Features of cutting machines

Among the many types of production machines, cut-off counterparts occupy an important place. They are extremely popular in procurement areas of production, where the bulk of the work is related to simple material processing. And also the cutting equipment is very wide in its species diversity and functionality.

general description

This type of machine can be attributed to one of the most frequently used in industries of all levels. Cut-off counterparts are used both at small enterprises for the procurement of raw materials, and on a large factory scale, where a constant large flow of products from stone, wood, metal and other materials of manufacture is established. Before buying such a unit, the consumer has the opportunity to choose both in terms of individual parameters and functionality, and in terms of the way of work. The most popular of them is abrasive, which is used for cutting off rolled metal products of various shapes.

Among other variations of operation, it is worth highlighting the bottom, frontal and pendulum feeds. It should be said that they carry out their work in different ways and approach specific forms of blanks. The main cutting elements of this type of machine are reliable and fast metal saws or discs of different diameters.

The simplicity of the design of the working mechanism makes the cutting machines extremely cost-effective and easy to maintain.... It also has a positive effect on the efficiency and productivity of the equipment.

There are many advantages to cutting machines... The first of these is the high degree of safety and reliability achieved through a clear design. Due to this, even an inexperienced worker can use the machine. Adjustment, start-up, service, and other stages of preparation and operation are simple in their execution. Another equally important plus is the ability to connect a chip suction device, which will keep the workplace clean.

As for small-sized products, they are often equipped with transport wheels, which increase the mobility of the unit. As a rule, this advantage is typical for machines with a wide range of functions. In products from well-known manufacturers, you can find the possibility of choosing a complete set and installing individual modules that can make the work more varied in accordance with the dimensions of the workpiece, its shape and an increase in the number of cutting methods. Some professional models are equipped with additional nodes that increase the number of simultaneous operations.

Extended functionality is also useful in that it allows the cutting machine to perform part of the functionality inherent in other types of products... Therefore, in the case of purchasing such a unit, you can save both on equipment and on subsequent service. Cutting machines perform three types of operations, the first of which is the cutting of a tube of profile and round sections. To carry out such work, large units are often used that support wide pipe diameters.

The second operation is cutting and processing strips and corners... This variation of operation is simpler and requires only the basic mechanisms available in all machines, regardless of their cost and configuration. The third type of operation is various sheet metal cutting operations.

It is important to note that cutting machines can also be used for processing plastic and wood products, if this is provided by the installed cutting attachments.

Views

Among all types of cutting machines, you can see a wide classification depending on the specific qualities of the units. One of the simplest typical classifications is to indicate the way of work.

Disk

This is the most popular type of cutting machine with many advantages. The first of these is an extremely efficient device, which is represented by a fixed disc with a certain rotational speed. At the moment, most of these machines are equipped with work units made of high quality materials, which makes it possible for the user to worry less about service and periodic adjustments. Disc cut-off models are distinguished by the possibility of variable modification.

Some manufacturers custom-build basic machine tools and then offer customers a full range of enhancements to choose from. Thus, the consumer can choose only those technologies that will be necessary for him to achieve production goals.

Another plus is to be called versatility, because the disc cutting equipment is very variable and can perform many operations with various workpieces. Such equipment is used by large enterprises where high efficiency and an appropriate level of productivity are important requirements. Of course, cost can be distinguished among the disadvantages, but due to the characteristics of this type of machine, the price is fully justified and can pay off in a fairly short time.

Hacksaw

This is another equally popular type of cutting machine. It should be said that this type of equipment has a wide consumer base due to the peculiarities of its functioning.

The main way of working is the action of a hacksaw blade fixed to the saw frame. That is, in this case, the main unit performs its function in a pushing way, smoothly cutting off the rolled metal in designated places.

Another advantage of hacksaws is their compactness... Due to the simplicity of the design and its reliability, manufacturers of such equipment were able to achieve small dimensions so that the equipment could be operated without any inconvenience.

According to the type of work, hacksaw cutting machines are classified into automatic and manual... The former are driven by an installed engine of a certain power. Thus, the operator only sets the course of the machine and ensures the correct movement of the workpiece throughout the entire operation. The rest is done by the work units and the automation system. Manual counterparts are cheaper and simpler in their configuration, but are not intended for large industries. Among the minuses, one can note the requirement for constant provision of the workflow on the part of the user.

And also manual hacksaw machines are not able to issue high productivity, and for this reason they are not used in constant mass production.

But due to their cheapness and simplicity, they are popular options for small private workshops, where it is necessary to cut the workpieces only periodically in small quantities.

Bandsaws

The basis of the application of this type of machine is a high-speed steel saw, which has a number of positive properties.... First of all, the operator does not need to perform many actions in order to reliably operate the equipment. Everything happens automatically. The second plus is to highlight the rather low probability of material loss. That is, the amount of flying out chips is extremely small, which makes it easier to keep the workplace clean.Belt models are very productive, and therefore are in demand among large enterprises, where serial production of blanks of various characteristics has been established. It should be said about the wide range of these products among the leading manufacturers.

Popular manufacturers

For a long time, the use of cutting machines in the modern market has appeared many manufacturers, whose products can be safely recommended to the buyer.

It's worth starting with a Turkish company KESMAK, popular in Europe and gradually establishing sales in Russia. This company specializes in various types of band saws - semi- and automatic, as well as pendulum and double-column. The manufacturer variably approaches the process of making new models, for this reason, he tries to constantly supplement the configuration and expand the functionality of the equipment.

It should be noted that KESMAK machines are focused only on the processing of rolled metal, and therefore are most often used at enterprises for the manufacture of products from such material.

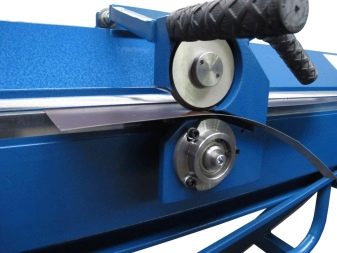

The manufacturer decided to make the design of the machines the most reliable and at the same time compact, trying to save space where it could be done. All models are equipped with mechanical rulers that allow you to determine the angle of rotation of the saw frame. Built-in hydraulic vise, handwheels made of durable cast iron. To improve the quality of the cut and reduce the level of vibration, KESMAK has equipped its products with a movable support system that moves along linear guides. They, in turn, are made of carbide materials and have an increased working life.

Another well-known manufacturer is an American company JET... It has a particularly wide assortment of various types of machine tools, among which there are cut-off machines. Among them are band saws for wood and disc for metalworking. The peculiarities of the machines of this manufacturer is a variable approach to the formation of the complete set. Some models are made in several versions, where the technical characteristics and part of the equipment are subject to major changes. Special attention was paid to disc products that belong to professional equipment.

First of all, these units have a reliable solid base, which successfully fulfills the role of not only the basis of the structure, but also a vibration damper. To prevent chips from accumulating during operation, a special garbage compartment is provided. And also JET equips products with a high-quality cooling system by bringing the lubricant directly to the surface of the disc and other most active tools, thereby reducing the load on them. Thanks to this, the working life of all main units is noticeably increased. The manufacturer also carefully approached the issue of safety, and therefore built a number of technologies into its cutting machine tools to protect the engine from surges in the power grid.

Another well-known manufacturer of cut-off products is the company Makita... In its assortment there are assembly units for metal. Among the main advantages, it is worth highlighting the simplicity of the design, which gives the user the ability to fully control the workflow. The company decided to focus on the small size of the units, so they all turned out to be desktop based on the type of arrangement. Sufficient motor power allows you to cut workpieces of standard thickness.

The average cutting depth among all models is 110-120 mm. Such products are popular for small private workshops not only because of their small size and simplicity, but also due to the affordable price, which is clearly lower in comparison with full-fledged automatic machines. Makita is renowned for its quality, which translates into ergonomics and ease of use.The package may include various accessories, but this is individual and depends on the specific model. Among the functions used, it is possible to note the ability to rotate the blade by 45 degrees, which allows them to be used for slitting.

Selection Tips

To choose the right cutting machine, you must adhere to a number of criteria. The first of them is the most important and includes the definition of the scope of work operations that will be carried out by the equipment. This applies to both the processing material and the shape of the workpieces. For example, if a potential buyer is going to cut large pipes along the cross-section, then he will need more overall powerful products, but if there is a need to separate small metal strips, then he can do with a standard small machine.

It is important to understand what kind of performance the consumer needs... In one case, we can talk about a frequent and periodically continuous process, in other situations, machines can be used quite rarely to carry out only a few operations. By this criterion, you can choose the type of work - automatic or manual. And also pay attention to the design, its reliability and workmanship. On good machines, this part is always made in accordance with all technical requirements.

Consider other parts of the equipment as well - work units, swivel heads, measuring instruments, guides. There should be no backlash. If you have already decided on a suitable range of models, then it is worth referring to the reviews and documentation for a comparison of features and available functions.

Do not forget about the items that come with the purchase.

Nuances of operation

Despite the relatively safe design of cutting machines, during their operation, you must carefully monitor the working process.... For this, the documentation contains a specific list of rules and indices that determine the correct operation. It should be understood that processing a large number of workpieces has its own nuances. The first is the cut-off chip. Some manufacturers' products have compartments for collecting waste for this, and chip suckers may also be available.

If the complete set provides for protective partitions or covers, then they must be installed in accordance with the instructions. Always observe safety precautions when working with the machine, especially if it involves the direct participation of the operator in the process.

Do not forget to periodically inspect the equipment and carry out diagnostics, if necessary, replace cutting parts and other consumables. If a serious breakdown has occurred, then it is better to contact a specialist than to try to fix the problem yourself.

Always remember the basic conditions required for the operation of complex equipment.... The room must be clean and dry and the worker must wear protective clothing. Try to organize a stable network connection. A cut-off machine is a piece of equipment that is best not to save money on if you need a quality tool.

The comment was sent successfully.