Features of metal benches

A good and beautiful bench does not have to be made of natural wood only. Very sturdy, attractive and practical designs are obtained from metal. In this article, we will learn more about the features of metal benches.

Advantages and disadvantages

A bench made of metal is the most reliable and durable thing. Today, in many summer cottages and garden plots, you can find similar products. They are in many ways superior to standard wooden options, demonstrating higher practicality and unpretentiousness.

The popularity of metal benches is due to the many positive characteristics that they have.

- The main advantage of the products under consideration lies in their strength and resistance to mechanical damage. It is incredibly difficult to spoil, break or deform such a structure. Under the influence of precipitation and temperature changes, the metal bench will not lose its visual appeal, it will become less strong. Of course, we are talking about well-groomed versions, made according to all the rules.

- A metal bench can serve for many years. By itself, this material is designed for many years of operation. In this capacity, it is impractical to compare wooden options with metal structures.

- Metal can be easily combined with other materials. Most often, there are models in which a metal frame is provided, and the back and seat are made of wood. The result is both reliable and beautiful and very comfortable designs.

- Metal benches can have a very unusual, elegant design. At summer cottages and adjoining grounds, you can often find truly amazing designs, from which it is difficult to take your eyes off. A metal bench can have all sorts of decorative elements, graceful lines and sophisticated features. Such a detail will effectively complement the local area.

- Garden and home furniture made of any type of metal is environmentally friendly. You can use such products without worrying about your health. Metal structures do not emit pungent odors and do not cause allergic reactions.

- A metal bench is an absolutely fireproof design. Moreover, in the event of ignition, the metal will not support the flame, actively spreading it. The same cannot be said for models constructed from wood.

As you can see, metal benches have a lot of advantages. However, it was not without its drawbacks, some of which are quite serious. Let's get acquainted with them.

- In the manufacture of metal benches are more difficult and capricious. It is much easier to work with the same tree, and it takes less time. When making a bench from metal, the master must competently use the welding machine, and not all users have such skills.

- Metal benches are often very heavy. It can be problematic to move such structures from one place to another. If you do not plan to carry or transport a similar product in the future, then this will not be a problem.

- Sitting on a bench made entirely of metal is not always comfortable. This is especially true for the hot summer season.During such periods, the metal seat heats up very quickly and strongly, which leads to very unpleasant sensations. In cold seasons, sitting on such a bench is also uncomfortable, because the seat becomes unnecessarily cold.

- Making your own or buying a ready-made metal bench can cost a tidy sum. This is especially true when people pick up a very beautiful, original model, decorated with artistic forging. The same wooden or plastic types of benches are much cheaper.

- The metal bench will have to be regularly treated with special compounds that will protect it from corrosion. The only exceptions are stainless steel products.

Varieties

There are many different types of metal benches. Each of them has its own distinctive features and characteristics. Let's get to know them better.

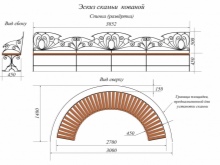

Solid forged

Today, solid-forged garden benches are very popular. We are talking about structures that consist only of metal rods. As a rule, these models are characterized by a relatively low weight, due to which they can be easily transferred from one place to another, if necessary. The solid-forged bench is extremely easy to care for, so it retains its attractive appearance for many years.

This design is an excellent solution for a summer residence. A beautifully executed solid-forged street bench can easily become an elegant decoration for landscaping. Fortunately, you can do it yourself or find a suitable option in the store - the range of such products is huge.

Combined

The name of these benches speaks for itself. They are made from a combination of different materials. In this case, most often we are talking about such structures in which only the frame is constructed from high-strength metal, and the seat with a backrest is made of properly prepared natural wood of any species. Benches of this type are rightfully recognized as one of the most popular. They are installed not only in the yard or in the garden, but also in living quarters, since they are great for home.

Combined benches are further subdivided into several subtypes. They can be of different shapes and sizes. Often there are not only standard rectangular, but also angular options, as well as more unusual specimens in the shape of the letter "P".

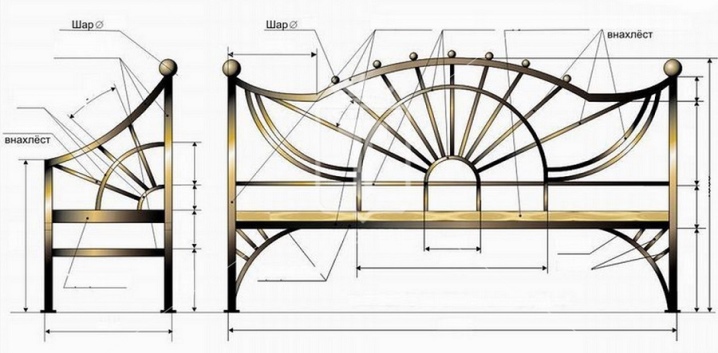

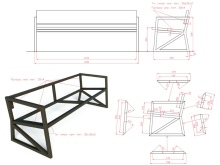

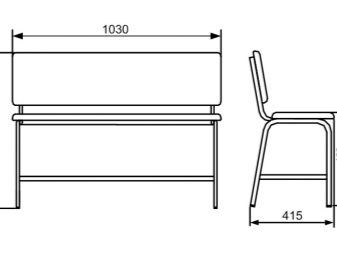

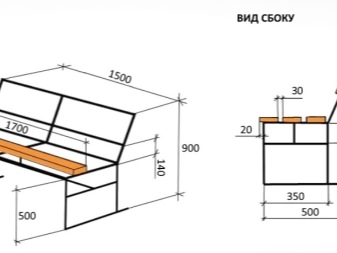

Drawings and dimensions

Metal benches are not only bought in specialized stores, but also made by hand.

If a decision is made to design a high-quality homemade product, you must first draw up a detailed plan and a drawing of the future product.

It is quite possible to prepare a project and a diagram of a metal bench on your own, there is nothing complicated about it. However, many people prefer not to do such experiments and choose ready-made projects. Thus, it is possible to avoid many mistakes and shortcomings during the workflow for creating a shop.

It is important to take into account the fact that the dimensional parameters of the future metal structure are selected strictly individually. There are a few rules that it is advisable to take into account before starting work:

- the length of the bench must be determined at the rate of 0.6 m per person;

- the minimum width of the product should not exceed 30 cm;

- the back must have a height exceeding 30 cm;

- the angle between the seat and the back can be from 105 to 120 degrees, so that it is comfortable to sit on the bench;

- the bench height parameter should be calculated in accordance with the length of the tibia, in most cases it is 38-45 cm.

If the bench is higher than 45 cm, then the legs of the people sitting on it will hang from it. If this parameter is less than 30 cm, then the knees will have to be bent at an acute angle, which has a bad effect on blood circulation and leads to an unpleasant sensation in the legs.

All the dimensional indicators with which you want to make a metal bench must be entered into the drawing of the future homemade product. Having at hand a detailed work plan, it will be much easier for the master to make a shop.

Tools and materials

In order to build a high-quality iron bench with your own hands, the master will definitely need to stock up on all the necessary materials and tools:

- profiled pipes (the diameter must be selected in accordance with the prepared drawings of the future homemade product, as well as the features of the operation of your structure);

- boards from which the master will construct the back and seat of the bench;

- high-quality welding machine;

- electrodes for the welding machine (3 mm);

- grinder or hacksaw for metalwork;

- discs designed specifically for grinders and metal work;

- drill;

- file;

- level;

- roulette;

- plane;

- metal paint;

- paint for wood;

- nuts and bolts;

- pliers.

To assemble the frame of a future homemade product, you will need either shaped pipes or forged parts. It all depends on what kind of structure you have planned to design.

How to make a bench?

When all the accessories and materials are ready, it's time to move on directly to making a high-quality and beautiful bench with your own hands. Let's analyze in stages how to do it correctly.

Frame

The first thing that the master will need to do is to build a high-quality frame of the future product. Let's see how to prepare it.

- To make a base for the seat, you will need to connect the elements from the profile pipe in the shape of the letter "P".

- You need to prepare the details for the back. The upper half will need to be bent under a radius of 300-400 mm.

- By means of a welding machine, it is necessary to attach the backrest parts to the U-shaped base. It is advisable to attach the back to the seat at an obtuse angle. To do this, the bottom half of the parts can be folded slightly.

- All the prepared elements of the future bench will need to be connected by means of long pipe sections. 2 of them need to be attached horizontally, and 2 - vertically. The structure will be more rigid if additional components are welded between its legs. Be sure to strengthen the bench with diagonal elements.

- In the lower half of the metal frame base, as well as on the side and in the back area, you can additionally weld forged parts in the form of floral ornaments or graceful patterns.

- It is necessary to weld special "patches" to the supporting legs of the structure so that the bench is more stable while on the ground.

- The metal components of the product will need to be coated with a primer mixture and covered with enamel.

Seat and backrest

After you make the frame base of the metal bench for the summer cottage, it is advisable to proceed to the installation of the seat and back. Let's see how to do this.

- Pre-prepared and thoroughly dried boards or blocks will need to be sawn in accordance with the dimensions indicated in the drawings.

- Wooden parts must be processed with an electric plane, sanded. After scrupulous cleaning of wood elements, they will need to be coated with protective solutions, then painted with decorative enamels.

- It will be necessary to attach 50x50 mm bars to the shorter parts of the metal frame in the area of the seat and backrest. It is best to secure them with screws, washers and nuts.

- Further, by means of self-tapping screws, you will need to attach wood components for the seat and back of the bench to the bars. In order for the screw caps to be slightly recessed into the material, you need to drill holes in the upper part using a drill of a suitable diameter.

- The hardware is best disguised using a color-matched putty.

Having completed all the above steps, you can safely put the finished home-made bench in its permanent place on the site. By a similar principle, it will be possible to make a table for a gazebo in the country.

How to create a metal bench-bed (or a bench-couch), see the video below:

Useful Tips

Let's get acquainted with some useful tips for making an iron or any other bench.

- If you are making a combined bench, it is recommended to treat wooden parts with antiseptics before attaching them to the metal frame. It will be more convenient this way.

- If you decide to make a bench from a shaped pipe, it must be filled with sand before bending certain parts. You should not forget about this nuance.

- Think carefully about the exterior design of the metal bench. It should harmoniously fit into the atmosphere of your summer cottage, not get out of it.

- When cutting metal, you need to take into account the thickness of the abrasive wheel. A more accurate fit is done by means of a grinder with a sharpening wheel.

Beautiful examples

Let's look at a few examples of how metal benches decorate areas.

- On the adjoining territory, a metal bench, stylized in antique style, without the use of wood details, will look gorgeous. The seat and backrest of the structure can be decorated with metal rosebuds. Such a product will look especially impressive against the background of stone walls or a fence.

- A frame welded from metal under a wooden seat does not have to have perfectly straight and regular lines. The legs of the structure can be thin, with slight bends. The metal back can be completely decorated with floral or floral ornaments. To give the shop a more interesting look, the metal parts can be painted dark green.

- A vintage bench will look great in the garden, in which the metal base is made up of openwork sidewalls and the same back, painted in white. Against the background of graceful lines and carved patterns, a seat made of dark natural wood will stand out well.

The comment was sent successfully.