Varieties and operation of edging machines

Knowledge of the varieties and features of the operation of edging machines is very important for the organization of woodworking production. There is a two-saw machine for wood, a multi-saw and a single-saw, but that's not all. Additionally, you have to take into account manual and automatic samples, models of the continuous type and other types.

general description

For woodworking, a large number of different devices have been created, each of which has its own functions. Edge-trimming machines, as their name implies, trim the edges longitudinally.

Most often, such a need arises when receiving edged boards. Such equipment is valuable both in general woodworking and in furniture production. It finds application in medium and even large enterprises; in small shops and workshops, edge processing is carried out only sporadically.

The edge trimmer still plays a major role in the furniture industry. There it has long been considered an indispensable device. Thanks to this technique, the assortment of lumber increases, and you can not throw out the defective boards, but refine them. As a result, the yield of useful products increases. Its main types:

-

lining;

-

blanks for pallets;

-

slab rail.

Those who know woodworking firsthand have a good idea of how much waste is generated there. A high-quality edging machine will easily dissolve them on boards with a width of 0.5 cm or more. As a result, production will approach a zero-waste level. This technique is versatile and has decent performance.

It can also be operated for a long time and is relatively simple, which is important in case of insufficient qualifications of workers.

Species overview

By the way the engine is powered

The most common and convenient are electrical devices. They are easy to use in almost any large settlement. But if the production is located in hard-to-reach places, liquid-fuel models are more attractive. The economic feasibility of this or that option plays a decisive role in the choice. However, security, redundancy and other considerations are also taken into account; sometimes it is easier to buy a certain type of machine and build the infrastructure for it.

By the number of drank

The simplest solution is a single saw. The device is only capable of doing one run. Then the lumber has to be turned over independently in order to continue working. The two-saw machine is more complicated. In one go, he will finish the board properly on both sides. A multi-rip edge trimmer has, as the name suggests, several saws - and therefore it is not difficult for it to produce the required workpieces without additional processing.

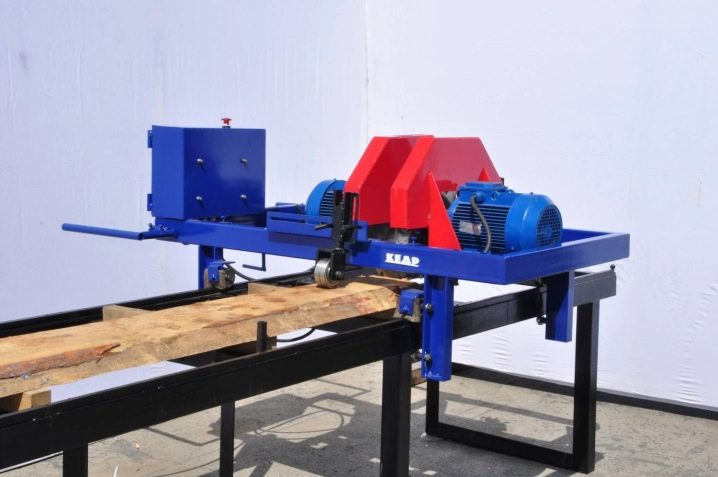

Almost all two-saw equipment has a through-type design. Thanks to this solution, the efficiency of processing unedged boards increases significantly. Typically, these systems operate with the supply of virgin lumber along special guiding elements.

It is also important to consider the dependence of the machine on the worker. Now they can offer both manual and automatic devices; the second option is predictably more expensive.

The best manufacturers and models

It makes sense to start the review with the OB-II model. Such a device is suitable for longitudinal trimming and cutting of unedged boards. The thickness of the processed wood reaches 8 cm.In most cases, OB-II is bought as a “second row machine”. The cutting speed has been increased. The spacing between the saws is automatically adjusted, you can also control the kerf width manually, if required.

Individual trimming of boards with different widths is allowed. The saw blades are easy to change (this takes no more than 3 minutes). The designers have provided for the possibility of adding 1 or 2 laser pointers. Technological parameters:

-

processing width - from 7 to 42.5 cm;

-

processing height - up to 8 cm;

-

saw section - 40 cm;

-

6 steps of speed feed;

-

power of each of the 2 saw motors - 4.5 kW;

-

total power of all engines - 11.5 kW;

-

linear dimensions (excluding tables) - 150x150x140 cm;

-

total weight - 1400 kg.

BAS 2-7.5-15 can be considered as an alternative. With this edger, you can turn a slab into an edged board in one pass. In this case, the feed rate reaches 30 m in 60 seconds. The conclusion is simple: such equipment is suitable for very productive industrial lines. The width of the cut edges is electronically adjustable and the feed rate is infinitely variable.

The saw shafts are braked by a specially added electronic component. The working table is elongated. The saws are set automatically in width; 6 standard sizes are provided. The machine has a pair of feed chains, which makes it as efficient as possible. A first-class edged board is produced with fairly accurate dimensions.

The distance rings help control the height of the saw and riving knife. The right saw is rigidly fixed, and the left can be shifted according to the width of the material. The clamping unit works very reliably and allows the slab to be fed stably. The pressure rollers are equipped with gas stops. The speed of movement of lumber can be up to 0.5 m in 1 second; a typical configuration includes a feed table 450 cm long and 40 cm wide.

To remove sawdust, a pair of aspiration channels is provided: above and below. Thanks to the claw guard, operators do not have to worry about the ejection of the slab. The length of the material is from 200 to 400 cm. The smallest working speed is 10 m / min. The machine weighs 1500 kg.

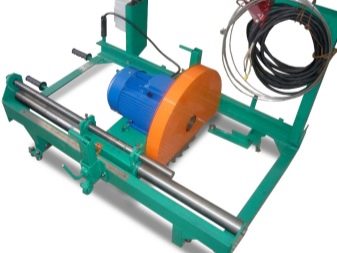

The DKO-55 also deserves attention. This machine is claimed to be able to guarantee the maximum yield of edged lumber. It is widely used in power sawing, including when reworking the slab. Sometimes it is allowed to operate on sorting lines to improve the quality of wane boards. For an 8-hour work shift, the machine will produce up to 72 m3 of finished product.

The system works according to the pass-through scheme. Feeding is carried out by means of rollers. Adjustment of the saw is possible thanks to the turret. The fixed area can be equipped with 1-3 fixed set saws. There is no direct need for a well-equipped base, the device works stably on a flat concrete surface.

Among other manufacturers, noteworthy:

-

Krafter;

-

Data center;

-

PAUL KME.

Features of work

Before starting, the discs must be so that they spin freely. Caps and other parts should be closed as carefully as possible. Do not use edge trimming equipment without activating suction and without gloves or other protective equipment. You can work with boards and slabs with confidence, but you won't be able to cut logs. All components of the device must be lubricated and adjusted before starting it.

Any unforeseen situation requires the use of an emergency switch. After the situation has returned to normal, it is returned to its normal position. The procedure for replacing saws and discs is prescribed in the instructions. The stops are set in accordance with the length of the boards to be processed. After removing the sawn-off material, the remainder of it is shifted properly.

The comment was sent successfully.