Features of semicircular benches

There must be a recreation area in the garden or on the personal plot. A semicircular bench can be an original solution here. You can do it yourself if you have free time, tools and simple building materials.

What are they?

You can also buy a bench in the store. But if you want originality, then it is better to do it yourself. There are many different options. They are an integral part of landscape design. Benches perform several functions at once:

- complement the landscape arrangement of the personal plot;

- are a full-fledged place for rest and relaxation after performing any work on the site;

- emphasize the individuality of the owners, "tell" others about his tastes and preferences in the interior.

There are several types of benches. Of course, they may differ from each other in shape, but the article deals specifically with semicircular benches. In turn, they are subdivided into:

- semicircular;

- U-shaped;

- L-shaped.

Differences in material of manufacture should be noted. It can be: wood, plastic, metal, concrete, natural stone. Products can be painted in different colors, have an original finish. And also the differences lie in the capacity: the most popular models are 2, 3 and 4-seater. Benches can be portable or stationary.

The most popular models are wooden benches, for the manufacture of which various woods are used. Some elements can be forged. Much less often, plastic is used for the manufacture of benches, since it is reasonably considered a short-lived material that is unstable to temperature extremes, sunlight and mechanical stress.

Tools and materials

Before proceeding directly to the manufacture of a bench, it is necessary to prepare materials and tools that will be useful during work. Materials need to be prepared depending on the project of the future structure.

Consider what is required to make a classic semicircular bench made of wood and metal elements.

- Legs in the amount of 6 pieces. It is better if their dimensions correspond to the dimensions of 5x7x50 cm.

- Longitudinal slats - 4 pieces (2 rear and 2 front). For the near edge, the parameters should be as follows: 4x4x80 cm.The rear dimensions are 4x4x100 cm.

- Cross bar - 3 pieces (4x4x40 cm).

- Galvanized metal corners: 14 pieces 4x4 cm, and another 6 pieces 5x7 cm.

- Identical boards - 34 pieces. The size is 2x5x50 cm. They will be used directly for the manufacture of the seat.

If you wish, you can make a back for a semicircular bench, but this will require additional materials. And also it is necessary to prepare: paint, varnish, moisture-proof treatment (if necessary).

From tools in the manufacturing process can come in handy: saw, nails, screws, screwdriver, sandpaper.

How to do it yourself?

Making a street bench for a summer residence with your own hands is quite simple. The process consists of important stages that are interconnected with each other.

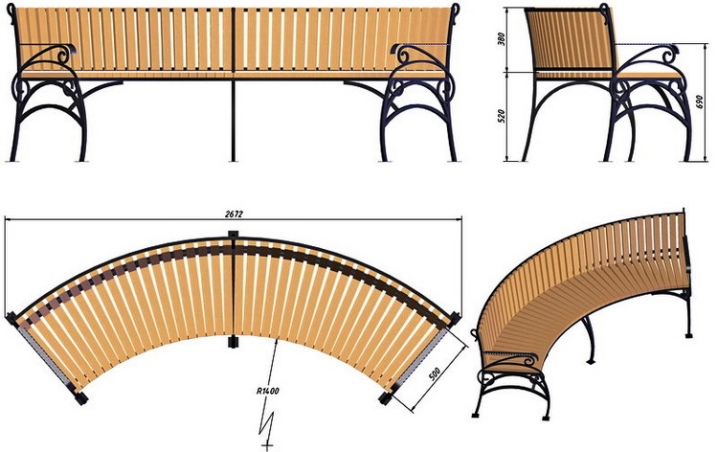

First, you need to draw up a project that will have to be followed during the entire manufacturing process. As an example, we should take a very interesting model - an L-shaped bench. Its advantage is that if you make two such benches, you get a semicircle, and if four, then a circle (a full-fledged resting place for a large company).

A country bench will have the following parameters: 2x0.5x0.5 meters (this corresponds to the dimensions of those parts that were described in the previous section). Then you can proceed to the preparatory work. They consist in the fact that all the boards need to be processed with sandpaper for smoothness. The corners and edges of the cuts must be smoothed out with a rasp.

The next stage is painting. So that in the future the product does not fade in the sun and does not deteriorate under the influence of moisture, wooden parts must be treated with special compounds. They can be purchased at the store. When the treatment is dry, you can varnish or paint the boards in the desired color.

The next steps are best done the next day, when the paint is completely dry. So, you need to take a series of steps one by one.

- Assemble the product frame. It consists of legs, longitudinal strips and transverse bars. It is noteworthy that you need to collect exactly so that you get a bend. It is necessary to connect the parts using iron corners.

- Next, you need to pin the planks, having built a place to sit.

- At the final stage, if necessary, you can touch up unpainted areas with a small brush.

The radius bench is almost complete. Now it needs to be cleaned of dust with a damp cloth and installed in the right place. Decor elements can be added as desired. Their design is entirely up to individual preferences.

For more information on what a semicircular bench is, see the video below.

The comment was sent successfully.