How to sharpen a chisel?

Any construction and work equipment must be kept in the correct conditions - if untimely and improperly maintained, its functions may be impaired. One of the simplest but very useful tools is the chisel. To get the best performance, it is important that it is as sharp as possible. It is possible to achieve the desired result with the help of specialized devices or improvised means.

General rules

The chisel is a carpentry tool that allows you to work effectively with natural wood. Outwardly, it resembles a screwdriver, due to the presence of a handle and a long metal work surface. The handles are usually wooden, but modern versions are created using polymeric materials. The working part of the chisel is made of durable metal, which is beveled at the end.

Depending on the purpose of the tool, the bevel angle, thickness and width of the blade can be different.

Whatever the appearance of the chisel, the main thing for it is the sharpness of the blade. If it is dull, then working with such a tool on wood is extremely difficult, and sometimes even impossible. To solve the problem, it is necessary to sharpen such a product. It is important not to spoil the inventory, to do everything right, the main thing is to know at what angle the inventory should be sharpened, what to use, and what materials at hand can help in the process.

To work correctly with the tool, you need to understand what to sharpen and how to do it.

First of all, it is important to understand what parts the chisel consists of.

-

Lever. It is often made from such types of wood as oak, beech, hornbeam, birch, acacia. Modern options are created thanks to polymer materials.

-

Canvas. This is a metal blade that has different widths and thicknesses depending on the work to be done with the chisel.

-

Chamfer. Changing the thickness of the blade at the end of the blade to a smaller side.

-

Cutting edge bevel. The thinnest and sharpest part of the instrument.

It is the cutting surface that must be kept in an acute state, make sure that chips and bends do not form on it, otherwise the chisel will become useless in work.

When planning to sharpen a chamfer to improve the cutting performance of an edge, it is important to correctly set the angle at which the tool is located and to use the correct materials for the job.

What angle should you sharpen?

The chisel is an important tool because there are certain standards and GOSTs for working with it. To sharpen the product correctly, it is important to maintain an angle of 25 ° + 5 ° depending on the purpose or thickness of the chisel. If the blade is thin, then the bevel will be shallower; if the blade is thick, it will be steep.

For slotting work, the angle is 27-30 °, which protects the cutting surface from deformation under strong impact forces.

The optimal angle that is suitable for sharpening most of the chisels is exactly 25 °, which allows you to have a fairly sharp and reliable tool that can cope with the tasks assigned to it. When it comes to performing delicate carpentry operations with trimming shaped elements, removing thin layers of wood, the angle of the tool should be 20-22 °.

When sharpening this carpentry tool, it is important to know that the chamfering should be 5 ° different from the sharpening angle of the cutting edge for a better result of the tool. The choice of the cutting angle of the blade will also depend on the tool that is used for sharpening. For manual processing, the inclination of the product will differ from that of machine tools.

How to sharpen with different devices?

Work on sharpening chisels can take place both at home using improvised tools, and in specialized workshops. If you do not want to use someone else's services, you can do all the work yourself.

For sharpening a chisel, it is important to have three components.

-

Abrasive materials used for the initial processing of the blade.

-

Materials for grinding the obtained result and bringing it to the desired level.

-

A holder that allows you to fix the chisel at the desired angle. There is an option that allows you to work with abrasive wheels of an electric grinder, as well as a manual one, for which you need to have bars and sheet abrasive.

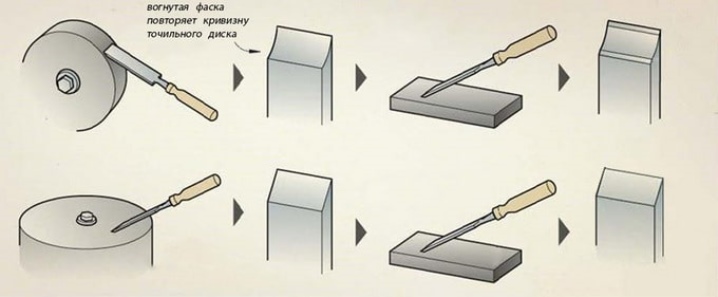

In the process of sharpening a chamfer, there is a possibility of variability, choosing between manual and mechanical methods of influence, and exclusively manual processing is suitable for finishing the cutting edge. It is important to select the correct grit size.

For sharpening, it should be 300-400 microns, and for the final processing of the cutting surface edge - 50 or 80 microns.

If you have to work with semicircular tools, then the technology for working with them does not differ from flat ones, only the number of stages increases by which each section of the chisel is processed.

To sharpen carpentry tools, you must have the following devices:

-

horizontal and vertical machine;

-

sharpener;

-

sandpaper with abrasives of different grain size, applied to the bar;

-

abrasive materials on the sheet;

-

fixing devices and frames for installing the tool;

-

materials for polishing the final result.

In order to properly sharpen the chisels, it is important to be able to use all the possible tools for this task.

On water stones

One of the most popular options for chisel chamfering is using the wet stone method. To carry out the work, you need to soak the stones for 5-10 minutes, and during the processing, irrigate abrasive materials with a spray gun all the time. An alternative would be to carry out the procedure directly in the aquatic environment.

To ensure correct processing and formation of an even chamfer and sharp cutting edge, stones with different grain sizes must be used.

The algorithm includes several steps.

-

Using a stone with a grain size of 800 grit. This is a coarse abrasive that allows you to make the initial surface alignment of the chamfer. For those instruments that are in good condition and do not have gross damage, this step can be skipped.

-

The use of a stone with a grain size of 1200 grit - used for intermediate surface treatment of the blade.

-

An introduction to 6000 grit stone - Necessary for finishing the surface and obtaining the sharpest and most even incisal edge.

For those who wish to make the instrument absolutely smooth and mirror-shiny, you can use a stone with a grit of 8000 grit, which is necessary for performing delicate polishing work.

In this version of sharpening a chisel, it is very important to use wet stones in the correct sequence, otherwise it will be much more difficult to achieve the desired result, and it will take significantly longer.

On the grindstone

Depending on the degree to which the chisel has become dull, it is necessary to use the appropriate material. For difficult cases, where you need to maximize the impact on the chamfer, it is important to use a machine or, as it is called, "grinder".Such a sharpener is needed if there is a need to change the angle of sharpening of the chisel or eliminate chipping and deformation of the tool.

Sharpeners are less popular than other sharpening tools because they run the risk of overheating the blade, making it brittle.

In case of any errors on the grinder, it will be necessary to redo the work again, while cutting off the singed edge of the cutting surface, which changes the overall length of the product.

They are trying to solve the problem by using aluminum oxide discs, which have a looser structure and do not so much affect the metal of the chisel. If you monitor the speed of the machine, moisten the abrasive in a timely manner, then the risk of spoiling the tool will be minimal. Having a choice, professionals try to use other methods of sharpening chisels.

Using a trolley

If there is no possibility and desire to use ready-made sharpening machines, you can make them yourself. A manual grinder can have different dimensions and appearance, but the principle of operation will be the same for everyone.

The device of such devices will look like this:

-

carriage - thanks to it, it is possible to move the chisel over the abrasive material;

-

inclined platform with clamp, allows you to set the desired angle of the tool placement for a specific task.

The manual sharpening device includes two grooved surfaces into which the chisel is inserted. Thanks to the clamps, it is possible to immobilize the tool. The inclined surface allows you to set the desired angle of inclination of the product.

To form the trolley holder, a workpiece is used, on which a bevel is formed with an angle of 25 °, the length of the cut is 1.9 cm. The workpiece should be fixed with double-sided tape. From below, stepping back 3.2 cm from each edge, it is necessary to drill holes.

Thanks to the slotted disc, it is possible to form a groove for installing and fixing the chisel. It is also necessary to make a clamp, at the ends of which holes for screws are made on both sides at a distance of 3.2 cm. The next step is to glue the handle to the clamp. Once all the elements are ready, you can assemble the entire structure.

Using a trolley, you can not only sharpen the chamfer, but also make a micro-chamfer, creating an additional slope at the end of the blade. For this, the carriage must have a switch that will allow you to correctly align the tool and sharpen its thinnest edge.

On sandpaper

In the process of sharpening chisels, it is not necessary to use a power tool or create sharpening installations; you can take a more affordable, but no less effective material - sandpaper. Before proceeding to the use of this abrasive, it is worth assessing the degree of damage to the product. If there is a need for significant impact, it is better to initially use a grinding disc, this will significantly speed up the process.

Once the chisel is prepared, you can start working with sandpaper. For optimal results, it is important to have a perfectly flat work surface. It is best to use thick glass or ceramic hob as the backing. If these materials are not available, you can take a flat board or a piece of chipboard.

The sandpaper should be well aligned and smooth. It must be attached to the substrate. The most convenient way to do this is with double-sided tape. There are also options for self-adhesive sandpaper, this is an even better option.

In the process of preparing the substrate, it is important to make several options using sandpaper of varying degrees of grain.

P400, P800, P1,500 and P2,000 polishing options are best used. It is important to apply waterproof sandpaper, since during the performance of grinding operations, you will need to regularly moisten the tool.

The work process looks like this:

-

work with the back of the chisel, for which sandpaper P400 is used;

-

chamfering on the same paper, at least 30 moves forward and backward;

-

the use of emery paper with a smaller grain size.

It is important to keep the chisel parallel to the work plane. By holding the correct position, you need an angle and applying different abrasives in the proper sequence, you can get a good result in a minimum of time. To check the quality of sharpening, you need to run the tool over the wood and remove the chips from it without effort. If everything is done correctly, there will be a layer of chips on the cutting edge.

Using other tools

With frequent work on wood, the chisels become dull pretty quickly, therefore it is important to sharpen them on time and with high quality... If there are no specialized products at hand for this purpose, and there is no possibility or desire to make your own machine with a trolley, then a grinder is suitable for such work. If you set a low speed on the tool and follow the process, you can quickly sharpen the chisels.

The sharpening process is carried out using an abrasive wheel, which is put on instead of the grinder's cutting disc. It is important to pause so as not to overheat the blade, otherwise it will become brittle and the tool will not be able to fully perform its functions. The chamfer processing scheme does not differ from other options and also requires the use of abrasives of different grain sizes.

Those who are seriously engaged in woodcarving or other joinery can purchase certified sharpening machines that can sharpen not only chisels, but also other equipment of this type.

And also on sale there are kits for sharpening chisels, consisting of a folding goniometer, which allows you to set the desired and correct angle of inclination of the tool, an abrasive bar with different types of grain size and oil.

Depending on the budget and other possibilities, everyone can choose for themselves the most convenient and effective option for sharpening chisels. Due to the variety of sizes, thicknesses and shapes of these tools, not all methods will work equally well for the options available. By choosing the right way of sharpening the tool and the tool for it, you can quickly cope with this task and stably maintain the chisels in working order.

In the next video, you can learn more about the process of sharpening a chisel.

The comment was sent successfully.