All about gang saws

After reading the article, you will be able to find out everything about gang saws. Readers will receive the necessary information about disk machines for wood and frame samples, about two-shaft and other types. Shark 2M and a number of other models will be characterized.

Peculiarities

The name of the gang saw itself refers to woodworking equipment that is used to process boards and to manipulate logs. Technically, this is a variation of a circular saw. Instead of one circular saw, a whole group is used. Such saws are sometimes placed not on one, but on two shafts.

The multi-rip design of the machine, along with the advantages, also creates some problems - for example, it is rather difficult to ensure chip removal.

The multi-blade design still remains limited in the height of the processed materials. The addition of the second shaft is intended to mitigate this limitation. But on the other hand, several tens of cubic meters of sawdust are formed during a work shift. Their removal should be thought out by the designers. And they are also obliged to provide for the elimination of scraps of the wane part of the timber.

Modern gang saws are extremely reliable and cost effective. They are relatively easy to use. The performance of such equipment is several times higher than that of other devices. The cutting of the tree in the longitudinal plane is carried out extremely accurately. Performance is also ensured, and almost all models have a good level of automation.

Some of the samples are designed with the expectation of mechanical feed of workpieces. No other sawmill can provide such precise work. In terms of cost, the equipment is more attractive than a band saw machine. Workpiece cutting speed and cutting depth vary widely. The dimensions, weight and power of the equipment can also vary significantly.

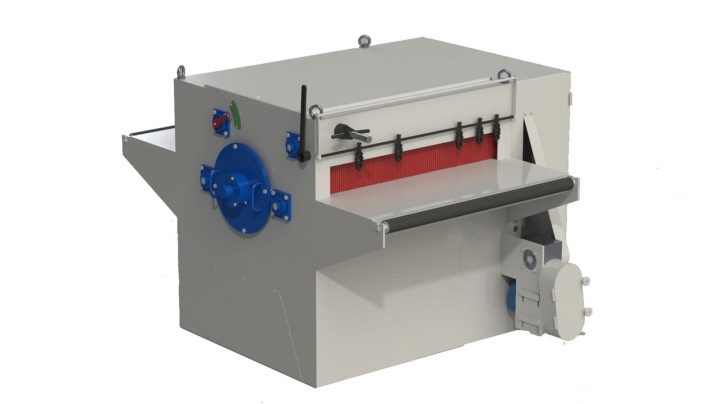

The bed is the key part of the machine. It performs not only a supporting function. It is inside it that the main working parts are located. Thanks to the motor, the cutting parts move. They are capable of both spinning and moving back and forth.

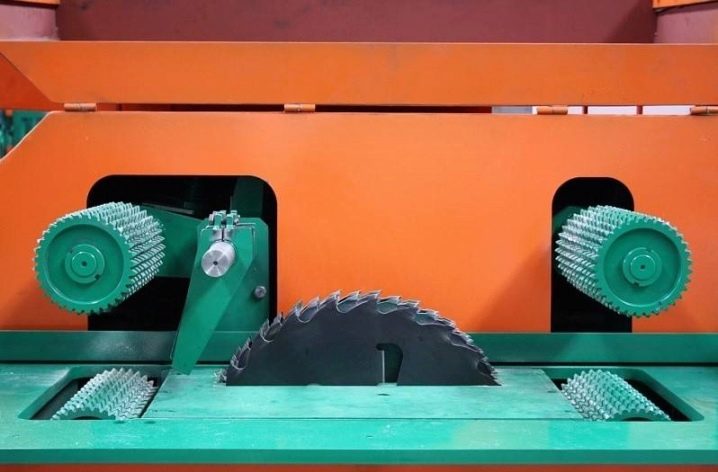

The movement of the feeding segment also depends on the engine. Cutting is done with saw blades attached to the shafts. The feeding system is important. Large workpieces can only be moved by a serious feeder. Basically, a combination of 4 feed shafts and 2 feed shafts is used.

The hole for the movement of workpieces is equipped with a so-called claw system. It prevents sawn timber from flying outward, which could harm the people working on the machine. The exit is also equipped with an insulating curtain. Chip extractors can be connected on request.

Wooden pieces are fed horizontally. They are firmly clamped with rollers, thoroughly fixing from above and below. The feed takes place at a speed of 30 to 70 m / min. There is no need for a reinforced foundation.

Decent characteristics of gang saws make them more and more popular every year.

Species overview

Framed

Such devices are designed for sawing a bar into several boards. The technical principle of operation is quite close to that of a simple sawmill. The cutting device stretched inside the frame (circular saw unit) is just the main working link. The main functional movement takes place thanks to the crank assembly. The systems are designed for sawing double edged beams and unedged boards.

Disk

Such systems are suitable for particularly high-quality sawing of cant. With their help, you can make special edged blanks. The accuracy of product manufacturing rises to the maximum. This technique can even cope with frozen wood. This circumstance makes it possible to confidently work in the north of Russia, in Siberia and the Far East. This kind of technology got its name for equipping with circular saws.

Canting

Such a device works with large logs. They are cut lengthwise. Good quality equipment works well with both coniferous and deciduous wood. Setting up twin-shaft machines for each specific task is done quickly and accurately. The manual type of multi-saw machines stands apart.

It is also called mini-machines. Such devices are readily purchased for home use. They are also in demand in small professional workshops. Small size and low power consumption justify the limited functionality.

This technique works very simply and does not create problems for the owners.

Popular models

It makes sense to start the review with version "Shark 2M"... This apparatus has an electrical power of 37 kW for each of the shafts. The designers were able to solve the problem of sawing two-edged and three-edged cants. Its maximum height is 21 cm. As a result, a good edged product is obtained. In favor of the "Shark" is evidenced by a weighty reliable case made of 1.6 cm thick sheets of metal.

Together with rolled metal, it will prevent vibrations during sawing work. The service life of this model is quite long. The cross section of each of the shafts is 7.5 cm. Both of them are equipped with keyways. In total, it is allowed to put up to ten saws on each shaft.

An important part of the job is to define the gap that separates the sawing parts. This is achieved using spacer sleeves. The designers have provided for the possibility of sawing on one lower shaft separately. In this case, the height of the boards produced will be, depending on the section of the saw, 11-16 cm maximum. It is possible to equip the machine with more powerful drives - 40 and even 55 kW.

Other Notable Traits:

-

the gap between the extreme saws in a row is 70 cm;

-

smooth stroke adjustment due to the frequency converter;

-

mode of smooth start of the motor;

-

adding an ammeter to the design;

-

enhanced claw protection;

-

acceleration of the adjustment process;

-

machine clearance 75 cm;

-

torsion of the shaft at a speed of up to 3000 rpm;

-

the maximum permissible processing rate is 18.5 m / min;

-

required voltage 380 V;

-

device weight 2900 kg;

-

circular saws must be purchased separately (not included in the shipment).

When choosing a single-shaft multi-saw machine, it is worth taking a closer look at model "Altai-KS-1000".

This is an edging equipment that allows you to obtain, along with an edged board:

-

bar;

-

rail;

-

three-edged croaker.

Suppliers insist on full compliance with all safety standards. Adjusting the gap between the saws can be done quickly and reliably. The processed lumber will have the most accurate geometry. Important technical points:

-

cut up to 10 cm high;

-

saw section from 25 to 35 cm;

-

screw adjustment of the thickness of the boards;

-

gap between extreme saws 94 cm;

-

feed drive with a power of 1.1 kW;

-

saw unit motor with power from 22 to 55 kW.

Another multi-rip edge trimmer is ISS-1000... It differs in cutting heights up to 12 cm. The device is declared as suitable for sawmills of medium and large capacity. Equipped with long shaft and extended feed table. The productivity is high enough for the MKS-1000 to become in the second row of woodworking, after the R63 sawmill and its analogues.

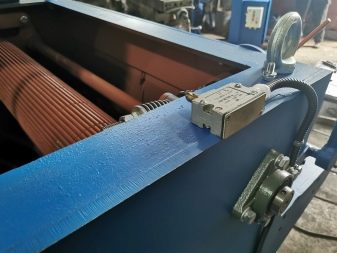

Double-row claw protection at the entrance is carried out strictly in accordance with GOST. It guarantees almost complete safety when used correctly.In reverse mode, the claw guard rises. The ammeter helps to accurately control the load on the drive and indirectly detect the loss of sharpness on the saws.

Sawing is made easier with laser pointers.

Components

The most important part for gang saws is predictably the saws. They do an excellent job with their tasks, but they periodically fail and must then be replaced. Spacer rings are also relevant. They allow you to adjust the cutting height. And also it is worth mentioning the felling units - the very ones on which the discs are placed.

Rows of disc elements can be placed either vertically or horizontally. The choice between these solutions is due to engineering considerations. The bed is sometimes performed as a feed line. It is equipped with casters for easy transport. The ADF is a block of studded shafts; it moves the workpieces evenly throughout the sawing space.

Other important components will be:

-

steel rivets;

-

screws;

-

brackets;

-

feed wings;

-

crankshafts;

-

hazelnuts;

-

torque wrenches;

-

pneumatic cylinders;

-

tumblers;

-

collet fittings;

-

connecting rods;

-

driven pulleys;

-

electrical cabinets.

Selection Tips

A very important point is the largest quantities of processed raw materials. Multi-blade machines with two shafts are more advantageous in this respect than single-shaft systems. If you have to process lumber or a double edged beam with a uniform width, then machines with a rigid installation are suitable. But in most cases, this solution is impractical because it makes reconfiguration very difficult. A flexible set in combination with a single shaft will be the optimal solution for edging unedged boards.

However, the downside will be the complication of work and the rise in the cost of the product itself.

Operating rules

Even the best gang saw is important to use carefully. The feed pieces must always be geometrically correct in relation to the workpiece. It is necessary to process only the type of wood that is provided by the designers of a particular apparatus. Responsible operation also means:

-

tracking the degree of wear and dullness of circular saws;

-

exclusion of equipment overload;

-

strict observance of the instructions of the instruction;

-

regular diagnostics for the prevention of deformities and disorders;

-

cleaning from dust and shavings after the end of each work session;

-

systematic replacement of lubricants and the most wearing parts.

The comment was sent successfully.