Varieties of canting machines and the rules for their selection

Currently, various types of lumber are widely used in construction. For their manufacture, special equipment is used. Today we will talk about the features of canting machines designed for the production of timber.

general description

The canting machine allows you to perform longitudinal sawing of logs to obtain a bar or unedged board. This unit can easily process even low grade wood or wet small meter.

Pass-through equipment can be installed separately, or can be part of a single production line at the enterprise. The canting machines are reliable in operation, they are produced in full compliance with the safety rules at work.

Species overview

Such woodworking equipment can be of various types.

-

Milling and canting. Such units should be used to form a four- or two-edged cant. They are distinguished by the maximum speed of wood processing. Such devices are equipped with special milling heads. Sometimes they are supplemented with circular saws, which makes it possible to end up with two or four more boards from the side parts.

- Circular saws. These machines are supplied with circular saws. They have a significant diameter. In the passage areas, the logs are fixed using a special tray. In its lower section there is a movable chain with hooks; when moving, it will move the wood forward.

Currently, carriage types of such equipment are produced. In this case, the logs will be fixed in the movable carriage and move along with it.

- Horizontal band saws. These woodworking machines keep the workpieces stationary. Only the saw system moves. Such designs are distinguished by the most compact dimensions. They are often purchased for small workshops.

- Vertical band saws. The units will be the best option for large-scale production. Moreover, they have the most complex design. The technique is characterized by maximum precision and the minimum amount of waste generated. The resulting sections will not require additional processing.

- Corner. The structures are also equipped with circular saws, they are fixed at right angles to each other. The devices allow you to receive both a bar and a board.

- Cup cutters. This variety is used for profiling a bar and for planing a mini-bar. The cup-cutting machine will make it possible to make special fasteners in the form of rectangles or semicircles on lumber.

They are necessary to connect the logs to each other when constructing walls or other building structures.

Popular models

Next, we will get acquainted with the features of individual models of such woodworking machines.

-

SB-25. The unit is used for accurate sawing of a small meter and forming a two- or four-edged bar. Its design consists of a saw carriage equipped with two circular saw blades, a pivot center, a bed, a clamping device and a clamp. SB-25 has a total weight of 1000 kilograms. Most often it is purchased for work in large enterprises.

- Arctant 652. This canting machine is used for longitudinal sawing of logs in order to obtain unedged boards. Such equipment is often purchased for sawmills. The equipment is easy to operate and maintain.It has high performance even at low temperatures. Arctant 652 is resistant to contaminated raw materials.

- CR 58. The machine of the double-disk type allows you to saw workpieces into a bar, edged and unedged board. The technique is equipped with sharpened carbide-tipped circular saw blades. This design allows you to get high quality sawn timber. KP 58 is equipped with a saw head, bed, slats, log clamps. The device has an automatic sawing system.

- PDU-2 UT. The machine allows you to perform horizontal, vertical and angle sawing. The equipment is a whole circular sawmill. In its manufacture, saw blades of large diameter are used.

- Arctant CLS-560. This crawler-fed woodworking machine allows you to produce unedged lumber in sawmills. The technique has a high performance indicator. In addition, it boasts a long service life, ease of setup and management. Arctant CLS-560 is ideal for processing medium to thin woods. The model can easily process workpieces with defects (knotty, contamination).

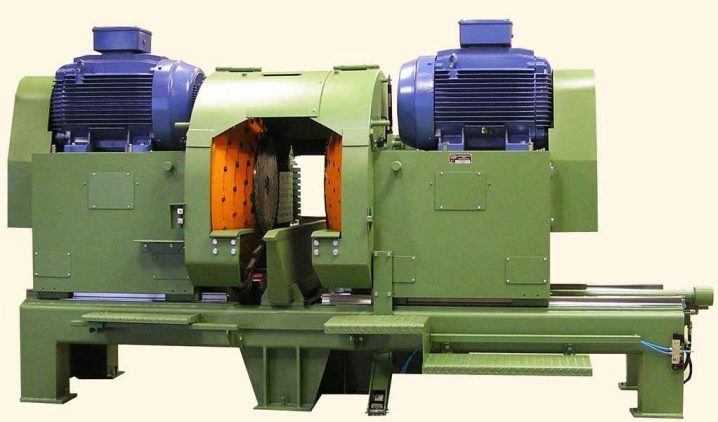

- Walter TD 450 KBA. This double-shaft canting disc machine is used for high-quality sawing of round wood. Each shaft can have up to four sharpened saws. Walter TD 450 KBA also has a high productivity, high processing quality. The technique is very reliable in operation. It is sold together with a convenient control panel that displays the operating mode and load.

- Stiletto BSP-45. This walk-through canting machine rips a log to produce a slab and a double edged cant. The model is distinguished by a fairly smooth adjustment of the feed rate, a high level of operational safety. All electrical equipment in the device complies with European standards. The sample allows you to achieve the ideal geometry of the processed lumber.

- SLD-2P-800. The model is supplied with two saws. It makes it possible to form a bar or slab from a solid log in just one pass. The device can be used both independently and as part of a single production line. SLD-2P-800 provides the most smooth feed of raw materials, this is achieved through a special control system.

Secrets of choice

Before purchasing such woodworking equipment, you need to pay attention to some of the nuances. The maximum cutting diameter is important. It is this indicator that will determine how many revolutions it takes to process wood.

And also pay attention to the maximum and minimum thickness of the center bar. The larger the range, the more possibilities the machine has.

Remember that the canting device can have a mechanical or automatic feed of workpieces. The second option is carried out with the help of special rollers, in the process of their rotation, the logs are fed to the processing site. The automatic system is considered to be more convenient and modern.

When choosing, look at the feed control range. Some machines have only one speed, while others make it possible to determine this parameter independently.

The power of the engine in the equipment is also important. Most often, it uses twin-shaft squared motors, the power of which can vary from 30 to 90 kW. The choice will depend on the amount of work, the characteristics of the raw materials.

The comment was sent successfully.