Choosing an installer's claws

Work associated with the need to climb to a great height is necessarily accompanied by the use of special tools, equipment and outfit. An integral part of an electrician's work at heights is an electrician's claws. It is about this device that will be discussed in this article. We will tell you about the purpose, types, configuration, popular models and operating rules of this special equipment.

What are they for?

So, what are freelance claws and what are they for?

This is a special equipment that is designed for climbing an electric pole.

An electrician is a specialty that is certainly associated with the use of this device.... This equipment allows workers to safely climb to the very top of the structure.

Monter's claws are different in purpose:

- for concrete supports;

- for wooden supports;

- for reinforced concrete supports.

Features and types

So, earlier in the article we already talked about the fact that these attributes of an electrician are classified according to their purpose, the material from which the support is made. Let's take a closer look at the types of monter's claws.

For lifting on a wooden support

The production and operating rules of this type are provided for and controlled by GOST 14331 - 77 “Claws for fixers for wooden and wooden supports with reinforced concrete stepsons. Technical conditions ". According to this normative document, there are three types of devices for lifting on a wooden support.

- KM - 1... Can be used on a support, the diameter of which is from 14 to 24.5 cm, the mouth of the claws is from 24.5 cm to 1 cm.

- KM - 2. For a support pillar, the diameter of which is from 22 to 31.5 cm, the mouth of the claws is from 31.5 cm to 1 cm.

- KM - 3 Can be used on a support with a diameter of 31 to 41.5 cm, the mouth of the claws from 41.5 cm to 1 cm.

Lazy KM type is characterized by a stamped platform, the presence of special lugs, with which the arcs are attached. Thanks to the latter, the leg is securely fixed and does not slip on the platform. The back surface is equipped with stiffening ribs. The pins are made of high strength steel and hardened.

But even despite this, it is the spikes that are the "Achilles' heel" of the product, they wear out very quickly.

Their condition must be constantly monitored and, if necessary, replaced immediately. These claws can withstand a load of 140 to 160 kg. The belts of the construction are wear-resistant, made of leather.

For climbing reinforced concrete supports

Like the previous type, they are manufactured in accordance with legislative regulations. Products are marked with the following markings.

- LMC... They are used for lifting on a reinforced concrete centrifuged support. They can be operated at temperatures from -20 ºС to +30 ºС. The maximum permissible load per manhole is 180 kg. Functional, durable, made of quality materials. They can be used for lifting on a support, the diameter of which is from 12.6 cm to 15 cm, the mouth of the claw is from 13.6 cm to 1.5 cm.

- LU. LU type monter claws are universal. They are characterized by the presence of an additional strap that fixes the back of the electrician's foot. Suitable for supports from 16.8 cm to 19 cm in diameter.

- KLM... Monter's claws of the KLM type are of two types - KLM - 1 and KLM - 2. Their rise is the same - 16.5 cm, but the throat is different.Claws KLM - 1 are characterized by a throat from 16.8 cm to 0.5 cm, and KLM - 2 have a throat from 19 cm to 0.5 cm.

Claws for climbing concrete

They are marked LM - ZM. They are also manufactured in accordance with TU and GOST.

Equipment

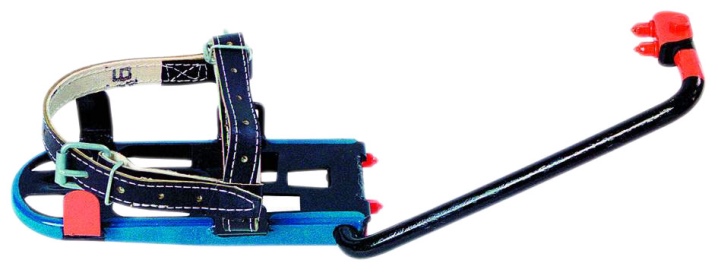

The construction of the fitter's manholes is rather complicated, although it looks like it is a simple and uncomplicated product. They consist of the following basic elements:

- leather belts, with the help of which the worker's leg is securely fixed in the support;

- supports and platforms for the foot;

- spikes that act as a retainer, they are attached to the base using a threaded connection, the condition of which must be monitored and, if necessary, replaced (spikes may differ depending on which support the claws are used for);

- metal arcs.

Absolutely all freelance claws are made in accordance with the law.

Their production, testing before commissioning is controlled by regulatory documents, SNiP.

According to this document, belts must be made of leather, stitched with thick nylon thread. The maximum load that the equipment can withstand varies from 140 to 180 kg.

Which is better?

There is no way to determine which freelance claws are better and which ones are worse. There is a wide range of this device for work at height on the market today. All claws are different. Therefore, in order to acquire the best option for yourself, you need to know the criteria by which to make a choice, namely:

- for what reason the rise will be carried out;

- product specifications - carefully study the document on claws, in which pay attention to information such as carrying capacity, thickness and material of manufacture of belts, it is also very important to look at the date of production and expiration date (almost all mounter's claws can be used for no more than 5 years);

- integrity construction and all its elements;

- compliance with TU, SNiP and GOST, the availability of quality certificates, which confirm that the product has passed all the laboratory tests provided for by law, will help to make sure of this;

- price, it is best to choose expensive, high-quality products, it is not worth saving, and even more so for questionable promotions and discounts. Perhaps the low price is due to the fact that the permissible shelf life is coming to an end or the integrity of the structure is broken;

- manufacturer - this is another important aspect of choosing and buying a reliable product, give preference to a well-known trade brand.

Be sure to visually inspect the purchase, check for the markings. A bona fide manufacturer must have all the documents for such equipment. If they are not there, it is better not to buy such a product.

Operating rules

High-altitude work has an increased danger, which is why there are a number of rules for their implementation and equipment operation. Every worker is a high-altitude worker, an electrician must know and apply the following rules for the operation of an electrician's claws.

- The equipment may only be used for its intended purpose. This means that to climb up the concrete base, you need to use claws that are designed for this material.

- Necessarily needed adhere to safety rules.

- It is worth considering the technical characteristics of the claws, because each model has a certain maximum load capacity.

- Before putting on the device, it must be checked, namely spikes and straps for deformations. Every bolt, cleat, strap and retainer must be intact. If defects are found on at least one of the parts, it is strongly discouraged to use the equipment.

- Carefully study the passport of the product. The document must indicate the expiration date and the dates of mandatory checks.

- You need to hand over claws for check at least twice a year.

Also, experts do not recommend using claws of dubious and little-known manufacturers in high-altitude work.

It is also worth knowing that the pliers' claws are not adapted for climbing on an icy support.

There is a certain permissible operating temperature, which is also indicated in the product passport.

Watch the video about the fixer claws below.

The comment was sent successfully.