What is workwear and what is it like?

At present, it is difficult to find areas of industry, service, trade, construction, in which workers, specialists and even engineering and technical personnel would be at their workplace in ordinary everyday attire. Employers strive to provide their employees with the same clothing, which, by the way, in industrial production and construction is mandatory in accordance with the requirements of industrial safety, labor protection and industrial safety rules. This is called workwear or workwear. In medicine, the service industry and in some other enterprises, work clothes are called uniforms. But this does not change the essence.

What it is?

Special-purpose clothing was originally created for those professions where workers were exposed in the course of work to a high risk of injury and other harm to health, up to and including death. These professions included, for example, a firefighter, steelmaker, miner, metalworker, chemical industry workers.

Later, all enterprises with "hot", "dusty", gas-polluted and repair shops began to refer to industries with harmful and hazardous working conditions, where workers were provided with overalls. In the context of the development of industrial and agro-technical complexes with high-tech processes and complex equipment, the number of professions requiring employers to provide their personnel with special-purpose clothing or work clothing has been regularly growing every year.

Currently workers in almost all industrial enterprises must be supplied with special or work clothing when applying for work. In some cases - several types of it, including separately for the cold and warm periods of the year (sets of winter and summer clothes). In many cases, workwear is both a protective suit and work clothing. Often, work suits are used in everyday life, for example, they are used by gardeners, tourists, fishing and travel lovers.

For each profession, the requirements for workwear are regulated separately by the TR CU document (Technical Regulations of the Customs Union).

Primary requirements

According to TR CU No. 019 of 2011, special-purpose clothing must meet the following basic requirements:

- to provide a person with the necessary level of protection from the harmful or dangerous effects of production;

- meet hygiene standards;

- be environmentally friendly, do not cause itching of the skin;

- have a loose fit, so as not to restrict the employee in movements, but at the same time not deprive him of his comfort and safety;

- to be functional, to have everything you need for the normal performance of your job duties (pockets, straps, carabiners, and so on);

- should not get wet from the rain (if intended for outdoor work);

- have a dirt-repellent property and are easy to clean (wash off);

- be made from durable fabric;

- have a quality certificate.

Regular work clothing in general should meet the same requirements as special work clothes, except for a few factors. For example, indoor workers do not need a waterproof suit or thick, durable fabric.Previously, a work suit for many professions was sewn from cotton fabric, which met many of the requirements listed above. Now such material in its pure form is rarely used for sewing work clothes.

What is included?

If we talk only about special-purpose clothing, then it designed to protect employees from aggressive external factorssuch as high temperature, low temperature, open fire, sparks of hot metal, chemical and poisonous substances, oil vapors and poisonous gases, moisture, dirt, radiation. And this list is far from definitive.

Depending on the profession for which this or that workwear is intended, its summer set may include the following products:

- trousers, overalls or semi-overalls made of waterproof (sometimes non-burnable, like welders or firefighters) material;

- a suit or summer jacket made of the same material as the trousers;

- protective footwear (boots, boots, boots), which can be with reinforced (metal inserts, like those of builders or foundry workers) toes that protect the worker's toes from injury in the event of heavy objects falling;

- gloves, mittens (welders, firefighters and foundry workers must have leggings);

- protective glasses;

- bathrobes;

- T-shirt;

- hats (helmets or helmets).

For some works, earplugs or headphones are added to the kit if there is industrial noise, as well as respirators and even a gas mask (for example, painting, plumbing work). When work is carried out in conditions of poor visibility (for example, at night or in thick fog), be sure to wear signal vests over normal work clothes. In rainy weather, an accessory such as a raincoat will also come in handy.

For the winter period, in addition to warmed options for a suit, shoes and gloves, underwear, a hat, a winter jacket, and a sweatshirt under the suit are added.

Species overview

As for the classification of workwear, there are many features by which you can group its models. But still it is worth dwelling on the main ones. Special-purpose clothing is mainly categorized by purpose and seasonal type.

By appointment

The equipment of workers of various professions has a fairly wide range of differences. It depends on the types of possible threats from external factors in the performance of their duties. For example, the uniform of a welder or firefighter must be fire-resistant, therefore, in the manufacture of outerwear for them, refractory material is used. For electricians, a special set of equipment was created, which without fail includes an antistatic protective T-shirt and an electric arc protection suit.

Of course The above items of equipment are not required for such professions as a car service mechanic or a gardener who spends his day in the garden. The latter will need a special suit for disinfecting the premises of greenhouses, greenhouses, seed storage and spraying shrubs and trees.

Potential threats, in turn, are subdivided into the following subspecies:

- thermal (implying hazards from both high and low temperatures);

- electrical (associated with the danger of electric shock and high voltage);

- chemical and biological (work in conditions of risk of chemical poisoning, burns, as well as biological contamination);

- sound (work in high noise conditions).

In addition, within the framework of the classification of equipment by purpose, there are also varieties of personal protective equipment (PPE), the completeness of which depends on which parts of the worker's body surface should be protected. For example, the work of a slinger carries the risk of injury to the hands, head, legs, therefore a helmet, shoes reinforced with metal inserts and durable gloves are mandatory elements of this specialist's equipment.

Exactly the same importance is attached to the safety glasses for the carpenter or turner in their clothes when performing their tasks in the workplace while using the machine tools.

By season

Specialists whose workplace is not limited only to office or industrial interior premises, but also provides for outdoor activities (or even the whole day of work is performed outdoors), should be issued with two sets of work clothes: for the summer and winter seasons.

A modern summer kit should create a feeling of comfort for the employee when performing work even in hot weather, but at the same time have protective properties. Sometimes it makes sense to provide workers with large summer clothes, so that, for example, in high humidity and stuffiness, good ventilation of air between the body and the fabric is created.

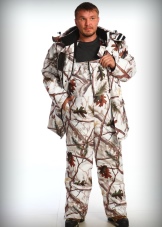

Sets of winter overalls are designed to protect a person from hypothermia in freezing temperatures. They should not be blown by the winds, get wet from atmospheric precipitation and are equipped with an insulated lining. Winter work clothes are divided into five classes of protection, of which the most extreme is the 5th class, corresponding to the most severe climatic zone of our country - the Far North.

This garment must withstand temperatures as low as -50 degrees Celsius and strong gusts of wind. For this class, the set of winter working ammunition without fail includes a warm jacket and sheepskin coat, felt boots, thermal underwear, a hat, a quilted jacket and warm pants.

For winter sets, mandatory elements of outerwear are a hood with insulation and a collar, as well as a windproof insert, an insulated belt and cuffs on the sleeves and on the bottom of the jacket, made of jersey. For classes 1 and 2 (the mildest climatic zones), the hood is made without insulation.

By color

Many employers now strive to dress their employees stylishly. True, in the pursuit of aesthetics, the main purpose of work clothes is often forgotten - protective. Even at one enterprise, there is a certain division between the form of work clothes, for example, engineering and technical personnel and ordinary workers of different departments, including by color.

As for the color of overalls, there are no legalized solutions in this regard, except for instructions on protective helmets at construction sites and industrial enterprises (an engineer and technical worker should have a helmet only white, and a worker should have any other color, even red or black). That's why it is quite justified if enterprises order work clothes of several models and colors, so that you can visually distinguish an employee of the repair shop, dressed, for example, in a green overalls, from a janitor, dressed in an orange suit.

Especially popular are gray and blue overalls with reflective stripes on the jacket and trousers.

Materials (edit)

For the manufacture of summer sets, as mentioned above, cotton was previously used. They use it now, but quite rarely in its pure form. Currently, mainly blended fabrics are used, consisting of a part of cotton and various chemical fibers. In addition, denim is a fairly common material used for the manufacture of workwear, but also mainly with some additives, including protective properties.

High-quality cotton fabric (for example, satin, chintz, flannel, calico and others) is used in sewing work clothes for medical institutions, food and hotel enterprises. Differs in high hygiene, softness and durability.

Often used for sewing work suits fabrics from a mixture of flax and cotton. Additionally, such material is subjected to special processing in order to improve its practicality.

Impregnations can improve properties such as moisture absorption, fire resistance, dirt and water resistance.

However, for workwear intended for welders, builders, firefighters and high-altitude installers, cotton materials are suitable only as summer T-shirts, which are put under their protective overalls to wick away sweat from the body. Suits for these specialists are usually sewn from tarpaulin with various protective impregnations: from rain, fire, sparks, wind.

The requirements for materials for workwear are as follows:

- wear resistance;

- complete preservation of protective properties and quality even during long-term storage;

- material properties should not be lost during cleaning, washing and disinfection;

- even coarse clothing should not cause any damage to human skin.

Popular manufacturers

Beautiful work clothes are made at the sewing production "Nika". It has existed since 2004 in Nizhny Novgorod and Dzerzhinsk. Here you can order suits with a company logo or your own brand name. Now branded workwear is a fairly common phenomenon, a kind of advertising for production or services.

The "Patriot" company carries out sewing of work and special clothes for workers of any branches of the national economy. This manufacturer has in its staff only qualified employees with specialized education who are able to create high-quality garments of any complexity. There are offices in Moscow, Voronezh and Sudzha.

Nuances of choice

When choosing workwear for an industrial enterprise or a company in another direction, you should adhere to the basic criteria and necessary rules.

- Each industry has its own technical conditions established for workwear. Therefore, you should look for or order such equipment for your employees, which will correspond to the industry specifications.

- Products must be made of high-quality material that will last the entire normalized period.

- If there are many workshops and departments in the production, it is better to order or choose different colors of overalls - for each workshop or department. This makes it easier to organize and control the workflow.

- For workers serving outdoor spaces or roads, it is necessary to choose suits with reflective stripes. This will prevent many injuries and accidents.

- You need to take care of the appearance of the clothes and their functionality. Having a good cut and lots of pockets is a sign of style and practicality. And the workers themselves will be happy with their fashionable clothes.

When choosing a winter set, special attention is paid to the material of its manufacture. - it must be sufficiently plastic and soft. Otherwise, it will be quite difficult to work in it in the cold. Certain types of work in tight clothing is very problematic. Summer clothing should be hygroscopic and breathable.

Care Tips

Despite the fact that the law obliges the employer to ensure the storage and maintenance of overalls, it should be noted that the employees themselves must know where and in what condition work clothes, footwear and personal PPE should be stored. Not only safety at work depends on this, but also the health, and even the life of the employee.

Here are some tips.

- Since dirty clothes and shoes are unlikely to protect the worker well from harmful production factors and the environment, therefore, they should always be cleaned or washed after any contamination.

- Work shoes must be washed not only outside but also inside on weekends, and then left to dry. Dry shoes periodically need to be treated inside with antifungal drugs in order to avoid the growth of fungus and infection of the feet.

- PPE should be periodically disinfected and decontaminated in the chambers provided for this at the enterprise.

- Personal work clothing should be stored in the dressing room and washed and cleaned in the industrial laundry. Never wear dirty overalls home.

The comment was sent successfully.