNC system, while the parts are fixed on a solid cast bed.

In modern reality, there are devices equipped with additional elements: cooling, a modernized control system and even a conveyor to which workpieces can be fed.

Mechanical

This involves the execution of operations using manual force. They are inferior to automatic processing in terms of functionality, accuracy, surface roughness and productivity, but they quite cope with their duties in a home workshop or with a small amount of work for narrow needs.

Model rating

In the above TOP-3, the main criterion is the demand from the consumer, who is guided by his own priorities when choosing a machine for permanently carrying out several processes or narrowly focused activities. This includes the following models.

- Planer PATRIOT WW 160 8 kW. It is simple and convenient, reliable and guaranteed for a long time. Has the ability to collect waste in a special casing. Users note the excellent build quality of the unit and the affordable cost.

- Planing and thicknessing machine "STAVR SDSR-2/1700" 1.7 kW with variable planing capability, manual and automatic feeding of workpieces, automatic shutdown in case of overload. It is quick and easy to install, safe and reliable.

- Surface-thicknessing machine "BISON SRF-254-1600S" for 1.6 kW are distinguished by a spacious cast table, efficiency and ease of use. Automatic feeding allows processing 6 m / minute, there is a separate hole for dust extraction.

Price is an important, but not the main condition. The main thing is that it is in harmony with the quality of workmanship, long-term work and meets the urgent needs. Often you can pay a hefty amount just for the name of the brand or save money by buying a wonderful product from a domestic manufacturer, without paying for someone else's transportation and customs clearance. In the above models, the price can be considered an additional advantage and harmonizes pleasantly with performance and functionality.

How to use?

The manufacturer's manual contains detailed instructions that may differ when working on different types of machines. Installation depends on the dimensions of the bed, the recommended type of attachment and the location where the unit is to be installed. The adjustment is described in the instructions and is determined not only by the type of equipment, but also by its functional characteristics.

Before starting work, you need to set up the transmission mechanism and do this in accordance with the features of the transmission mechanism, check the clamping of the workpiece, the contact of the tool with the surface, adjust if necessary.

If a person intends to install a planer in his own workshop for the first time, it is better to do this with the assistance of a specialist who will show you how to correctly position the knives, talk about safety precautions and demonstrate the operation of a functional device.

The comment was sent successfully.