Thicknesser JET

The range of high-quality and multifunctional machines is currently very large. Excellent devices are produced by the well-known company JET. In this article, we will get acquainted with the characteristics of modern thicknesser machines from this manufacturer.

Peculiarities

Modern models of thicknessing machines are presented in the widest range. The devices of the well-known JET brand are distinguished by very good quality.

The company's equipment is in great demand, since it has a lot of advantages.

-

All JET brand equipment is characterized by perfect build quality. Due to this, branded equipment is durable, reliable and wear-resistant. High-quality machines do not require frequent repairs if you use them strictly according to the instructions.

-

The JET planers do an excellent job with their main duties. With this type of equipment, users can handle large quantities of materials without any problems.

-

The technique in question is very simple and straightforward to use. The operator can quickly figure out how to operate it correctly. In addition, thicknessing devices are completed with instructions for use.

-

JET brand equipment can be supplemented with many useful options and functions. The thicknessing equipment has the ability to automatically shutdown, which indicates a high level of safety of such equipment.

-

JET equipment is manufactured from high quality and reliable materials. For example, the working surfaces of the machine tools are made of practical stainless steel.

-

The brand's high-quality machines demonstrate the highest precision in material processing.

-

JET branded devices are presented in a rich assortment. There are many different variations of practical and functional machines for the choice of consumers. Among them there are both woodworking and combined options.

JET proprietary machine tools also have their drawbacks.

-

Most branded devices are quite noisy. Unfortunately, these devices do not come with special headphones.

-

The lion's share of JET machine tools is very expensive.

-

JET planers are very heavy.

-

If the equipment breaks down or needs to be replaced, it can be difficult to find the right parts.

-

Some models of the company's machine tools do not have the highest power level.

Range

A large manufacturer produces many high quality thickness planers. Buyers can choose a model that is cheaper or more expensive. Hardware functionality also varies.

Let's take a closer look at the characteristics of some of the JET machine tools.

-

JPW-15K 230B 10000283M. A high-quality model that is designed for processing large-sized wooden blocks and boards. The engine of this machine is located in the lower pedestal to make the access to the planer shaft more convenient. The voltage of the device in question is 220 V.

The design of the machine itself is highly reliable, massive and practical.

- JPW-15K HH 400B 10000284T. The voltage of this machine is 380 V. The depth of planing here can be from 2 to 5 mm. The equipment is designed for wood processing. The design of the equipment has a special work surface made of ductile iron.

And also in the machine under consideration, a special lifting mechanism is provided for ease of transportation.

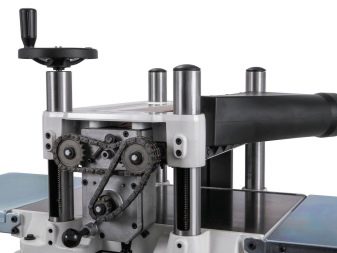

- JPW-208-3 708584T. Popular unit with high efficiency. At the same time, the machine is characterized by small dimensions, suitable only for small industries. In the apparatus under consideration, a light feed of workpieces is assumed, and the feed rate can be adjusted. The machine is made with a chain drive.

- JWP-15B 722150-RU. A quality model that is ideal for a small carpentry workshop. This device has the ability to install the Helical shaft. The operator can adjust the feed rate at his discretion. Access to cutting parts is simplified as much as possible.

- JWP-15K HH 230B 10000284M. The voltage of the machine in question is 220 V. The permissible depth to which the machine planes materials reaches 2-5 mm. The main working units here are made of ductile iron.

The device has a special lifting mechanism. The set includes a special pedestal-stand, with which the unit can be installed on the floor.

Instructions

JET brand equipment must be used in accordance with the instructions. The operating features of all units are different. It all depends on the capabilities and functions of various types of devices.

Let us consider the general rules for the operation of thicknessing equipment on the example of the JWP-15K HH model.

-

The device is designed for wood processing. Working with other materials is allowed only in exceptional cases. Before that, it is advisable to consult with representatives of the production.

-

Wooden blanks are required to be installed on the countertop. They must be secured and served using only safe working methods.

-

The machine in question can only be used by those personnel who are well familiar with the methods of maintenance of the equipment, work on it.

-

In the course of work on the considered model of a branded machine, all safety elements and protective fences must be placed in their places.

-

Changes to the JWP-15K HH are not permitted.

-

It is necessary to check the condition of the branded equipment on a daily basis, to monitor its performance.

-

If work is planned with the equipment, the operator needs to remove any loose items of clothing, hair should be removed. Do not use the device with rings, ties, watches. Any jewelry and accessories must be removed first. The sleeves must be rolled up above the elbows.

-

The operator must wear safety shoes to operate the JWP-15K HH equipment. Sandals or beach options are not permitted.

-

It is always necessary to use certified personal protective equipment when operating brand equipment.

-

Gloves must not be used when working on the machine in question.

-

It is necessary to check the stopping time of the original equipment. It should not be more than 10 seconds.

-

The equipment needs to be placed in a spacious place where the operator can freely handle materials.

-

The working area in the equipment must be well lit.

-

The thicknessing machine in question is adapted to work indoors. It must be installed on a perfectly flat and solid surface.

-

Initially, the user must make sure that the power cord of the equipment does not interfere with its high-quality and safe operation, does not interfere with other people.

-

When carrying out material handling work, the operator should never be distracted. It is important to monitor as closely as possible all actions taken.

-

If the equipment is not in use, disconnect the plug from the mains.

The comment was sent successfully.