What are CNC machines and how to choose them?

CNC machines are the main tool for mass machining of parts. It is an important component of computer-aided design systems. The principle of creating a CNC is to simplify the production of parts of the same type.

What it is?

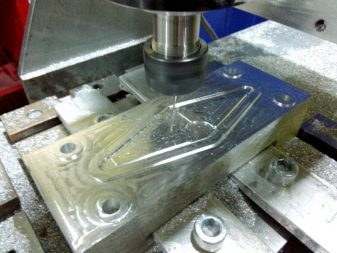

CNC machine - a device with numerical control. Its main feature is easy copying of similar and single-type parts: a program-image recorded in the read-only memory, according to which parts are milled and sawn from workpieces placed in the working area using the conveyor feed mechanism. The machines equipped with a laser-plasma gun, which perform perfectly smooth cutting of primary and secondary workpieces, are characterized by high throughput. Slightly lower in terms of technological equipment are turning and milling machines that carry out non-laser (with the help of cutters) turning, sawing and reaming (drilling) of workpieces.

The supply of the laser beam to specific cutting lines (or cutters, drills, discs, etc.) is controlled not by the operator, but by the software module. Decoding "CNC" literally means numerical control. The human factor here is reduced only to the input of the initial parameters.

In modern CNC machines, there is no need to connect an external PC or laptop - the role of a preliminary (operator-controlled) programmer that sets the parameters is played by an on-board microcomputer installed in a machine compartment protected from electrical noise. Modern CNC machines can also be connected to a local server network (LSS) via a LAN interface and controlled from any PC on the territory of the enterprise, which is allowed access to this machine by the network administrator, as it has been working for 20 years, for example, with network printers and scanners.

The structure of the CNC machine is such that the technical (electromechanical) part is rigidly connected to the electronic (ECU) and at the same time is separated from it, separated from it in the limited internal space of the unit... One of the design features of the CNC unit is the shielding (protection) of the ECU from interference generated by electromechanical circuits in the working area and the operating mode switching area. This interference can "knock down" the program, therefore, the on-board single-board PC is not only removed from the electromechanics (motors, sensors), but also placed in a protected steel box, which is reliably grounded and will almost completely eliminate static and noise from entering the CPU and other vital electronic organs. control of the CNC unit.

Views

The advantage of a mini home machine is that it is a worthy solution for young professionals who have begun to master the basics of working as a CNC machine operator... CNC machines are classified according to the list of operations performed and according to the characteristics of the control system. Despite the first and deceptive impression of a beginner that this "monster" is too difficult, mastering the basic techniques of work can take from half an hour to several hours. A beginner can quickly compose his first algorithm for processing parts, the production process of which he is interested in. For example, he needs to make a mount for a motor-generator on a bicycle - on such a machine he will quickly draw, cut and grind it.

By the nature of the operations performed

CNC machines can work on stone, wood and its derivatives, on non-ferrous metal, steel, plastic and composite. Everything is determined only by the power of the spindle motor - in such a unit, it is the main driving functional unit. The second value for the choice of the workpiece material is the length, diameter, coating of steel cutters - for example, if the machine is milling. If you are dealing with a drilling machine, then its capabilities and the capabilities of the milling unit are often combined. The work of the sawing machine is performed by the milling machine, and the work of the drilling machine is performed by the lathe.

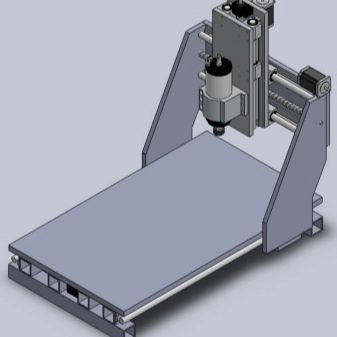

Such machines are multipurpose: they combine the capabilities of the universal (the unit cuts and grinds, drills out parts in different projections), desktop (weighs no more than several tens of kilograms, fits on a workbench with a tabletop area of 2 m2). The power of a spindle drive for processing plastic and wood, as a rule, does not exceed several hundred watts per hour consumed from the mains. For non-ferrous metal, power up to a kilowatt is already required, and for steels - 1.5-2 kW. There is often no reference to specific types of material in a multi-purpose machine. Accordingly, it is necessary to purchase cutters, drills, crowns, saw blades made of high-speed steel, as well as with abrasives.

According to the types of processing, the classification of CNC machines provides for horizontal (cutting of parts in their "lying" position) and vertical (on the contrary, these devices work with "standing" parts, cutting up and down) devices. Combined units perform cutting and drilling of parts in all three planes.

According to the parameters of the control system

The control system in CNC machines - the usual "computer" characteristics, such as: the number of megahertz of each of the processor cores, the number of its cores, as well as the number of megabytes (or gigabytes) of random access memory (RAM, random access memory). As a storage device, as in conventional desktop PCs and laptops, a magneto-optical drive ("hard disk"), SSD (solid-state "hard disk") or eMMC memory (as in single-board laptops, tablets and smartphones that perform mainly office work) is used.

However, no hardware will fully manifest itself until the control program is installed on it. Modern portable CNC machines use an operating system based on a software and graphics core Linux or Windows: for production purposes, a special "cut-down" version is "stitched" in the memory of the machine, created exclusively for work, and not, for example, for full-fledged web surfing, running games or watching videos. On it, you can only process parts, for everything else, it is not available.

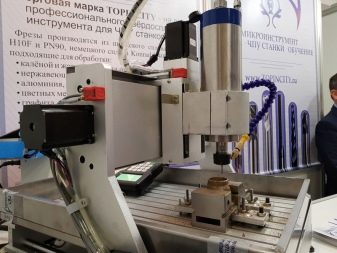

Top Models

Model 1325 - one of the best CNC machine tools, designed as an entry-level device for mastering the skills of a machine tool specialist. Low in maintenance costs - belongs to the Start class (for beginners). Performs three-axis engraving of wood blanks. Able to apply simple patterns with bilateral symmetry. Special training for a beginner when working on such a device is not needed.

The working area is 130x250x200 cm. It starts from an interphase voltage of 380 volts. It is controlled by means of the Mach3 system, equipped with a cooled spindle mechanism, operates from a control inverter, and develops a speed of up to 24,000 revolutions every minute. Lubricated by hand. Powered by Artcam software, it cuts MDF and wood, acrylic and other (including composite) purely non-metallic materials.

Model 2040 ATC CNC... Works on the basis of CNC with automatic telephone exchange. There is a built-in cutter magazine that makes it easy to select the cutter you want. She cuts, grooves non-metallic materials, cuts grooves in them and stamp blanks, mills them. Tool change is automatic. Carousel-milling model ATC CNC with a working area of 200x400x20 cm. Powered by a three-phase network.The spindle consumes up to 9 kW of power from the mains, and is equipped with 11 kW Japanese servos.

Built on the basis of a T-shaped vacuum working table, lubrication is automatically introduced into the working and the area of the rotating mechanisms. A vacuum pump removes swarf from the work area, helping to keep the work area relatively clean. Vacuum pump power - 3 kW. The machine is suitable for turning aluminum.

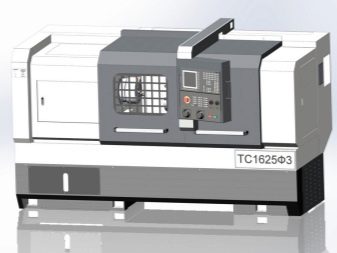

Model 1625 has a working area of 2x5 m. And also operates from a three-phase network. Desktop device with characteristics similar to the previous version. The difference is in the presence of an oscillator cutter that allows you to cut skin and matter. Cutters allow you to work with aluminum and any non-metallic simple and composite materials. Cutting accuracy - 10 micrometers. It is possible to continue engraving non-metals and aluminum from the point of interruption of the operation.

Other models allow you to work with steel, bronze, duralumin, but their power, dimensions and equipment turn out to be at least several times higher in cost than the three models described above. They support 5-axis (5-axis control) operation. The most expensive machines are equipped with a laser cannon that generates up to hundreds of watts of power at a point with a diameter of less than 1 mm, which allows cutting steel with the highest precision.

Components

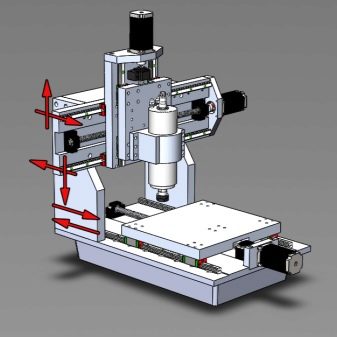

The usual set of CNC machines includes a frame (bed), gearboxes and feed unit, headstock and tailstock, rod mechanism and support. All parts and assemblies are fixed on the machine frame, without which this device cannot work. The gearbox (gearbox) is responsible for transmitting torque from the spindle drive. Further, the transmitted torque is received by the caliper functional unit.

The headstock includes the gearbox and the spindle itself, clamps and rotating parts that turn the component to be turned. With the help of the tailstock, the turned part is fixed from the opposite side - at the moments of machining the central part of the workpiece. The core is a reamer or a drilling cutter that sets the alignment.

This element is rigidly connected to the tailstock. The slide determines how firmly the cutter is fixed and in which directions it moves. The completeness of the CNC device is complemented by a vacuum table, a vacuum pump that collects chips, and a cooling device for cutting tools. To be able to move away from the workplace for a short time, the worker (machine operator) uses a portable console.

Nuances of choice

Choose a CNC machine for the following parameters.

- Power consumption. Not every production workshop has the ability to connect to a three-phase supply voltage, not to mention private houses, for example, in a suburban residential area. Household wiring is unlikely to withstand more than 3.5 kW: conventional 16-amp automatic machines installed on the meter, as well as the meter itself, cannot operate at a load current of more than 16 amperes. Choose machines with a power of no more than 2-3 kW.

- The spindle motor speed must be at least 10,000 per minute. Otherwise, the turning of the parts will turn out to be of not quite high quality, in particular, it will be problematic to carry out fine engraving and turning with the smallest contours.

- Working with metals... Even not quite powerful machines with high efficiency and revs from 20,000 rpm can grind at least steel 3 and bronze. Metalworking greatly expands your relevance as a master of your craft.

- The working area should be as large as possible. This will allow you to either grind a larger number of parts in one plane, or produce larger blanks.

- Ease of fixing and changing cutters, drilling cutters - without this characteristic of a CNC device, your efficiency, accurate execution of large plans may suffer, in particular, due to a properly loose cutter, you risk getting a significant percentage of rejected parts.

- Workmanship and cooling system. How high quality and reliable these two components turn out to be determines not only the service life of cutters and drilling cutters, but also the overall service life of the mechanics in the CNC machine.

- Vacuum suction and visor... These two factors determine how clean your workplace will be after the completion of the work.

Working with DeskProto, VCarve Pro, ConstruCAM-3D, ArtCAM, NX CAM, SprutCAM and Mach3 software differs only in the software interface and set of functions.

Applications

The use of CNC machines is justified in the stone and woodworking industry, in the metalworking industry and even in the car service, where, for example, replacement parts are machined for carburetor engines of cars. But a CNC machine will help in the manufacture of decorative figures, jewelry, and also mills or cuts blanks from any steel using a laser. The CNC performs, for example, the cutting of MDF doors (door leaf), turning of parts for locks and anti-burglar fittings of metal-plastic windows. This list threatens to become endless. One of the typical examples is the carving of bronze figurines from portraits of prominent personalities drawn in three-dimensional format.

Adjustment and modernization

Setting up the machine for work is carried out according to the following scheme.

- Find the right cutter for your application. Check the sharpness of its cutting edges.

- Place the torch in its designated chuck. Check if it is securely fixed.

- Start the machine without blanks.

- Program the device. Old CNC-units are programmed using punched cards, newer ones - using the same AutoCAD (entering the parameters of the machined part).

- Suspend the machine, and place the workpiece on the stage, turn on the pump. Restart the machine.

- After turning the part, stop the machine and remove the turned workpiece. Place the next one. If necessary, change the entered parameters and start the machine.

- If multiple turning (copying) of parts is to be performed, then place the required number of workpieces in the work area, program the CNC device, and start the spindle. Parts are turned automatically.

If the machine does not provide for automatic oil supply, then, according to the instructions, introduce this lubricant yourself, for example, after turning each part.

Not all machine models lend themselves to modernization. At the first stage, it is only possible to install a more high-performance single-board on-board computer - and change Windows, for example, to a Linux system.

It is possible to mount a chuck for larger cutter and drill shank diameters, but this will also require a higher speed and / or powerful motor per spindle.

How to choose a CNC machine, see the next video.

The comment was sent successfully.