Overview of planer-thicknessing machines and their selection

Often in everyday life, and even more so in production, wood is used, or rather its blanks. Making them with your own hands is very laborious, and it takes a lot of time. Therefore, planer-thicknessing machines are now becoming more and more popular, presented by many models and manufacturers on the market.

What it is?

This machine is very versatile, as it embodies two products at once - a jointer and a thickness gauge. The main purpose of the first is alignment of the workpiece. When a piece of board or wood of a certain shape has bumps and other irregularities on the sides or on its surface, the cutting element allows you to correct this. Also, the jointer is able to display the required angles for the material. The main purpose of the thickness gauge is to calibrate the part across the width and create the appropriate parallelism of the edges.

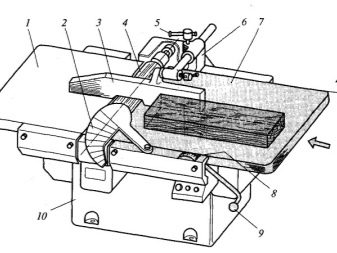

This type of equipment has its own design, consisting of several elements.... The first is the base frame. This stationary part is very important, as all other mechanisms are located on it. The bed must be very strong and stable - these are the main requirements when it comes to quality models.

Also, an equally important part of the structure is the work table, on which the workpiece is placed, secured and then processed. This element of the product is divided into two parts - the supply wood and the receiving one, where the final product is located.

The main processing is carried out due to the shaft on which the knives are located. During work, it is important to keep an eye on this part of the product, as it is the most dangerous and requires very sensitive handling.

All the driving force of the planer-thicknessing machine lies in the engine, which has certain power indicators. They often play an important role in the selection and purchase of equipment.

On the front or side of the machine there is a start button and main controls that allow you to change the parameters in accordance with the workpiece and what result the user needs.

It is this selection of elements that makes up the design of the machine. In addition, specific products can be equipped with other mechanisms, but this already depends on the model, equipment configuration and manufacturer.

Species overview

The main classification of planer-thicknessing machines occurs in the division according to the scope of application. So, the equipment is classified as a household (amateur), semi-professional and professional type. Accordingly, the higher the class of the model, the more expensive it will cost.

Household mini-machines are good because they have a low cost and are often small in size, which simplifies their operation and, in particular, their location and possible transportation. The functionality of these devices is very simple, but it is quite suitable for a summer cottage or home workshop, so as not to process the tree yourself and not spend a lot of time on it.

Semi-professional machines are quite popular, as they are in demand in various fields. Experienced users also buy them for the home, if everyday life is accompanied by frequent work with wood or it is an additional income.

Also, semi-professional units can become an excellent part of small production, where there is no need for large capacities and volumes of workpieces.... This type of equipment, in addition to the basic mechanisms, has a number of others that make the operation more efficient and varied. The cost of such products can be very different, but mostly refers to the middle range.

The professional class of technology speaks for itself - the best technologies and functions, a wide range of tools and high efficiency, thanks to which the production process allows processing many workpieces.

Such equipment is used only in production, because it is there that the machines will be able to pay for themselves with the maximum return.

Rating of the best models

Budget

Belmash JT-2 204/210 S091A - a good model that does its job reliably. The motor has a power of 1500 W, which is enough to work with workpieces of different quality. The planer shaft diameter is 51 mm. Power is supplied from a 220 V power system. The cutting element is represented by two well-sharpened knives. The design uses a belt drive. The maximum planing depth is 2 mm. The length of the jointer is 737 mm, the planer is 285 mm.

Weight only 29 kg, floor-standing installation. The bed is made of high quality materials, and its construction is prefabricated. The rotation speed reaches 9000 rpm, which allows you to work quickly and without delays. The rip fence is made of aluminum, there is an automatic material feed at a speed of 7 m / min. The cleanliness of the workplace is ensured by a removable casing where dust and sawdust accumulate. The angle of inclination of the stop is up to 45 degrees, dimensions - 785x590x550 mm.

"ZUBR MASTER" SRF-254-1600S - a popular domestic machine, the main advantage of which is ease of use. The change of operations takes place in just a couple of minutes, the belt-type transfer allows the product to last as long as possible. The electric motor has a power of 1600 W and is equipped with overload protection, which is a very useful function when the machine is used frequently. Processing through the work of two sharp cutting elements.

Like the previous model, there is an automatic material feeding system with a speed of 6 m / min. The bed is portable, the dimensions of the workpiece are up to 5 mm in thickness and 80 mm in length. The angle of inclination of the stop - up to 45 degrees, the depth of planing - 3 mm, thicknessing - up to 2 mm. The shaft rotation frequency is 9000 rpm, the machine dimensions are 1030x520x440 mm. Weight - 33.5 kg, which is slightly more than other analogs, but quite a bit for transportation and location. The delivery set includes a stand, there are no particular drawbacks.

"Ankor Corvette-26 90260" - a very versatile equipment that will be a good purchase for a home in a workshop. It can perform both planing and thicknessing, and the transition from one function to another takes a minimum amount of time. The manufacturer took care of the cleanliness of the workplace, and therefore equipped this machine with a branch pipe, at the bottom of which there is a bag, where all working waste goes.

This way, the accumulation of dust and debris will not prevent you from concentrating on the process.

The brushed motor with a power of 1500 W has high-quality and reliable protection against overheating, which will turn off the product in case of excessive use. The shaft rotation frequency is up to 8000 rpm, and its diameter is 50 mm. There are two knives, the depth of planing is up to 2 mm, the angle of inclination of the guide is up to 45 degrees. The maximum width of the workpiece is 204 mm, the thickness is up to 5 mm. The size of the planing table is 737x210 mm, weight - 28 kg. This model is good in that the work process is as simple, reliable and safe as possible, due to which this machine has good consumer reviews.

Middle class

Metabo HC 260 C WNB - versatile product with a reliable and quiet 2200 W motor. Powered by a 220 V power supply, the structure is made of high quality materials that are durable and resistant to corrosion.This machine has good components and power units, and is also equipped with an automatic workpiece feeding system at a speed of 5 m / min. The diameter of the cutter shaft is 63 mm, the cutting elements are two knives with double blades, which increases the efficiency of processing the workpiece. Chip removal - 3 mm.

The shaft rotation speed is up to 6500 rpm, the safety system includes functions to protect equipment from overloads and overheating. This model is good in that it has a reliable and high-quality assembly, and also does not require constant maintenance. The term of work is from 5 years or more, due to which the equipment can be called durable. It is convenient to operate and has a convenient design.

The machine is equipped with everything you need to process various workpieces with high efficiency.

JET JPT-10B - quite an inexpensive product among other models of the middle class. At the same time, it is technically and qualitatively not inferior to them, since this machine is equipped with everything necessary for simple and convenient operation. Motor power - 1500 W, there is a function of automatic feed of the workpiece at a speed of 6 m / min. When planing, the processing depth reaches 3 mm, when thickening, the indicator is 2 mm. Shaft rotation frequency - up to 9000 rpm, workpiece thickness - up to 150 mm.

The design is very versatile, since it can be installed both on the table and on the floor, for which a special stop is used, which is included in the package. The cutting element is represented by two knives, which are already installed and securely fastened. The angle of inclination of the stop is adjustable up to 45 degrees, the dimensions of the machine are 980x470x1120 mm, the weight is 34 kg. This model is very popular because it is easy to use and does not require any special skills from the user. In comparison with other machines, it has advantages in its assembly and arrangement.

Belmash SDR-2200 - a versatile machine, the main feature of which is high processing accuracy. At the same time, in order to achieve it, an appropriate fine adjustment is necessary, which not every user can carry out. The manufacturer made the design in such a way that the movement of the product was as convenient as possible. The working table is very wide, there are operating safety systems. Power consumption - 2200 W, shaft speed - up to 7700 rpm, cutting knives - 3, each of which is well sharpened.

Maximum workpiece width - 270 mm, thickness - up to 120 mm. Planing depth - 3 mm, machine dimensions - 985x480x496 mm, weight - 73 kg. Among the functions, it is worth noting the automatic material feed at a speed of up to 6 m / min, the rip fence is adjustable up to 45 degrees in inclination. The complete set contains a cover for removal of chips. There is also a ruler, template, pusher and other elements that simplify the use of this product.

The main advantages of this machine are high productivity and quality of manufacture of all parts of the structure.

Premium

JET JPT-410 HH Is a versatile machine often used in many large forestry and processing plants around the world. The folding planer table and adjustable stops make it possible to accommodate a workpiece with dimensions of 150x407x225 mm, which is an excellent result and allows us to call this model unusual among its main competitors. Feed speed - 7 m / min, especially powerful 4500 W motor, shaft speed - up to 5500 rpm. The angle of inclination of the planer stop is up to 45 degrees.

The total number of knives reaches 72, which gives the user the opportunity to process the product in a wide variety of options in accordance with the preset settings, of which there are many. There is an engine protection system, the maximum planing depth is up to 3.5 mm, the dimensions of the machine are 1160x920x1000 mm, the base is made of high quality reliable materials, so vibrations are minimal. Assembly weight - about 330 kg, there is an exhaust pipe, the length of which is 100 or 127 mm, depending on the adapter used.

Proma HP 410B - a premium model that performs many operations with very high precision and efficiency. Reliable construction, high quality materials and extremely long service life make this machine one of the best of its kind. Technological systems make it possible to make the use of the most convenient and automated, while not excluding fine user adjustment. Engine power - 4000 W, which together with a shaft speed of 4200 rpm allows you to process a lot of material in the highest quality.

The maximum depth of planing both in the thicknessing tool and in the planing is 5 mm. The size of the working table is 1809x510 mm, the cutting part consists of three especially sharp double-sided knives, the operation of the machine is carried out through a network with a voltage of 380 V, which corresponds to the production capacity. The body is made of durable cast iron, the tilt of the guide bar is up to 45 degrees, a high-precision ruler is built-in. A special outlet is provided for removing shavings, the dimensions of the machine are 1900x850x1100 mm, the weight is 377 kg.

Robland NXSD 310 - unusual equipment, which mainly works with long workpieces of small and medium size, which differs from its counterparts in terms of price range. The engine also has less power - 3750 W, shaft speed - up to 5500 rpm. Only 3 knives, voltage used - 380 V, feed speed - up to 6 m / min. The size of the working table is 430x310 mm, the depth of planing in both modes is up to 4 mm. One of the advantages of this machine is its simple design.

The dimensions of the model are 1585x750x1010 mm, the maximum angle of inclination of the stop is 45 degrees, the entire control system consists of two buttons, so operation cannot be called overly complicated, because the main preparation of the product consists in adjustment. Robland NXSD 310 is good because it works quickly and at the same time with high quality, therefore it is designed in such a way as to handle small workpieces. Weight - 280 kg, there is an engine protection, a cutterblock guard is provided.

Criterias of choice

Before choosing a planer-thicknessing machine, refer to some recommendations that will help you not to make a mistake before buying. First of all, pay attention to the reliability of the design and materials of manufacture. They must be of appropriate quality, no backlash or swaying of the machine elements are allowed.

The fixation is tight, everything is configured accurately and as accurately as possible - these are the requirements for good equipment.

Also, when selecting, do not forget about the characteristics, among which the most important are the engine power, the depth of processing of the workpiece, as well as the shaft rotation frequency.

The instructions for the machine must be understandable so that in case of misunderstanding on the part of the user, he can turn to a reliable source of information.

When it comes to models, don't always rely on the brand alone. This might make sense when buying professional equipment from a company that has proven itself to be reliable and truly high quality. The low-cost segment, for example, has many good representatives from not the most famous companies, but this does not make the equipment worse.

The comment was sent successfully.