JET machine overview

The choice of machine tools for an enterprise is an extremely important and responsible matter. Among the many models and manufacturers, it is necessary to choose high-quality products with wide functionality. These criteria are met by the products of the JET company, which is firmly entrenched in the world market for medium and large equipment.

Peculiarities

The machines of this manufacturer are known all over the world. The reason for this is not only the high quality of the equipment, but also the geographically wide supply network. The initial country of origin was the United States, but soon the company entered the European market by opening factories in Germany, and then began to expand into the Asian market - in China and Taiwan, where most of the production facilities are currently located.

Such a developed system of enterprises allows selling products all over the world, which is one of the key features. As for Russia, several large industrial companies are engaged in the supply of JET equipment, due to which the consumer has no problems in finding a suitable machine for himself.

The American company is actively expanding its range and offers customers products for the processing of wood and metal, including many subtypes of units, depending on their scope and operation.

At the moment, among the entire model range, one can distinguish combined, bending, hacksaw, carpentry, polishing and many other product variations, also including a narrow band sawing machine. The assortment is formed within the series, which allows the consumer to choose the technological basis he likes, and already within its framework to select the machine according to the technical characteristics and other parameters.

Variety of models

By wood

JET JWL-1221 - one of the best lathes designed for professional work of a wide variety of purposes... The design features and high quality of the mechanisms allow you to perform complex work with different types of wood. It can be either desktop in the original configuration or floor-standing after the installation of the corresponding racks and mounts. This model works with small workpieces, but when the worktable is lengthened, it becomes possible to process large material.Unlike cheaper amateur predecessors, it has a wide cast-iron bed, which is responsible for the strength and reliability of the unit as a whole, as well as reducing the level of vibration.

The main machining mechanisms, or rather the spindle and its cutting parts, are mounted on reinforced bearings and begin their rotation by means of a belt and its operation with an asynchronous motor. There are 6 pairs of pulleys to select the gear ratio. In order to reinstall the belt, loosen it or tighten it, you must use the linkage. Its use eliminates the need for any tools, thereby simplifying operation. A 24-position indexing device is integrated to ensure that the wood is processed as precisely as possible.

The complete set includes handcuffs 150 and 250 mm wide for turning tools, a faceplate with a diameter of 76 mm, as well as a four-pronged drive center, a rotating stop center, a knockout rod and two hinged holders for the power cable and additional small pieces of equipment. The tailstock quill travel is 57 mm, the distance between centers is 450 mm, with an optional improvement - 560 mm.Power consumption 0.73 kW, swing diameter over bed 318 mm. Dimensions 853x280x450 mm, weight up to 55 kg.

JET JTS-1600 - professional panel saw woodworking machine for industrial use... One of the main advantages of this universal model is that its basic package includes many installed units, so the consumer does not have to buy anything. The cast iron work table can be supplemented with sections to increase space and processing possibilities. The secure rip fence is attached to the base and moves through the eccentric stop.

There is a movable carriage with a stroke of 1600 mm. With its help, the material is fixed. And also it is carried out due to the action of the clamp or the longitudinal stop.

Other features of this machine include the presence of a scoring disc driven by the main disc... Built-in tilt height adjustment and saw module mounting. And also the user can facilitate the operation of the unit by connecting the sawdust removal system with their subsequent suction both from the lower cavity and from the upper disc casing. There are 3 removable extenders in total, making it possible to choose the optimal combination depending on the task being performed and its complexity. Many experts note the wide starting configuration and variability in the operation of the JTS-1600.

The power consumption is 3.8 kW, the voltage is 400 V. The dimensions of the movable table are 1600x270 mm without expansion modules, with them the indicator increases by 560x680 mm. Maximum width up to the end stop limiter 2200 mm, cutting length up to 1350 mm. The scoring disc at idle speed reaches 8700 rpm, while the saw blade reaches 4700 rpm. Adjustable tilt angle from 0 to 45 degrees. In this case, the cutting depth is 100 and 80 mm, respectively. Machine dimensions 1600x2800x865 mm, weight 250 kg with all modules.

JET JWSS-18B is a very popular jigsaw model, the functionality of which surpasses many of its counterparts from other manufacturers... When creating this machine, JET decided to focus on the reliability of the design and the accuracy of the way of working. The basis of this unit is a parallelogram drive mechanism for the swinging part, which has a number of features that facilitate operation. The first benefit of this technology is the ability to raise the top of the frame, making it easier to cover and position the workpiece.

The lower position can be adjusted manually, thereby achieving the most correct position of the material being processed.

The second advantage of the technology is the mode of operation with longitudinal web pumping. It is necessary for more intensive processing of the workpiece when roughing wood. Thus, the user can adjust the technique to the length of the file and the thickness of the workpiece. And you can also adjust the workflow depending on the requirements for speed, accuracy and frequency of cutting. The work table is made of strong sheet steel fixed to the base.

To change the angle of the cut, tilt the frame with the saw blade tensioned.

The machine works without a pin. The upper part of the file is fixed by means of an eccentric, and the lower part by means of a clamp in the adapter.

To simplify installation, there is a slot in the desktop, which is extremely useful for positioning workpieces with a threaded file. It is possible to blow off sawdust from the marking using an adjustable air duct and a pump. To keep the workplace clean, you can connect a vacuum cleaner with a nozzle... The package contains a set of five saw blades and two adapters for their installation. Power consumption 0.3 kW, frequency of sawing strokes is adjustable from 400 to 1550 per minute. The length of the blade reaches 130 mm, the angle of inclination is from -45 to 45 degrees. The maximum workpiece width is 474 mm, the cutting depth is up to 48 mm, the dimensions of the working table are 536x287 mm.The air outlet has a diameter of up to 63 mm, the dimensions of the JWSS-18B are 780x400x420 mm, and the weight is about 25 kg.

For metal

JET MCS-275 is a cutting machine that successfully competes with the products of other well-known manufacturers... The main field of application is sawing round metal workpieces of various profiles and diameters. The design provides for the operation of a 275x32 mm disc. Separately, it is worth noting the versatility of the cutting head mechanism, since it can be rotated 45 degrees to the left and right, thereby making it possible to make the processing the most variable. Thanks to the use of this design feature, it is possible to saw round workpieces at right angles with a diameter of up to 80 mm, as well as profiles with a section of 100x50 mm. For work in production, a modification is provided for changing the power system from 220 to 380 V.

There is an on and off button on the handle, located at the motor housing. The machine has small dimensions 900x550x800 mm, which allows you to place it in your home workshop. The manufacturer has equipped the MCS-275 with a quick-clamping vice for the most convenient and efficient installation of the workpiece. If you are going to use the equipment for numerous batch production, then it will be very useful to use an end stop that adjusts the required length for each workpiece separately. In order to improve the technical characteristics in comparison with its counterparts, JET decided to install a 1 kW motor on this machine. It allows the saw blade to rotate at up to 42 rpm.

In the event of unforeseen situations, the operator can urgently stop the operation of the machine by pressing the emergency stop button of the engine. The advanced design and high performance are a consequence of the heating of the driving units, so the manufacturer took the drip lubricant as the basis for the cooling system. The coolant tank has a capacity of 2.5 liters, the weight of the machine is about 105 kg with all installed components.

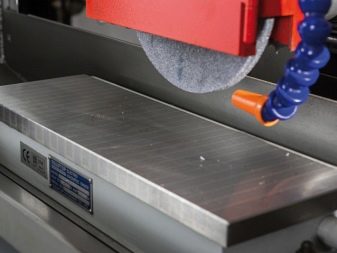

JET JPSG-0618SD is another surface grinding machine. This model is fully automatic, which excludes human actions during the work process. Now the user will only need to set the necessary settings and periodically service the equipment, monitor its condition. The machine has high accuracy and reliability, which are extremely demanded in professional production - at large enterprises, in aircraft construction and design craft.

Grinding on JPSG-0618SD takes place in two modes - roughing in the range of wheel feeds from 9 to 50 microns, and finishing from 1 to 9 microns, due to which a full cycle of product processing is achieved. In the equipment setup program, all the necessary data are indicated - the size of grinding in microns, as well as variations in the approach of the spindle with its subsequent retraction at the end of the process. You can specify the amount of material removed in one pass, the vector and the processing feature. Therefore, the result of the work largely depends on the user's skills, and the machine will do the rest itself in the highest quality.

The size of the working table is 406x1020 mm, while the longitudinal movement is 1060 mm in automatic mode, while in manual mode - 1100 mm. The constant cross feed rate is user programmable from 20 to 320 mm / min. The spindle speed reaches 2850 rpm, and a mechanism for its rapid rise is also provided. So that the units and the most active parts of the machine do not overheat, the manufacturer has equipped the product with an automatic lubrication system. The maximum convenience in the operation of the machine is provided by the display panel, which indicates the positions of the spindle along different axes, the parameters of the beginning of the grinding process are displayed.

The extremely wide range of accessories includes many useful accessories - an electromagnetic table, a grinding wheel with flanges, a balancing stand, a diamond pencil, a lamp for illumination and a protective shield with adjustable mounting feet.

JET JBSM-75 - multifunctional belt grinder... Designed for cleaning welded seams, deburring and other elements on the surface of metal workpieces. It is also used for sanding surfaces of both already processed and rough versions of the material. This tape device is used in many places - auto repair shops, medium-sized enterprises, design bureaus and private workshops. The maximum sanding width on the JBSM-75 is 75 mm in width and up to 500 mm in length. To prevent the tensioning bands of the machine from slipping, they are equipped with a rubberized surface.

To achieve high efficiency and safety for the equipment, the manufacturer set the maximum belt speed at 29 m / s with its total length of 2000 mm. The drive of the machine is significantly strengthened and has a power of 3 kW, which corresponds to the professional class of equipment. The unit is connected to a three-phase power system with a voltage of up to 400 V; the frame is tilted from -15 to 30 degrees. The safety system is represented by a protective transparent screen, a top tape cover and an emergency engine shutdown button.

Fastening of the floor type through screws, the basis of the structure is a solid wide bed. To ensure that the workplace remains clean during operation, the manufacturer provides a dust extraction element, to which a chip suction unit with a nozzle diameter of 97 mm is connected.

Components and spare parts

Based on the reviews of some machines, you can see that JET tries to expand the functionality of its products by means of third-party components, which may not be initially installed on devices.

For the convenience of consumers, they can purchase the appropriate parts directly from the manufacturer.

At the moment, JET company sells machine vices, abrasive wheels, work table expansion kits, fixing plates and many other items according to the type of machine and its specification.

Moreover, these can be both separate mechanisms and components from other parts. For example, there are a number of components that provide a more stable operation of the motor, cutting units, and measuring devices.

It is worth noting the possibility of the buyer to install a lubrication cooling system if it is not provided for by the basic configuration of the machine. This possibility can also be used in a situation with a malfunction or breakdown of any part of the structure. At the same time, their replacement and installation are simplified in order to improve the convenience for the buyer.

The comment was sent successfully.