JET bandsaws

The processing of wood and metal is a very laborious process in which the right tool plays an important role. This can be called band saw machines, which are widely used in everyday life and in production. Among the leading manufacturers of this equipment, it is worth highlighting the products of the JET company.

Peculiarities

Before buying equipment, the user has many questions about what criteria must be adhered to at the time of choice. It is worth saying that, first of all, the consumer pays his attention to the features of the machines, their advantages and disadvantages.

JET bandsaw machines are distinguished by the fact that they are presented in a wide variety of variations. The firm offers customers products in several price ranges, so people have a choice in accordance with their budget. It is worth highlighting the JET production process, which is at a very high level.

When creating its products, the company uses only high-quality materials that guarantee a good result of the equipment.

The manufacturer's band saws are presented in several types. There is a division depending on the material being processed - wood or metal. And also JET manufactures both purely professional and semi-professional and amateur desktop equipment. If the first is used only in conditions of large and complex production, then the other two types of products can be used in everyday life or in a small workshop, where the volume of production is not one of the key indicators.

JET bandsaws are also suitable for those who see machining more as a hobby than a permanent job.

The manufacturer pays special attention to the entire structure as a whole, and not to individual components, while not forgetting to equip the range with all the necessary technologies and functions that make operation easier and more convenient.

Assortment of models for metal

JET MBS-708CSB - one of the inexpensive models, which is very popular with consumers due to good equipment and technical characteristics. This band saw machine works in manual mode, and can also be operated in a cycle when sawing. The saw frame is raised manually while the rest of the workflow is automated until the blade is turned off. To make the result of use more effective, the adjustment mechanism is made most smoothly, thereby making it possible to select the optimal cutting mode for workpieces.

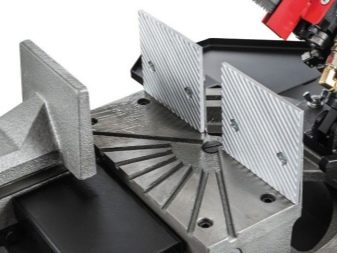

The strain gauge is used to determine the degree of web tension, which is carried out manually. The saw frame can be rotated 60 degrees, which significantly increases the variability of the process depending on the user's skill. And also it is convenient in the manufacture of metal structures of various types. Thanks to 5 bearings, the guides do not emit excessive vibrations and do not cause the web to slip. Coolant is supplied to the working mechanisms and the workpiece, which ensures the high efficiency of the machine. The complete set includes a brush for cleaning equipment from coarse shavings.

The blade rotation speed can be adjusted in several positions. Angle cutting from 45 to 60 degrees. The maximum turning diameter at 90 degrees is 180 mm. The web speed ranges from 35 to 85 m / min. A 750 W motor is installed. The volume of the coolant tank is 10 liters.The dimensions of the machine are 1140x562x1295 mm, the width of the band is 20 mm. Weight 116 kg.

JET MBS-1113DASP - a professional band saw designed for industrial use. The main area of application is the creation of solid sections and various profiles. The saw frame is pivot-type with a deviation of 45 degrees to the left and 60 degrees to the right, which increases the variability of the work process. The maximum diameter of the workpiece when sawing at 90 degrees is 270 mm, when turning - 240 and 210 mm, depending on the side of the slope. The saw frame moves according to a program that is set via the console panel. This makes the process more automated and accurate.

The built-in hydraulic system allows the vise to be used to hold the metal tightly without the possibility of movement during processing. The driving base of the machine is a 1500 W electric motor, which, due to the gearbox, sets in motion all the necessary mechanisms of the product. There is a frequency converter, the main function of which is to change the material feed rate from 20 to 85 m / min. The control of the machine is made in such a way that the user, after starting the equipment, only monitors the technological processes. The remote control with all the important indicators and values will help him in this.

The stable stand and bearings of the saw frame ensure reliable operation of the machine without slipping the blade when working with large workpieces. It is worth noting the coolant supply system, due to which the operating life of the equipment lasts as long as possible, and the use of the machine becomes more efficient. A rotating brush cord is provided so that chips and other industrial debris does not have to be removed manually. The height of the density of the vise is 860 mm, the dimensions of the band blade are 27x0.9x3160 mm, and its width reaches 27 mm. The dimensions of the JET MBS-1113DASP are 1885x690x1540 mm, the weight is 530 kg.

Woodworking machines

JET JWBS-10S - a popular woodworking machine, which consumers liked due to its affordable price, convenient design and variability of work with blanks. The saw blade has two speeds, the blade is equipped with two guides, which increases the accuracy of the equipment. The work table is made of cast iron, renowned for its durability and reliability. It is this material that is used to create a wide variety of machines - professional and amateur, and regardless of their type of work or size. And also the table is suitable for placing large workpieces with a height of 152 mm, which is not found in all models of this or lower cost.

The rip fence has eccentric clamps that have proven themselves to be reliable in woodworking machines. And there is also an angle stop with its own guide.

For floor installation, a set of support legs is provided, there is an adjustment of the cutting height by rotating the handle. A millimeter scale is located next to the guide profile to ensure that the machining is as close as possible to the user's requirements. Among some variations, it is worth noting the ability to connect various ventilation pipes to keep the workplace clean.

Motor with a power of 450 W, blade speed 400 and 800 m / min, and its length is 1826 mm. The diameter of the pulleys is 252 mm, the angle of inclination of the working table is up to 45 degrees, thereby making it possible to process wood in several variations. The maximum workpiece width is up to 245 mm, the working table has dimensions of 360x320 mm, the diameter of the exhaust connection is 50, 75 and 100 mm. Machine dimensions 700x560x1650 mm, weight only 38 kg. Separately, it should be noted that a considerable part of the JET JWBS-10S mechanisms are adjustable, so this machine is capable of performing complex tasks with the correct parameters.

It is this feature that attracts users, because due to their skills, processing becomes very variable.

JET JWBS-14Q - professional equipment, the main difference of which is the design and technological set of devices. The base is a rigid frame and a massive structure, due to which even the most intensive work over a long time will not be able to negatively affect the processing result. The choice of saw blades is very diverse - from 3 to 25 mm. This allows the machine to be adapted for both radial and straight-line operation. The maximum allowable workpiece height is up to 200 mm, there is an eccentric parallel stop lock. The web speed is only one and is 800 m / min.

The engine has a power of 1000 W, the diameter of the pulleys is 355 mm, the cast iron working table is 385x500 mm, the diameter of the exhaust connection is 100 mm. The length of the saw blade is 2560 mm, the angle of inclination of the working table is from -10 to 45 degrees, the maximum width of the workpiece is 350 mm. Machine dimensions 650x770x1800 mm, weight 97 kg. Of course, the design of this model is more difficult to transport, and it is less mobile in comparison with other sawing equipment, but the improved characteristics and the possibility of various adjustments make it possible to have a good volume of processed workpieces. It is also worth noting that when creating JET JWBS-14Q, the manufacturer focused on power and quantitative operation, so the machine can work for a long time and without interruptions, which cannot be said about cheaper analogues.

The comment was sent successfully.