Varieties of split jet siphons and tips for choosing

The task of any plumbing is not only to eliminate leaks and unpleasant odors, but also to reduce the risk of dangerous microorganisms and other harmful substances entering the sink from the sewer system. This article discusses the main types of siphons with a jet gap, as well as advice from experienced craftsmen on their choice.

Design and principle of operation

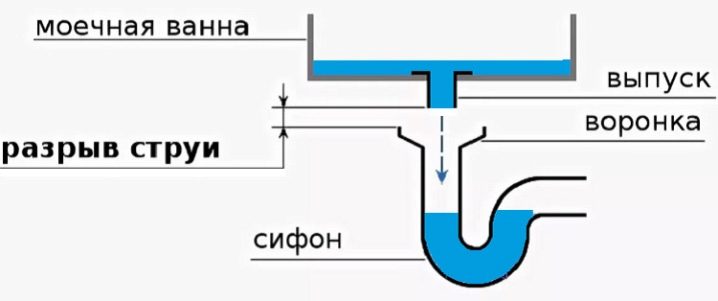

Unlike common siphon designs, which directly connect the drain of a sink or other equipment and the sewer system, options with a break in the water jet do not provide for such a direct connection. Structurally, such a siphon usually consists of:

- a drainage funnel, into which water is freely poured from the drain above it;

- an element providing a water seal;

- output leading to the sewer system.

The distance between the drain and the funnel in such products is usually between 200 and 300 mm.

With a lower rupture height, it is difficult to exclude contact between individual elements, and a high water drop height leads to an unpleasant murmur.

Due to the fact that the pipe connected to the sink in such a siphon does not have direct contact with the sewer pipe, the possibility of the penetration of dangerous bacteria from the sewer into the plumbing is almost completely eliminated. At the same time, the presence of an air gap in itself does not exclude unpleasant odors. That's why siphons with a break in the flow of water must be equipped with a water lock design.

Around the funnel in such devices, an opaque plastic screen is usually installed, designed to hide the freely falling unsightly drains from external users. Very rarely, and only in cases where the liquid discharged into the sewer does not contain impurities, the screen is not installed.

In such cases, the product can even serve as an element of room decor.

Application area

Legislatively adopted in Russia sanitary (SanPiN No. 2.4.1.2660 / 1014.9) and construction (SNiP No. 2.04.01 / 85) standards directly prescribe that in the kitchens of catering organizations (cafes, bars, restaurants), in canteens of schools and other educational institutions and at any other enterprises whose activities are related to the processing and preparation of food for citizens, it is imperative that siphons be installed with a break in the water flow, the height of which must be at least 200 mm.

Similar designs are used when connecting pools to the sewerage system. True, in this case, they are usually made in the form of overflow tanks with an installed burst valve.

In everyday life, systems without direct contact between the drain and the sewer are most often used for washing machines and dishwashers, where it is also important to exclude direct contact between the sewer and the insides of the device. But for washing in houses and even more so in bathrooms, such siphons are very rarely used.

Another common home use option for products with an air gap - drainage of condensate from air conditioners and drainage of liquid from the boiler safety valve.

Advantages and disadvantages

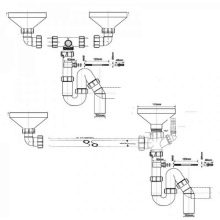

The main advantage of variants with an air gap over solid structures is the noticeably greater hygiene of such products. Another important plus is that it is much easier to organize the drainage of water from several sources into such siphons.This is due to the fact that the amount of drains is regulated by the width of the funnel, and the connection of additional consumers does not require additional inlets.

The main disadvantages of this design are more aesthetic than practical. Even with a relatively low height of free fall of water, it is capable of making unpleasant sounds.

In addition, errors in the design of such siphons are fraught with splashes and even the ingress of part of the wastewater outside.

Views

Structurally stand out several options for siphons with flow break:

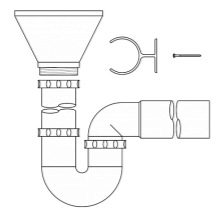

- bottle - the water castle in them is made in the form of a small bottle;

- U- and P-shaped - the water seal in such models is a knee-shaped bend of the pipe;

- P / S-shaped - a more complex version of the previous version, in which the pipe has two successive bends of different shapes;

- corrugated - in such products, the hose leading to the sewer is made of flexible plastic, which makes it possible to place corrugated models in a confined space.

Any siphon, if it is not a bottle siphon, has the name "two-turn", since the pipes have two or more turns. Also, all siphons, with the exception of the bottle variety, are sometimes called direct-flow, since the movement of water inside the pipes in such products is not interrupted.

According to the material of manufacture of the product there are:

- plastic;

- metal (usually brass, bronze, silumins and other aluminum alloys, stainless steel are used to create structures).

According to the design of the receiving funnel, products are usually divided into two main types:

- with an oval funnel;

- with a round funnel.

In terms of the diameter of the drainage pipe, models are most often found on the Russian market:

- with an output of 3.2 cm;

- for a pipe 4 cm;

- for an output with a diameter of 5 cm.

Models designed for connection with pipes of other diameters are very rare.

How to choose?

The most important element of any siphon is the hydraulic lock branch pipe. All other things being equal, it is always worth giving preference to models in which this element has a bottle design, since it is much easier to clean than models with a pipe bend. It is worth choosing corrugated options only in cases where all other structures cannot be fit into the available space. This is due to the fact that debris deposits are often formed on the corrugated walls, leading to the appearance of unpleasant odors, and it is much more difficult to clean such a siphon than products of other designs.

When choosing a material, it is worth evaluating the expected operating conditions of the siphon. If its location does not imply the risk of impacts and other mechanical influences, and the drained liquids will have a temperature of no more than 95 ° C, then the use of plastic products is quite justified. If boiling water is sometimes drained into the system, and the installation site of the siphon is not sufficiently protected from external influences, then it is better to purchase a product made of stainless steel or other metal.

When choosing the dimensions of the funnel, you should take into account the amount of drains that will be poured into it. The more pins are brought to this element, the wider its width should be. The funnel should be taken with a margin of width in order to exclude the formation of splashes, as well as to ensure the possibility of connecting additional drains in the future. Another nuance that is important to consider is that the material from which the element is made must be more resistant to high temperatures than the rest of the structure.

Before purchasing a specific model, it is important to first familiarize yourself with the reviews of people who have already purchased such a product. Particular attention should be paid to the reliability characteristics of the siphon.

For an experienced craftsman, it will not be difficult for an experienced craftsman to make a structure with a flow gap on his own using any conventional siphon and funnel of suitable dimensions.At the same time, it is important to use a sufficiently wide funnel, correctly adjust the elements to each other, ensure the tightness of the assembled system and adhere to the recommended height of the freely falling jet.

For an overview of the siphon with a jet gap, see the video below.

The comment was sent successfully.