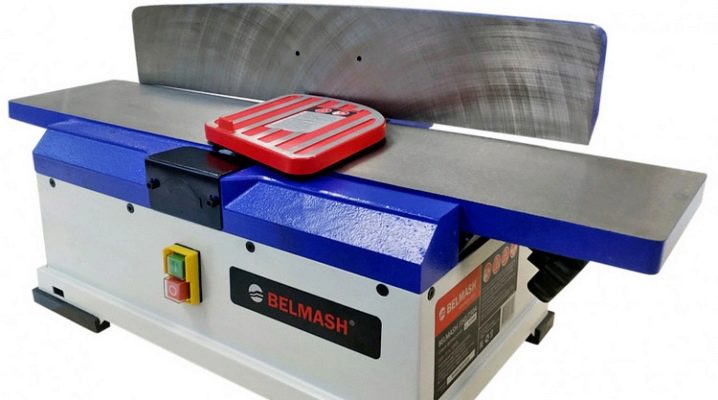

Jointing machines BELMASH

Belmash planing machines deserve at least attention from consumers. It is necessary to carefully study the characteristics of planing models and devices with a thicknessing tool for wood. It is also worth familiarizing yourself with the reviews of similar devices.

Advantages and disadvantages

The modern planer is an excellent helper in a wide variety of applications. The thickness of the processed material can be varied. Usually, on planers, workpieces with a length of at least 1 and no more than 1.5 m are used. Too short workpieces are traumatic. Too long create inconvenience when fastening, tend to deform and are not cut accurately enough.

With the help of a planer, you can prepare a piece of wood for subsequent highly precise processing. The cost of such equipment is low. It is suitable for manipulating furniture products.

He has no particular disadvantages. However, it is necessary to correctly understand the features of each device and its capabilities in order to avoid mistakes.

Range

For woodworking, the J300 / 2100BMH might work well. It is designed for a mains voltage of 380 V. The device is equipped with a Helical shaft. With a total power of the asynchronous drive of 2.88 kW, a power of 2.2 kW is delivered to the shaft. At idle speed, the shaft rotates at a speed of 5000 turns per minute.

The width of the planed strip reaches 30.5 cm. Angles can be varied from -45 to 45 degrees. 96 quality knives are connected to the shaft. The work table is made of cast iron. The parallel emphasis is also made cast iron.

The J150 / 730A can be considered an alternative. This machine has a total power of 1.25 kW, while on the shaft it is only 0.735 kW. An important advantage that justifies such relatively low rates is the power supply from the household electrical network. The cutting shaft is equipped with straight knives; it can rotate at a speed of 10,000 turns per minute. The device is compact, made in a desktop form.

Cast iron is used for the manufacture of work tables and a parallel stop. The base of this machine is made of aluminum. A special scale helps to precisely adjust the working depth. A system for removing chips and dust is provided, supplemented by a bag of 70 liters. Safety during work is ensured by a protective cover.

There is also a planer-thicknessing machine in the assortment of Belmash, or rather, several of these models. As a sample, it is appropriate to disassemble JT-2 410 / 225S-380. This device is equipped with a Helical shaft. With a total power of 4 kW, 3 kW is delivered to the shaft. To operate the machine, the mains voltage is 400 V at a current frequency of 50 Hz.

The width of the strip to be processed is 41 cm. This is not a bad indicator for both conventional planers and thickness planers. Heavy cast iron components and significant total weight allow for a confident, vibration-free operation. The speed is sufficient for a clean cut; the parallel stop allows you to plan at the end or at an angle.

Review overview

Belmash planers work very well. The overheating protection system operates only in the most demanding operating conditions. Such equipment fully justifies its cost. Overall, it is reliable and stable, even under the most challenging operating conditions. At the same time, the dimensions of a number of models are suitable for transportation in a passenger car.

But sometimes there are complaints:

- in some models, the handle that adjusts the size is not fixed (and vibration constantly resets it);

- without connecting a chip extractor, the use of jointers and thickness planes is impossible;

- rulers are sometimes not fine-tuned;

- when using models with low power drives, only soft woods can be processed.

For an overview of the J200 / 1900 ARH machine see below.

The comment was sent successfully.