What are the sawmills and how to choose them?

A novice craftsman who has mastered working with the simplest power tools - a grinder, a hammer drill, a screwdriver, a jigsaw, may not immediately continue working on a lathe and milling machine. But the next step in its development, perhaps, will be sawing blanks with a circular saw.

general description

Sawing machine - a fixed power tool that cuts workpieces from wood, as well as from metals and their alloys. By installing a circular disc, you can cut bricks or ceramic tiles at high speeds. The sawing machine easily cuts plywood, planks, beams and laminates.

The second function of an electric saw, which has a saw blade in its composition, is often the ability not only to cut a board and a beam, but also to remove unequal sidewalls from the surface of such blanks (making edged boards from unedged boards), and also partially smooth out roughness and unevenness of wood.

But a circular saw cannot fully replace a jointer (including an electric one).

Views

According to the purpose, the sawing machine can be woodworking - sawing, planing, sawmill (full-fledged sawmill), format-sawing (mainly for wood, including pressed laminated chipboard blanks made of sawdust with glue), longitudinal-sawing, cross-sawing (making spacer cubes).

Desktop machines, as a rule, have a low power - up to 2 kilowatts of consumed electricity per hour. They are started from a standard single-phase network with a voltage of 220 volts and fit easily in the garage.

By type of cutting tools

By the type and type of cutting cutters, sawing machines are subdivided on circular (with a circular saw), with bending and strip saws... The bending saw moves straight or curved depending on the hardness of the wood species. The curved path of the saw is used in cases where the straightness of the cut is not important - for example, when you need to cut firewood.

If for wood you can use a regular saw made of high-speed or tool steel, then for processing stone, for example, granite, or artificial materials (slate, tile, concrete), you will need victorious or diamond tips.... So, to make door and window openings in a wall made of reinforced concrete, diamond sawing is used: only a coating of small diamond particles will allow cutting the strongest concrete and steel reinforcement, as well as cobblestones (granite), crushed stone.

Machines for metal use both abrasive "bulgar" discs of large format (22 cm and more) and saw blades made of high-speed steel... The teeth of the disc for metal are much smaller - large ones, on the contrary, would cling to the metal and lead to injury to the person performing this metal processing. Cutting steel perfectly cuts non-ferrous metals and alloys of the St3 type, but for processing harder alloys, for example, stainless steel 12X18H10T or frost-resistant "pipe" steel 09G2S, it is better to use a fiberglass abrasive, or diamond will win.

Due to its viscosity, stainless steel is difficult to saw - on an industrial scale, it is better to use laser cutting on a CNC machine than to use conventional electric saws. Typically, the saw drive with a circular saw is mounted on a frame or directly under a workbench table that has a slot for that saw. Carefully adjusted guides are installed on the upper surface of the machine or workbench table, thanks to which the timber or board does not slip.

Removable guides are secured with clamps or mini-vices. It is impossible to move them when passing a board or a bar through the sawing gap - these guides withstand the standard force applied by the master to smoothly push the board along the sawing space. It is more expedient to move the guides than to move the drive itself: the latter must be rigidly fixed, and the disk must be absolutely motionless in its plane, it does not deviate by a millimeter.

The non-bending, thick disc ensures an almost perfectly flat surface on the sawn edges. In some cases, a sawing machine can even replace a milling cutter - it is possible to make a perfectly flat bar or piece of sheet from any curved block.

The main requirement is to cut this workpiece not across, but along the wood fibers: elements sawn exactly across, quickly break, split into small pieces. The only exceptions are wooden cubes and cubes.

By location

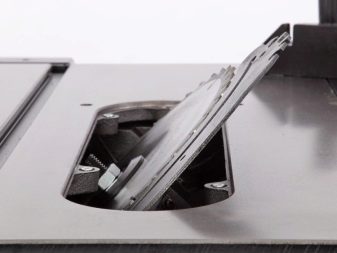

The location of the cutting knife can be horizontal and vertical. The same applies to single and double sawing machines. The number of circular saws can be any. They resort to circulars in cases when the jigsaw cutter is bent so much that it is impossible to make workpieces that are even in width and length: the workpieces deteriorate and are rejected one after another.

In vertical sawing of wood and lumber on its basis, you can do the opposite - move the drive along the guides manually or using a special running gear, and leave the workpiece motionless: from the point of view of sawing technology, there is no fundamental difference.

Rating of the best models

An overview of the best models is in the following list.

Metabo TS 216

This device is a tabletop model that can be carried in one hand. The model is suitable for sawing wood on the construction site. The device includes a high-speed motor equipped with an overheating sensor that allows the engine to be turned off in time. Its brake stops the motor in 3 seconds.

The protection system against restarting an overheated motor makes it possible to prevent burnout of the winding, and the smooth acceleration device extends the service life of the electric drive. The locking disc element allows you to detach a worn cutter within a few seconds and insert a new one in its place.

Makita 2704

Designed for a consumption of 1650 watts. The speed of revolutions is 4800 per minute. Sawing capacity - up to 91 mm... Works with plastic, wood and lumber, composite, artificial stone and non-ferrous metal. There are legs and corners to set the machine on a workbench. The device is suitable for a garage or utility room. Oblique cuts at an oblique angle are allowed. All the same circuits and functions of electrical and electronic protection of the drive and mechanisms are present.

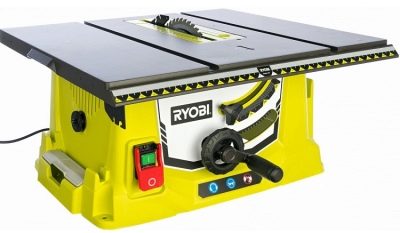

RYOBI RTS1800

Consumes 1800 W, has a die-cast aluminum sliding table top. This model works with workpieces up to 48 cm long. The cutting angle is changed using a protractor - in any direction up to 60 degrees from the vertical. Motor and drive protection systems ensure a long service life of the device.

Hitachi C10RE

A device for small-scale production of blanks. He cuts many types of lumber and composites. The machine is connected to the vacuum cleaner through the working chamber branch pipe. Saw blades with a diameter of 250 mm are installed on the device. The diameter of the landing gap is about 30 mm. The device produces a through-cut up to 73 mm.

When sawing a workpiece at 45 degrees, the width (depth) of the through-cut is already 63 mm.The machine develops a stroke of up to 4800 revolutions every minute. The object table has dimensions of 64x47 cm, and the 25 kg weight makes this machine portable and transportable.

"ZUBR ZPDS-255-1500"

Adapted for all work with wood and all kinds of wood composites... Works as a full-fledged sawing tool in the conditions of small-batch production of workpieces. The device of this manufacturer will partially replace the wood router and jigsaw. The unit works even with volumetric (shaped) workpieces due to the ability to produce combined cuts. The laser beam sets the cutting line along which the saw blade will pass.

Smooth setting of the speed of revolutions due to the electronic driver that controls the speed of revolutions is useful in the manufacture of more complex parts. The disc is not clamped thanks to the adjustable opener. The completeness of the machine is complemented by a device that is convenient to push the workpiece in the direction of the saw stroke, which saves the user from injury. The machine cuts wood with thicker workpieces.

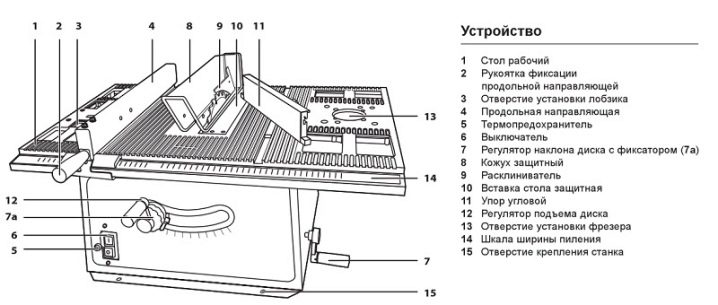

Components

The structure of the sawing machine, made by a master with his own hands, includes: a frame (bed), an electric drive, an increase or decrease gearbox with a flanged threaded axis, on which, like a Bulgarian abrasive disc, a saw blade is put on with the help of flanges. In the simplest case, control is carried out using a power switch and a button for feeding it to the electric motor; in a more complicated version, there is an adjustment driver or an electronic board with stepwise switching of revolutions.

It is possible to independently reduce the speed by half by connecting the saw unit in series through a powerful high-voltage diode with a supply of tens of amperes of operating current, however, such a switch will be accompanied by a transition from the maximum engine speed of the saw unit to one reduced one. For example, simple switching devices operate at 4000 and 9000 rpm.

To move a board or timber, as well as a sheet of plywood, guides with brackets or clamps are used, which act as clamps. Branded machines have a scale in millimeters applied within the working area. The element being cut on such a machine is shifted to the selected distance. More professional machines, including the two-saw version, allow the drive itself to be moved rather than the guides. A carriage is used for it. It moves the drive a distance selected by the machine operator.

In addition to the carriage, disks and engine, parts of the gearbox are also replaced - shafts with gears from which it is assembled. In direct drive machines, the shaft is replaced with the rotor. With a complete disassembly of the engine, in some cases, the stator also changes. The collector motor contains the rotor and stator windings, which work in mutual contact using brushes and rings.

The brushes change many times more often than the rotor and stator.

No less obligatory elements are a transparent fire visor, which excludes the scattering of incandescent particles that could cause a fire in the workshop.... Removal of shavings and sawdust is provided by a vacuum technical vacuum cleaner, which is connected to the network before the start of the drive and switched off after it. Both of these measures will keep the workplace relatively clean. The weight of the machine, not fixed to the workbench table top, is at least 30 kg.

Such dimensions are commensurate with a power of 2 kW. The machine will cope with boards and plywood up to several centimeters thick. Bench machines cut workpieces up to 1 m long and 80 cm wide.

They select such equipment for their immediate needs in the processing of wood and metals, as well as metal alloys.

A production mill - for example, a sawmill - will provide continuous operation up to 16 hours. The power of such a device is more than 10 kW. It cuts plywood with a width of several meters and is equipped with two or more saws mounted on one shaft of a high-power motor (or a drive with a gearbox). The sawmill operates at extremely high speeds - 10-25 thousand revolutions per minute, and the cutting of boards, plywood and timber is perfectly smooth. The mill passes through its working field up to a dozen simultaneous strips, which is why the sawing of a bar, board or plywood is accelerated many times over. He cuts chipboard, MDF, fiberboard, semi-synthetic board, non-metallic and semi-metallic composite. In fact, it is a multi-sawing machine controlled by a team of workers or an electronic on-board computer (CNC).

The productivity of sawing machines is measured in linear meters per minute or per hour. For example, a production mill has a through-cut speed of at least 2 m / min. On household devices, this speed is from several to several tens of centimeters every minute.

Nuances of choice

Household machines for the home - or rather, for the home workshop - are selected primarily by the number of engine revolutions. Machines with a speed of up to 2500 rpm are equipped with a V-belt transmission, which will help to repair the unit faster. Devices with higher speed are equipped with a gearbox that wears out faster. Gear machines weigh less because they take up less space, are easy to move, but require more complex repairs: gears and additional shafts are more expensive than a V-belt element and need regular cleaning and lubrication.

The dimensions of the table in the home (garage) workshop are limited to the dimensions of 1x2 m for the workbench. Some users prefer table-mounted machines: a cut is made in the table top for a rotating disc, then guides are placed for the cut for the required thickness and width of the cut elements.

Overload protection is a must - as well as protection against injury and dust (clogging) of the workplace with shavings and sawdust. A remedy for the latter is the ability to connect an external vacuum cleaner designed for cleaning small construction waste.

Planking of boards is carried out using special devices. For planing sawn boards or timber blanks, a special plane is used, the role of which is played by a cutter rotating on the same shaft with the saw (or independently)... The guides are set using a functional unit that provides thicknessing. The thickness gauge built into such a machine helps to precisely set the length and width of the plywood to be cut into segments.

Finally, power up to 2 kW is an indicator that no home workshop can do without. A higher level of power consumption reduces the scope of sawing machines to the conditions of a mini-factory or a carpentry shop, in which there are wiring with a large cross-section of wires and a three-phase network.

The comment was sent successfully.