Features of thicknessing machines

You need to know the peculiarities of thicknessing machines when organizing a full-fledged production. It is necessary to find out what they are for, and what they are, what they do. The rating of the best woodworking machines for the home workshop and other applications deserves attention.

Additionally, you should deal with double-sided and other models of thicknessing machines.

What is it and what is it for?

Usually a thickness planer is a woodworking equipment belonging to the subspecies of planing equipment. With its help, the workpieces are planed precisely dimensioned in thickness. Basically, the thicknessing machine works with parts that have been planed in advance on the planing technique.

The main purpose of the thicknessing machine is the production of various products from a board or a bar. And it is also often used to process other wood raw materials. This machine is designed to produce parallel surfaces on workpieces. As a result, the parts will have smooth edges and the required cross-section.

After processing, all irregularities and roughness are eliminated.

It should be noted that such a device is not suitable for calibrating objects by thickness.

In the woodworking industry, thickness planers can be used everywhere. Advanced enterprises use a combined planer and planer equipment. The width and thickness of the processed structures are set with an error of about 1 mm. Everything that the thicknessing machine does is powered by an electric motor. A knife shaft is attached to such a motor. The working surface and a number of special rollers are adjacent to the shaft. Manufacturers produce equipment with a variety of types of equipment.

The difference may relate to power, rotation rate, overall dimensions. The typical working principle is flat planing. The workpieces will be held on the working surface using specially thought-out mechanisms. Only after fixing do the shaving itself begin. Automated machines can plan wood at a significant speed, and this speed is individually adjustable. In most cases, the planing depth is 14.5-15.5 cm.

Work tables are made of wood and are meticulously sanded. The standard length of such a table will be 10 cm. The table itself and the shafts are usually attached to cast iron supports. The stability of the equipment depends on them. The beds are attached to the work table with clamps. In order for the motor to drive the functional parts of the machine, it is supplemented with pulleys, belts, and drive chains. Powerful devices use 2 electric motors.

The special screw is very important. It determines the caliber of the planer. The rollers are clearly divided into 2 pairs. In thicknessing machines, a dust and sawdust suction system is used. Sometimes a simple industrial vacuum cleaner is used instead. There is also:

- top and bottom nodes;

- pressure block;

- sled (guide element).

Views

By design

Thicknessers for wood are divided into several types. The household option is small in size. This is usually light and simple equipment. Its transportation is not difficult, including by car, if necessary. You can place such a model in a small room. The power will turn out to be relatively small, at best average.

True, in many respects the advantage is the relative cheapness. A household machine can perform a number of significant sawing jobs, including cutting to a depth of 0.15 cm or processing small workpieces. Automatic feeding is unlikely to be found in such equipment. It is possible to work on universal woodworking machines for the home only with significant physical effort, and even this will hardly allow you to cope with a deep cut.

A modern industrial thicknessing machine is a much more powerful and high-speed equipment. It works with high precision thanks to the control unit. This technique can cut a tree very deep and sometimes feeds the parts automatically. An industrial thickness gauge takes up a lot of space in comparison with a household one and weighs significantly more. It can be connected to the mains and equipped with a special cooling system. It is worth paying attention to the combined planer-thicknessing machine. Such a solution allows the production of particularly precise parts or an exclusive product.

It will be possible to exclude the appearance of any defects on the surface. Many combination devices have a reciprocating motion option. Such equipment is produced by both Russian and European firms, and new modifications are made every year. The planer-thicknessing machine is capable of milling wood. As usual, processing is carried out at the expense of the cutterblock. The planer-thicknessing machine is equipped mainly with sharp knives, which cut wood very efficiently. Among them there are both household and professional models. Changeover is very easy.

By the number of cutting edges

The equipment is divided according to the number of shafts. Single-sided models are equipped with a single cutterblock. They only machine the top plane of the workpiece. The double-sided unit has 2 working shafts, one of them is placed from below. This solution allows you to machine the lower part of the parts. Double-sided machines start working precisely from the bottom surface of the workpiece.

Such models have a wide range of functions. Single-sided versions are mainly needed for simple homework. Three-sided and four-sided models are versatile and multifunctional, but only find application in industry. Sometimes they perform manipulations from several sides at the same time.

Rating of the best models

- It makes sense to start the review with a fairly light machine that is sold at an affordable price. "Caliber SSR-1600" able to cut a piece of wood in accordance with the given dimensions. It will also flatten the surface if you turn on the planing mode. The thickness of the workpieces can be 0.6-12 cm. Other features:

- parallel fixing stop as standard;

- changing the angle from 90 to 120 degrees;

- rubberized feet for increased stability and vibration damping;

- turning frequency of the cutting part up to 8000 rpm;

- equipping with roller rollers that improve the feed of the workpiece;

- manual feed in planer mode;

- the ability to load the electric motor without interruption for no more than 20 minutes in a row.

- The solidity of the case and the presence of a folding table testify in favor of the model "Craton WMT 318". Although formally it is produced under a Russian brand, in fact, production is at a Chinese enterprise. However, this can hardly be considered a disadvantage - rather the opposite. A lightweight, small-sized device can confidently work with a bar and other workpieces in ordinary home practice. The comfort of the handles and the solidity of the structure make it much easier to carry. The automatic feed can run at a speed of up to 8 m per minute. The speed of rotation of the working shaft reaches 8000 turns in 60 seconds. The parameters are adjusted very smoothly. The tilting table guarantees the processing of elongated workpieces. Adding additional clips plays the same role.

- One of the best home workshop machines is JET JWP-12. The productive machine, again, is made in the PRC. The device weighs 30 kg. The largest size of the workpiece, including the timber, will be 15.3x31.8 cm. Only 1 button is provided to control the device, and the shaft rotation speed reaches 9000 turns in 60 seconds.

- The top of the best models includes Hitachi P13F... Such a device is great for semi-professional work. The planing depth ranges from 0 to 0.24 cm. The cutting height can reach 15.24 cm. Excellent performance is achieved thanks to the proven 1.8 kW motor.

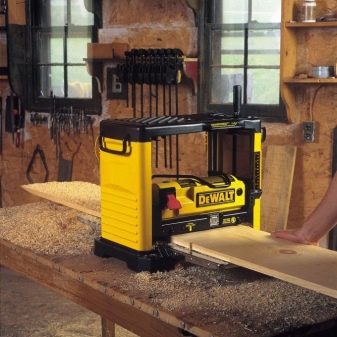

- When choosing equipment for professional use, you should pay attention to DEWALT D27300. This American product has a very high cost, but it does work at a very high level. The drive power reaches 2.1 kW. The greatest thickness of the workpieces to be processed is 16 cm. Two work tables are made of high-quality milled aluminum, and the parts are fed at a speed of 5 m per minute.

- PATRIOT TP 255 planes the boards extremely cleanly. The product will feed automatically. Two internal knives ensure precise processing. The result is a flat and completely smooth workpiece. The steel body is protected from corrosion with a special protective paint. The rotation rate reaches 8000 rpm. When idling, this thicknessing machine moves at a speed of 6 m in 60 seconds. It is possible to plan wood to a depth of 0.25 cm. Processing of both hard and soft woods is possible. The 1800-watt motor is reliably protected from overloads, and the device as a whole lasts a long time.

Components

Predictably, planers are equipped with work shafts and knives that are mounted on these shafts. However, they also require a variety of other parts, such as:

- chains;

- stators and rotors;

- rubber rollers;

- gauge rods;

- motor housings;

- pulleys and gears;

- gear covers;

- transmission shafts;

- brackets;

- machine tool fences;

- pulley nuts;

- knife drums;

- slip bushings;

- spacer rings;

- brush holder covers;

- ball bearings and V-ribbed belts;

- electronic blocks, strips and damping pads.

Nuances of choice

The thicknessing machine should be chosen very carefully. We must not forget about the cost of such products. Very cheap samples are not able to reliably process more than 3-5 cubic meters of wood per season. They can fail at any time. The most affordable devices are suitable for one-time repairs and infrequent use.

It is important to pay attention to the space occupied. The thicknessing machine requires a significant amount of space for operation and storage. Normally, the device should be accessible from all sides. It is also necessary to check the convenience of feeding the workpieces. Another significant characteristic is the longest length of the planks to be planed.

Among the technical parameters, the following are especially relevant:

- total cutting depth;

- shaft torsion frequency;

- productivity (the more it is, the higher the equipment power should be);

- weight of equipment.

The comment was sent successfully.