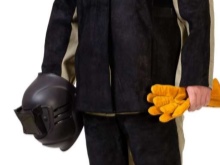

Split welder suits

The peculiarity of the welder's work is the constant presence of high temperatures, splashes of hot metal, so the worker needs special protective equipment. Split suits with all the necessary characteristics are popular.

Characteristic

A welder's suit must meet many requirements:

- in addition to strength and resistance to mechanical stress, it must be moisture resistant;

- he must create comfort while performing complex work, not hinder movement;

- one of the main requirements is the ability to provide a high level of protection against high temperatures in the presence of open flames, sparks and hot metal particles;

- it should not be affected by chemicals;

- it is necessary to preserve the protective properties during the entire period of operation.

Split welder suit fully meets the declared characteristics. Usually it has the highest level 3 of protection, that is, it can work at a distance of 0.5 m from the fire source, it can be used in closed rooms, welded seams in a tank, container, pipeline. Natural material is used for its manufacture, which is obtained in the leather industry by dividing the leather into several layers. The split section is located under the face layer. After special processing, work shoes, gloves, overalls are made from the split.

As a rule, a set consists of a jacket and pants. Since work can be performed not only indoors, but also outdoors, in different climatic conditions, summer and winter models are distinguished. The insulated suit allows you to work at very low temperatures, it perfectly withstands atmospheric precipitation. A one-piece suit with padding polyester insulation provides excellent protection from both hot metal and weather conditions.

But split is a dense, heavy material, so a combined suit is often used for indoor or outdoor work in summer. Split leather covers the front of the jacket and trousers. A set of tarpaulin or other material in combination with split wood also provides a high level of protection.

Advantages and disadvantages

Split suits have advantages over other materials. They have many advantages:

- provide the highest class of protection due to heat resistance;

- high density (on average 550 g / m2) increases resistance to mechanical stress;

- withstand low temperatures, the influence of moisture, chemicals;

- have a long service life without degradation of performance.

However, there are also some disadvantages. Due to the high density of the material, there is no air exchange. The impervious one-piece suit makes the worker feel uncomfortable. In the constant presence of high temperatures, it will be hot, overheating may occur.

To solve the problem, perforation is applied to the overalls, but this leads to a decrease in protective properties. In addition, the use of high-quality natural materials significantly increases the cost of the product.

Browse brands and models

There are many worthy manufacturers on the modern market. They produce both solid-grain and combined, summer and insulated models. The products meet all modern requirements.

- For example, the products of the Ursus company are in demand. The brand not only produces overalls, work shoes, personal protective equipment, but also supplies its products. One of the company's products is the Welder suit. This is a winter combo model, its purpose is to protect against sparks and molten metal particles. The top is made of 530 g / m2 tarpaulin impregnated with a fire retardant substance. On the front, the garment is equipped with 1.3 mm split pads. Cotton lining. The jacket is insulated with three layers of batting, trousers - with two. The jacket has a hidden fastener, there are pockets in the side seams.

- For any welding summer and demi-season work, the product "Bastion" from the brand "Vostok-Service" is perfect. This major brand is one of the leaders in the development and production of specialty products. The costume is made of canvas with a fire-resistant impregnation. The fabric has a density of 550 g / m2. The front parts of the suit are reinforced with split leather pads. The loops and buttons on the jacket are in a hidden fastener, the trousers are fastened at the side. There are internal pockets in the seams of the jacket and the invoice in the trousers. In order not to rub the skin of the neck, there is a coarse calico patch on the collar. Since the suit is designed for summer work, it has ventilation holes. Their placement is the yoke of the back and the lower part of the armhole.

- The Belarusian company "Labor Safety" has been on the market for more than 10 years.... Among its partners is the well-known Russian brand Technoavia. One of the company's products is a one-piece suit. For it, a material with a thickness of 0.9-1.2 mm is used, the lining is made of coarse calico. The suit provides 3 class of protection. If the storage conditions are observed, the manufacturer gives a 5-year warranty.

Choice

To choose the right welding suit, you need to consider some nuances.

- First of all, one should analyze the advantages and disadvantages of materials of manufactureto find the right one for the working environment. And you also need to remember that there are winter and summer models.

- It will not be superfluous to try on clothes... It should be comfortable. Both tight and too loose equipment will interfere with work, hinder movement. The length of the jacket should be sufficient to overlap the trousers by at least 20 cm. The length of the trousers is considered appropriate if they cover the shoes; there should be no cuffs on the legs.

- The ends of the sleeves should be firmly attached to the wrists.

- On pockets - both overhead and in the seams - the presence of velcro, valves is required to avoid sparks getting inside.

- It is desirable that there were holes for air exchange on the clothes, which is especially true for summer models.

- Clasps must be hidden so that the strip of material protects the buttons from heat and sparks of fire. For added protection, padded inserts around the elbows and knees are encouraged.

- Every time before starting work, clothes must be carefully inspected: the presence of stains of grease, oils, other combustible materials is unacceptable. And also there should be no tears in the fabric, scuffs, torn edges.

Even small defects can create traumatic situations and lead to burns. Do not allow lighters, paper, or other flammable items to be in your pockets.

The following video provides an overview of the welding suit.

The comment was sent successfully.