All about the snow blower gearbox

Nowadays, snow removal equipment is in great demand. Snowblowers are notable for their reasonable price and high efficiency in clearing the roadway or the area around the house. But screw, rotary or rotary snow blowers, like any other units, have mechanisms and parts that eventually become unusable and need to be replaced. For stable operation and prolongation of the service life of machine mechanisms, timely and correct maintenance is recommended. In this article, we will talk about the snow blower gearbox, its design, types and some important points for caring for it.

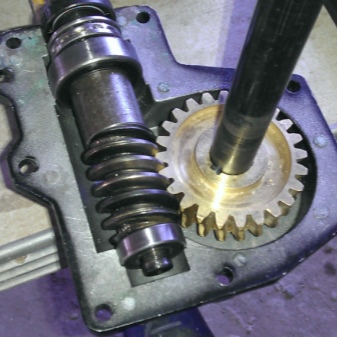

How the snow blower gearbox works

The gearbox is a very important element in the snow blower, because it receives the torque generated by the engine, and the CV joint - the hinge of equal angular velocities - transfers it to the working parts of the machine (auger and rotor). The basis of the gearbox is a gear. The auger mechanism of the snow blower is fixed on the surface of the shaft with several shear bolts, which are the first protection system of the engine, since they can only be cut off if urgent repairs are required. No vibration, no mechanical effort, no attempts to unscrew them will lead to any result - only cutting.

The gear and other parts are located in the protective housing of the assembly. In household snow blowers, it is made from an alloy of silicon and aluminum, and the body structure is in two parts, bolted together.

Gearbox types

Snow blower gearboxes are of the following types.

- Serviced. It can be disassembled by yourself to refill grease or replace worn parts. The elements of this mechanism are made of bronze, which explains their slow wear. This type of gearbox is rated as more reliable - it can last for a very long time with proper care. This is the mechanism used in European, Japanese and American models of snow blowers.

- Unattended. This gearbox is maintenance-free, but cannot be disassembled or repaired. The term of use of such mechanisms is limited. If the gearbox is broken, then you should buy and install a new one. There are no other options here. Inexpensive Chinese and Korean models are equipped with this type of gearboxes.

Gear selection

The gear is an important part of the gearbox and can be made from a variety of materials. The most common option in household machines is a 19 mm diameter bronze gear with 20 teeth. Larger professional snow blowers use a 25 mm diameter gear with 41 teeth.

If an unexpected blockage of the auger occurs, the gear can take on the resulting load of the mechanism and protect the motor. The bronze gear belongs to consumables, therefore, if it breaks down, it is replaced with a similar one with the same diameter and number of teeth.

How to choose the right lubricant

In order for the moving mechanisms of the gearbox to work perfectly, they need high-quality lubrication. Snow blower manufacturers advise using only gear oils. Litol and similar inexpensive fluids cannot be used as a lubricant, as they do not provide adequate protection and freeze at low subzero temperatures. The lubricant should have the following properties.

- Be frost resistant. This is the most important quality, because snow throwers have to work at times at very low temperatures. The structure of the grease must be maintained under severe frost.

- Have the necessary fluidity. This means that the oil must quickly enter all the grooves and holes, since the lubrication of the rubbing parts occurs continuously.

- Be viscous. The oil must have the thickness required for a particular device in order to cover the working mechanisms with a strong film.

How to quickly remove the gearbox

For a scheduled lubricant change, remove the gearbox from the snow thrower. The algorithm for this process consists of several simple operations.

- Position the snow blower level and still.

- Remove the plastic protectors from the belts and the auger cable that goes to the drive.

- Unscrew the screws behind the "volute" (round body) to eject the snow.

- Remove the belt that goes from the pulley to the auger. Carefully pry it off with a screwdriver.

- Unscrew the screws securing the auger shaft.

- Turn the "snail" so that it is set in its normal position until it clicks. Carefully remove the auger mechanism and impeller.

- Remove the shear bolts from the auger and disassemble the shaft.

Gearbox disassembly process

To easily replace the lubricant in the removed gearbox, you need to disassemble it according to the rules. This requires the following steps:

- clamp one part of the shaft in a vice (the one on which the gearbox is located);

- unscrew the six bolts that fix the connection of the gearbox parts to each other;

- with a hammer, do not knock very hard on the gearbox housing so that it is easier to separate into two parts.

How to fill in new grease

After you have removed the gearbox and divided the housing into two parts, thoroughly rinse its inner space from traces of old grease. For this purpose, it is better to disassemble the mechanism and put all the parts in a container with gasoline for several hours or a day. After the specified time, all parts must be pulled out and dried well with a rag. Then the gearbox must be assembled and carefully put in its original place in the snow blower. Then, without replacing the cover of the protective case, unscrew the union and pour a new high-quality grease into the gearbox with a large syringe.

To get new oil into all the grooves of the mechanism and lubricate all the parts, start the engine of the snow blower, raise its front part and press the auger drive lever several times sharply.

Operating tips

To extend the life of the snow thrower gearbox, you should carefully read the advice of experienced craftsmen.

- Always use good quality gear oil for lubrication. If the device is lubricated with semi-synthetic analogs, the mechanism will quickly fail.

- Take ten minute breaks after an hour of snow blower work. This is necessary so that the gearbox does not heat up too much and does not wear out prematurely.

- Flush the knot regularly. Even when filling with high-quality oil, carbon deposits can accumulate on the walls, interfering with the ideal operation of the mechanism. If you use your snow blower regularly, you should flush it every two weeks.

- Be careful when squeezing the auger drive lever. After all, any push of the lever stretches the drive cable. Therefore, pushing the wire lever should only be used when absolutely necessary.

- Do not allow oil to leak out of the gear housing. Check and replace all oil seals in time.

- Always inspect the snow carefully to ensure that no foreign matter gets inside the snow blower. They can damage the gearbox.

The gearbox of a snow blower is the most important mechanism after the engine in the operation of the entire system. Always read the instruction manual carefully before using the snow blower.After all, with a careful attitude to the condition of the gearbox, your machine will work much longer without breakdowns.

For information on how to replace the gear in the snow blower gearbox, see the video below.

The comment was sent successfully.