Split system is buzzing: causes and elimination of the problem

Having installed a new air conditioner of the split-system type (separate outdoor and indoor units), the consumer, after a few days or a couple of weeks, is faced with the fact that the new device makes a lot of noise, which was not observed on the day of installation. The best way out is to contact the same company, the craftsmen from which installed and started up the split air conditioner. But if the company's masters did not help, and you have the skills and practical knowledge of equipment repair, then it is time to figure it out yourself, until the device finally breaks down.

Split system device

To figure out how to troubleshoot, you need to know how a split air conditioner works.

External block content:

- motor-compressor;

- cooling fan;

- condenser with a drain tube to collect moisture;

- external circuit, driving the refrigerant.

The indoor unit contains:

- electronic control unit with display;

- evaporator-cooler with the inner part of the circuit communicating with the outer one through the freon circulation tubes;

- mechanical convector - sucks in warm air, gives it back after cooling.

No air conditioner will cool indoor air without removing excess heat and moisture outside.

Noise standard

Manufacturers of climate control equipment adhere to generally accepted standards for the noise emitted by any household appliances they produce. For split systems for an external unit, this is 38-54 dB. The indoor unit is much quieter: its noise pollution is only 19-28 dB. For comparison, in a reading room or office, the noise is 30-40 dB, on a city street and inside a car - up to 70 dB, near a bump stop or a petrol mower - up to 90 dB.

The requirements for the noise level of the outdoor unit of split air conditioners are not very high. Turning on the air conditioner, the owner of the room closes the windows, and the noise of the outdoor unit will not bother him: the quality of the "branded" device is excellent. However, neighbors may complain about the increased noise, whose windows are always open in summer.

Accumulated dirt

In dry weather, the wind carries dust that settles on the outdoor unit of the air conditioner, windows and other structures that communicate with the outside air. Also, nearby growing trees, for example, poplar, are a source of fluff, pollen, flower petals, penetrating through the drainage slots of the outer block housing and settling inside on everything in a row. All this collects dust on itself - a layer of dirt is formed.

To clean the outdoor unit of the air conditioner without disassembling, use a high-pressure washer that blows out all the dirt from the unit with a spray jet of water... This is what the company workers do, servicing the air conditioners on demand.

In the absence of a pressure washer, the housing is removed... Dust and debris are swept out of the pallet (bottom wall of the case). The fan blades, internal grilles and drainage slots, fan and compressor are washed. The insulation of the wires and the insulation of the tracing tubes are checked for damage. Then the block is allowed to dry - in the heat it will take only a few hours. Then they put the case back and check the device for previous noises.

Unsatisfactory compressor performance and wear

Like any motor, the compressor (freon blower into the cooler) includes a rotor and a stator. It works under constant load - it creates a pressure of liquefied gases of 10 or more atmospheres.Its rotor spins noticeably slower than idle. The situation in the compressor gets worse with the speed of the falling dominoes.

- A dusty motor generates excess heat much worse than a clean one, and dust and dirt retain heat.

- Even a short time interval of 5-20 minutes, during which the system will lower the temperature in the room, for example, to 22 degrees, is prohibitive for the compressor.

- Constant overheating dries the lacquer of the enamel wire from which the winding is made. This varnish cracks, turn-to-turn closures appear. The winding resistance is reduced.

- The consumption of electricity increases - especially the starting current increases when switched on.

- The motor burns out, knocking out the automatic fuse on the electrical panel.

To reduce the accumulation of heat from the compressor in the compressor itself, it is regularly cleaned of dust and dirt. Perfect option - disassemble it, clean and lubricate. If the oil is depleted in it, then it will work normally for another 10-15 years. Best of all, the service center for the repair of refrigerators and air conditioners will cope with the restoration of the engine. The craftsmen pour a special reagent into the motor, which determines by the changed color of the oil how much the enamel has been damaged on the winding enamel wire.

If the winding is burnt out, the “killed” compressor is replaced with a new one.

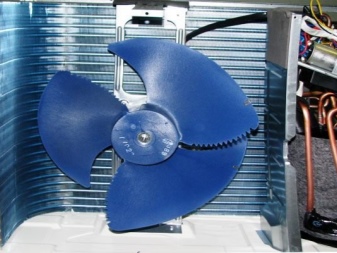

The fan crackles and thunders

After removing the protective grill, the propeller is scrolled to see if it touches the elements of adjacent structures, while crackling would be heard. With a curved ("walking") movement of the propeller, the engine is disassembled and the bearings are checked for worn balls and broken cages, a curved axis. The fact is that a “crooked” or split propeller breaks the mechanics of the fan, and you can hear the crackle and creak of broken bearings. The broken propeller is replaced. Defective balls and crowns are also replaced with new ones. The curved axis is either aligned and balanced, or a different one is set - from the same motor.

Task - ensure smooth, jitter-free rotation of the propeller... Having dripped a little oil into the bearings, the motor with the propeller on is suspended on a bendable support and turned on, allowed to run for a few minutes. If the fan does not vibrate and does not swing the support, the motor is reopened, lithol or solid oil is stuffed into the bearings, collected and put back into the block. If the winding is burnt out, then a new motor is installed. The convector (fan) of the indoor unit has the same problem. The motor is dismantled, cleaned and lubricated once a season or six months. Worn balls and a broken propeller must be replaced.

Worn vibration dampers

A good and cheap vibration damper is a rubber gasket. They absorb vibration from the outdoor unit, which is secured with steel brackets and hangers. Otherwise, vibration and noise are easily transmitted through the load-bearing wall of a house or building. Low-quality rubber will quickly burn out and crumble in the sun for a year or three, and sound insulation will be broken. There must be rubber gaskets under the bolts. Don't skimp on good rubber: it must be of the same high quality as the rubber rings for self-tapping screws, with which the roofing sheets are attached to the roof lathing.

Rubber can reduce the noise level from the outdoor unit by 10-15 dB.

Other problems

When bevelling the case of the outdoor unit, the reason for the hum of the outdoor unit is the uneven installation of the brackets holding it. There are noisy models of air conditioners that give out hum and hum even on a perfectly flat wall with suspensions exposed along the horizon.

Air conditioners, on the manufacture of which the manufacturer significantly saves, are distinguished by a high level of noise even in an economical cooling or heating mode. Rubber is taken from car tubes that are not suitable for their further use. If there is no thermal insulation on the freon tubes - buy and install it. The humming is emitted, for example, by a poorly assembled transformer of the indoor unit.Remove the case, put rubber gaskets in places where they should be, check the transformer and other components.

For information on the reasons for the buzz of the split system, see the next video.

The comment was sent successfully.