Description and manufacture of benches from logs

A bench made of a log is an easy way to make a comfortable place to relax. If the bench is longer than human height and wide enough, you can lie on it, perform exercises for the neck, arms, back, abs and legs.

Advantages and disadvantages

Pros of using log benches:

- cheapness and simplicity of execution;

- readily available raw materials (boards, logs);

- aesthetic appearance, combination with an unassuming landscape gardening interior;

- poor thermal conductivity - logs will not freeze in winter and do not overheat in summer;

- environmental friendliness, the owner's contribution to the preservation of nature, the environment;

- the original shape of the logs sets a real flight of imagination for the owner;

- long service life, minimal maintenance costs.

Disadvantages of wooden benches:

- gradual destruction of wood, loss of its appearance due to lack of care;

- the need for an annual impregnation with antifungal agents and waterproof varnish;

- the wooden structure made of logs does not always match the design of the house.

In the latter case, a log bench, made simply and quickly, needs to be brought to a level that hides its shortcomings.

Species overview

Benches are primarily of two types - with and without a back. The garden bench is divided into many varieties in terms of design style. The originality of the idea of the master designer will easily bring the planned product beyond the capabilities of the existing subspecies. For example, a round log goes to the props, a sawn board goes to the crossbars and the flooring of a seat with a backrest. Let's try to combine individual varieties into groups.

- A regular bench without a back - an elongated seat made of a longitudinally sawn log. As props - stumps of trees that have outlived their own, pieces of large diameter logs (from tens of centimeters). If stumps or large logs are not available, industrial bricks, foam or cinder blocks are used, its length reaches tens of centimeters, and its width and height - up to 25 cm. Benches without a back and armrests lack the usual comfort. They are used only as a temporary seat on which you can relax after a dozen kilometers traveled or stubborn physical labor lasting several hours.

- Bench with backrest and armrests suitable for the most demanding users. The seat is made from planks obtained by multiple longitudinal sawing of logs. The backrest is similar: the owner will plan the consumption of the log, half of which will go to the seat, the second to the back. The leftovers after cutting the logs will serve as supports. Thinner and lighter parts of the log will fit up to the backrest. For unrivaled comfort, armrests also rely on the bench with a backrest. It is ideal when there is enough wood to complete a bench for a summer cottage or a country house completely.

- Stationary shops, which also include a table, cannot be folded in the fall and brought into the house or utility room. This option is located under the crown of a large tree in the garden. This bench is suitable not only for recreation, but also as a primitive workbench for work of serious complexity: this solution will be appreciated by owners of small houses who cannot afford a full-fledged office.

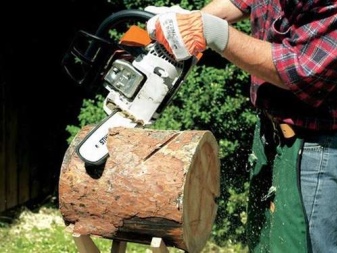

- There are types of benches made from solid logs. The master is required to be able to work with a chainsaw - a jigsaw or hand saws, it is extremely difficult to achieve accurate cutting in the shape of the future bench. For an even cut, a saw stroke is required according to a previously prepared drawing.

For a comfortable sitting on such a bench, you need a piece of a very thick log - up to 80 cm.

- Slightly different variation - circular bench - is made around the trunk of a living tree. With his own hand, the owner installs supports from logs, he makes seats and backs from sawn boards. The tree is stable enough to support the combined weight of several people with their backs to it. It is strictly forbidden to fix these components on a tree with the help of nails, self-tapping screws, through pins and bolts - the tree will quickly die off. If you still need to fix such a bench, tie its parts with ropes or ropes, but do not use fasteners that penetrate deep into the trunk.

Regardless of the design solution, the benches are divided into movable and non-movable. Overweight furniture built from old tree stumps cannot be carried. It is not a problem to move portable benches made of thinner logs to another place.

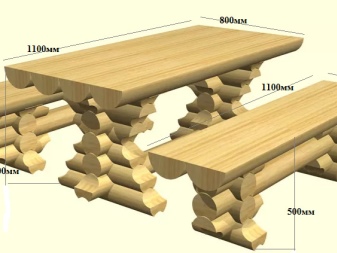

Drawings and dimensions

The sizes of garden furniture items are calculated individually by the owner of the cottage or house.

- The length of the bench is not limited - the longer it is, the more guests (visitors) can be seated. The typical length of a simple bench does not exceed 2.5 m.

- A variant is possible when several benches of a shorter length are located close to each other.

- For the convenience of vacationers, the width of the seat should be at least half a meter.

- The height of the back is about the same, but not lower than 40 cm.

- A back inclination of up to 10 degrees is required - a resting person has the opportunity to lean back on his back.

- The height of the legs is still the same half a meter. With an overestimated and underestimated position, the legs would get tired faster.

Tools and materials

The following tools work on wood:

- jigsaw;

- chainsaw;

- axe;

- grinder with cutting discs for wood;

- a drill with a set of drills for metal (the latter work ideally with wood as well).

As consumables, you will additionally need:

- emery wheels on the grinder,

- primer and paint (or waterproof varnish),

- any kind of wood (from soft to hard),

- impregnation from mold, fungus and microbes.

Measurements are taken using a tape measure and a building level. Marks and cut lines are drawn using a pencil or oil-based marker (non-drying felt-tip pen with a thick nib).

How to make do-it-yourself benches

The technological process is determined by the specific type of bench. The main stages are the same, but the existing differences make their own adjustments. Benches and tables that are notable for their beauty, for example, for a bath, are made of neat rounded or calibrated logs, which differ in approximately the same radius of the outer transverse bend. A solid log, for example, picked up in a forest windbreak, is dried in time for up to one year, peeled from the bark, leveled and polished from all sides, achieving a constant cross-section along its entire length. Garden and sauna benches are made of logs, beams and planks.

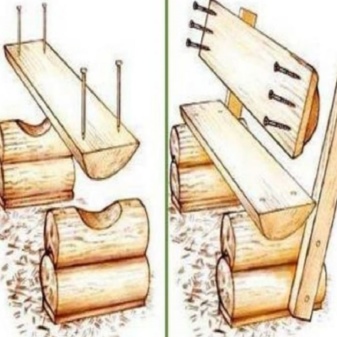

With back

It takes three long logs and two pieces to make a bench with a back. The latter should not be longer than 60 cm. The logs are cut and cut with a chainsaw and an ax. The algorithm of actions will help you to do all the work correctly.

- Divide a long and thick log in half lengthways - both halves will be used as the starting material for the seat and backrest.

- Bury two other smaller logs in the ground at a slight slope - they will serve as load-bearing supports for the back.

- For their stability close to the ground at the base, fix short pieces of log lying horizontally.Previously, they must be deepened with an ax - in place of the future back and seat.

- Clamp one of the halves of the sawn log onto the backrests. It will serve as a seat.

- Attach the second half of the same log in the same way - it will act as a backrest.

After assembling the bench, cover it with antifungal impregnation, primer and varnish.

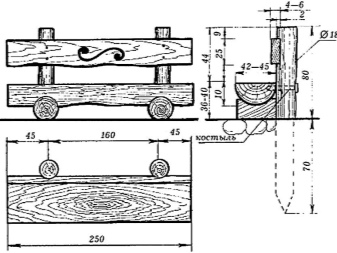

The carved bench differs from the usual one in more beautiful and even outlines. Only props are made with their own hands - individually they include two round pieces of logs, laid on top of each other. These props are connected with a thick bar - through artificially cut spikes and grooves. Backrest supports are also made of timber. As a seat - a wide board or a pair of narrow ones. After assembling the bench, patterns are cut out with a jigsaw. Carved decoration is also carried out on pre-prepared boards. Burning with an electric burner or a powerful laser pointer (or mini-gun) will complement this ornament.

To protect the eyes from the laser beam, protective goggles are used, resembling a welding helmet in shading.

Chopped

The chopped bench is made by the felling method. An ax and a chainsaw are actively used, as a consumable material - thick pieces of round logs of various lengths. You can get not one, but several benches. They are ideal for a combination of benches and tables. Follow the step by step instructions.

- Fold three logs in half lengthwise. The most accurate and even cut will be given by a sawmill.

- As the base of the bench, place two generalized supports, the role of which is played by thick sections of solid logs.

- Hollow out grooves under the seat (log halves) in the struts. Place the halves of the log on these indentations and fasten them together.

- For more than the seat, the rise of the future tabletop in the central part, put the trimmings on the props. The length of the round log segment and the width of the table top are equal. Use an ax to cut out the grooves on the scraps for round sections of the log.

- Place the remaining halves of the log.

- Align the boards of the tabletop with an electric planer - for a perfectly flat surface.

Cover the finished bench with varnish or paint.

From scraps of logs

For a bench made of scraps of a log, its segments no more than a meter long are suitable. The design feature is the similarity to a sofa.

- Use the four sections in the supine position for the two props. Place a piece of board on them, which later serves as a seat.

- For the backrest, use the pieces of log placed vertically and in a row.

- Use shortened logs for the armrests.

Protect the assembled structure from moisture.

From half-log

Half-log - a log cut in half lengthwise. Another option is a log in which the cut captures the entire core. The log is sawn at a right or obtuse angle - the core is excluded from it due to its looseness. The bark is removed, and only wood remains. The instruction will help you in your work.

- Cut the log in two. Assemble the bench according to one of the previous schemes, where halves of a log are used. The only difference is in the use of half-timbers and as props.

- When cutting a log at an angle - with a grip on the core - make an incision at intervals for the armrests.

Their number may be one more interval than people sitting on a long bench.

There is also a more complex instruction for making a bench from half-timbers.

- Saw one long log lengthwise - under the back and seat.

- Saw one of the short lengths (rounds) in half lengthwise.

- Place long pieces of log on it that match the length of the back and seat. Alternate them with short ones - just like laying out the corner of a log hut. The grooves of the short lengths of the log alternate with the untreated long ones.

- Install the main half-log on the last transverse (short) segments.The indentations must be strong enough so that the structure does not roll in different directions and injure anyone.

- If necessary, to secure the structure, use bolts with a diameter of M12-M20 with nuts and washers.

The design can be realized in the form of a non-fastening product - connections are made according to the “tongue and groove” method. The spikes and grooves should be strictly alternating, the more there are, the stronger the structure. For greater strength, use epoxy, carpentry or all-purpose glue.

A bench made of the remains of a log house is a product made of chopped logs, stacked one on top of the other near their ends. This is how huts were built earlier. The remains of the log house can be used to equip benches and tables that cannot be moved from place to place. Transfer from one place to another is possible only when the bench is completely disassembled. Assembly and disassembly are performed in the opposite order to each other. It is irrational to use fasteners here. A log house is also a half-log, sawn in two - the recesses for it in the underlying logs have a lower height.

From birch logs

Cuts of birch logs allow you to create an individual bench. It is independently assembled both according to one of the previous instructions and according to the scheme below.

- Saw a log with a diameter of 15-20 cm into pieces - 15-50 pieces in number. It is difficult to find a larger obsolete birch. With a smaller section diameter, the bench will not acquire the necessary stability.

- Bend the steel plate so that it follows the contours of the seat and back of the bench.

- Lay out the pieces of the log along the resulting metal frame.

- Mark in the plate and drill the holes for the self-tapping screws.

- Fasten each of the pieces of log to the plate using self-tapping screws.

The birch bark, preserved in good condition, serves as a decorative coating. It is impregnated with an antiseptic composition, then covered with a transparent waterproof varnish.

Soft woods make a street or country bench not as durable as harder counterparts.

By choosing a log of optimal quality, taking care of its protection, the owner of the object will turn a simple-looking bench into a work of art.

For information on how to make a simple bench from a log, see the next video.

The comment was sent successfully.