Subtleties of repairing snow blowers

A snow blower is a special device that removes snow on surfaces. By driving a snow blower, you can grab, grind and throw snow over a long distance. The snowplow has special devices in its design, thanks to which you can easily and efficiently carry out cleaning.

Construction of snowblowers

To learn how a snow blower works, you must first understand what it is made of. The main elements are a few details.

An engine that has a 4-stroke motor. These engines are pre-adapted for winter frosts with temperatures of -31 degrees. In most cases, motors from famous companies such as Briggs & Stratton, Tecumseh are in demand.

If the snow blower does not have an air filter, then this is a characteristic feature of a winter engine, since the filter can become clogged with snow, freeze up and turn into a plug. The snowblower must not be operated all year round, as the device can fail not only from winter dust, but also from ordinary dust. A sleeve motor is considered maintainable; it is installed on professional snow blowers.

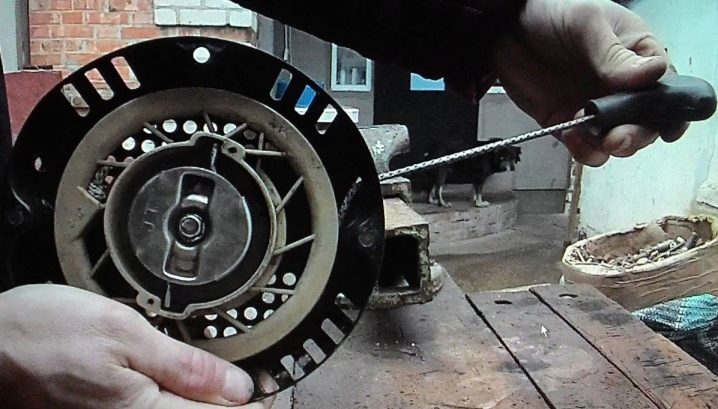

The petrol model has a hand starter with a lanyard. Low-power cars have a manual start, while more powerful ones have an electric starter. The electric starter itself has two types - powered by a household electrical network and from an on-board battery. The first option can be started by connecting the motor to an outlet and pressing a button. To start a cold engine, you need an electric starter.

Snow blowers can be self-propelled and non-self-propelled. Often a manual transmission is installed on snowblowers. Some models have CVT and hydrostatic transmissions with different numbers of speeds. Snow blowers have 5 gears in the front and one gear in the rear.

The edge of the augers can be of two shapes: serrated and smooth.

The 2-stage snow blower has a strong, powerful auger. Its function is to crush adhering lumps of snow; and it can also push snow towards the center of the bucket where the snow diverts to the impeller. The impeller itself will not be able to crush the snow. Its task is to set the speed for the incoming snow. Snow is thrown aside.

In single-stage types, the screws can touch the ground during rotation, so they are made of metal or rubber plastic. Thanks to the rubber-plastic material, the auger will easily withstand collisions with pebbles; will not break or deform. And the auger made of metal can break in this case.

The tires are branded with tread patterns X and V. These tires have good grip.

The outlet chute has two options: metal and plastic. Metal has practically no vibration. It is more durable and more accurate for throwing snow. But the plastic chute prevents the snow from sticking to the device, it is much cheaper and will not be able to rust.

The gearbox can transfer torque from the shaft to the augers. Cross-country skis provide good glide. They support the front of the device. They can be adjusted in height by setting the degree of snow removal. There are reversible skis that can be simply turned over when worn.The scoring blade, which is located at the bottom of the bucket, must not touch the ground.

Snow throwers have chassis with wheels or tracks. Wheeled wheels move without turning on the engine. The tracks are more resistant to ice and slopes. The frame can include circular cross-section tubes. There are brands with rectangular tubes, they can provide the strength of the device.

The snow blowers also have the necessary headlights, which are charged using an on-board generator. All snow blowers have a control program with which you can adjust the engine speed, engage or disengage gear and wheel drive, you can adjust the height, direct the discharge of snow, and so on.

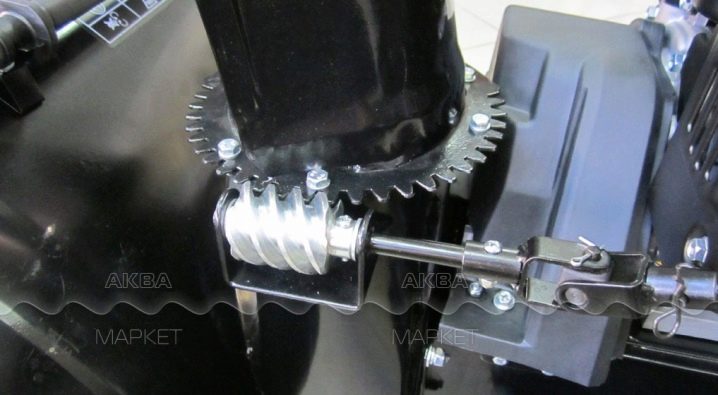

To set the direction, you need to rotate the outlet chute. Ordinary models have a handle for this. You can often find a worm gear. To make a turn, you need to turn a special handle.

It is very rare to find snow blowers that have an electrically driven directional design. Professional machines have levers on the panel. With the help of such a lever, you can change the height without interrupting the movement.

Frequent malfunctions

Improper use can cause the snow blower to break. Also, the device contains parts that can fail as a result of dirt and rust. Before turning on the device, you need to read the instructions well.

Highlight some of the major breakdowns in the snowplow.

The most common problem is broken keys, i.e. shear bolts. With the help of them, the screw parts are strengthened. The bolt material is soft metal. If the snow blower accidentally hits any obstacle, the bolts will shear off and the shaft of the mechanism will stop. The dowels are a necessary consumable. They should be kept in stock by every owner of a snow blower.

If you save on the purchase of shear bolts, replacing them with ordinary bolts, then the snow blower can completely fail. In this case, you will have to purchase a new device. Shear bolts can serve a safety purpose, that is, they can protect the main elements - this is the engine and the rotor structure.

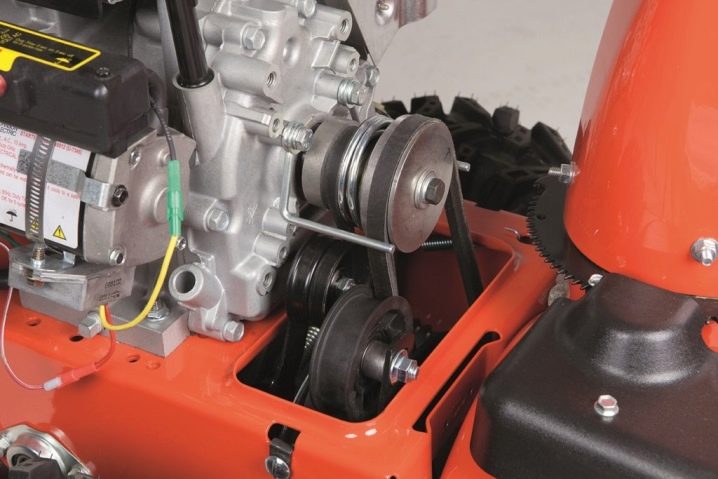

Among the breakdowns, there is also a failure of the belts to work. When purchasing a snow blower, you can purchase a replacement drive belt. If the snow blower is constantly clearing the snow, the belt itself can become very worn out and cause it to break. Belts can go to wheelbases, and can be driven for auger construction.

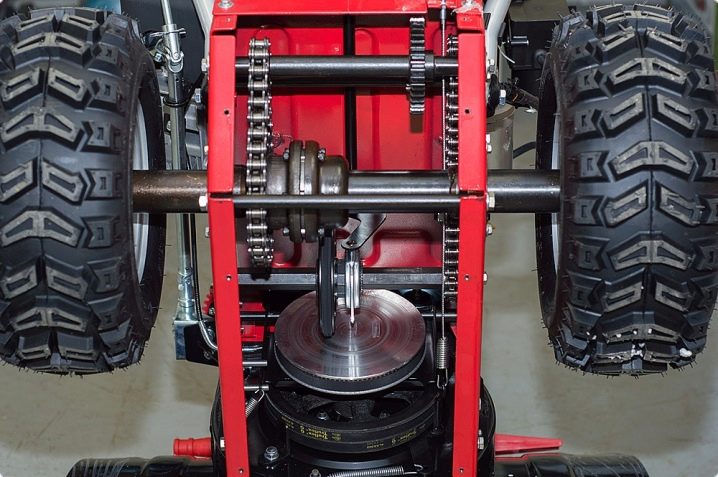

Broken friction discs are another common problem. They can drive wheels. There is a special friction wheel, it is pressed against the disc. When it starts to rotate, it can transmit motion to the wheels using gears. If the load on the wheel structure is exceeded, the entire friction ring may fail, and the steel friction wheel may damage the soft structure of the aluminum rim.

For the most part, these breakdowns lead to the fact that the snow blower will not start and will not function normally. In order for the device to work, you must either replace the components or make a complete repair.

Repair

Some components and work units can break, and as a result, different brands of snow blower can malfunction. The device has its own individual characteristics and design. But repairs will be the same for all models of snow blowers.

To make home repairs, you need to follow some tips. There are snowblowers whose discharge chute does not work well, that is, cannot throw snow. To repair it, you must:

- check if the safety bolts are cut off;

- disconnect the bucket on the frame device;

- pull out the gearbox, open and check the worm on the shaft;

- if the problem lies in the shaft, then you need to buy new worm gear pairs and strengthen them.

If the engine squeaks during work, or the engine cannot start, then the problem lies in the carburetor. To fix it, you need to perform several steps.

- Remove the crankcase breather tube and check for vacuum.

- It is necessary to find the screws for regulating the composition of the mixture and screw them in until the engine starts to sound.

- If the engine is actively working, then you need to stop turning the screws, because the engine may stall.

- It is necessary to unscrew the screws 1 full turn back. The motor of the device will function well and will not make unnecessary sounds.

If there are problems with the rotation of the auger, then the reasons may be: cutting of the protective bolts, low tension, a broken gearbox of the auger apparatus. If the auger does not rotate, then the shear bolts must be replaced. For this you need:

- match the hole on the auger and the hole on the shaft;

- put a bolt in it and secure with nuts.

If the snow blower is not good at throwing snow, then you need to first check the stability of the auger drive. Perhaps the pinch roller with the torso attached to it is not pressing well on the drive belt. The cable may break and stop the snow blower screw. In this case, you just need to replace it. The cable must be removed from the handle of the mechanism, and then disconnected from the pressure roller.

If the wheels do not move, then this means that the friction ring has deteriorated. So that this ring does not deteriorate, it is necessary, after all work, to carry out prophylaxis to cleanse dirt and snow. Otherwise, the ring will rust, crumble, and the clutch will stop working. If the ring and wheels are worn out, then you need to completely replace the clutch.

To change the rubber ring, you need to unscrew four bolts, remove the worn out element, and insert a new part into the disc. After that, you can tighten the fasteners.

In order to repair the friction disc with your own hands, you need:

- place the snow blower in a position convenient for carrying out maintenance;

- unscrew the bolts and move the bottom cover;

- remove the wheels;

- pull the side support flanges off the frame, unscrew 3 bolts, remove the flanges from the bearing;

- it is necessary to place the hexagonal axis on the left side to remove the friction disc from the center;

- if the friction discs have rubber rings, then they must be replaced;

- if the disks have soldered rubber, then you need to unscrew the disk from the bearing fastener assembly;

- when it will be necessary to install the disc, the bearing stops must enter the guide of the gear shift rod, the disc must move easily along the shaft;

- adjust the clutch.

If the engine cannot start, then it is necessary to inspect the compression of the unit using a compressor. The compressor should read between 7 and 10 atmospheres.

If the problem is with the starter, then the cord must be replaced first. The starter has a return mechanism and a hole where you need to thread the cord. To make the starter work, you need to cut out an old cord, untie a knot of cord inside the starter that can withstand it. You need to rotate the device counterclockwise and make 8 full revolutions. To block the return movement of the device, you need to insert a screwdriver between the ribs. The cord must be passed through the hole, and a strong knot must be tied at its ends. It is necessary to remove the screwdriver with which the cord was held. The recoil device itself will be able to wind the lace on the spool.

If the snowblower gives out bad vibration, then the engine mounts should be checked and tightened if necessary.

If the gearbox does not work well, then you need to replace the gear (it is located inside the gearbox).The gear causes the mechanism to malfunction, as it constantly wears out, so you just need to purchase a new part and attach it.

At the end of winter, drain the oil and fuel from the snow blower before removing it. Then wipe the entire apparatus with a dry cloth and leave it in a dry place.

Snow blowers are good helpers for people in winter. Functionality and life will depend on the proper use of this device. The main thing is to properly handle this device and not to allow any breakdowns and repairs.

You can get acquainted with some of the intricacies of repairing snow blowers in the next video.

The comment was sent successfully.