All about channels

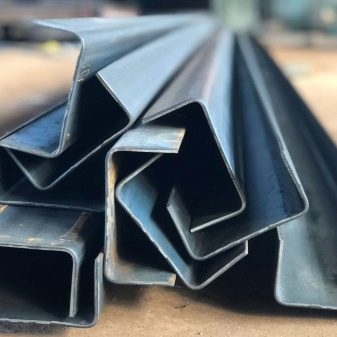

The channel has a U-shaped cross-section in the cross section. The main elements are the rear and the two side strips. In high-rise and low-rise construction, the construction of bridges and stairs, it is impossible to do without a channel.

What it is?

This structure, which is a cut-off "P" in cross-section, has significant resistance to bending compared to conventional strip or angle steel. The wall thickness is several millimeters - without this requirement, the channel is much easier to bend.

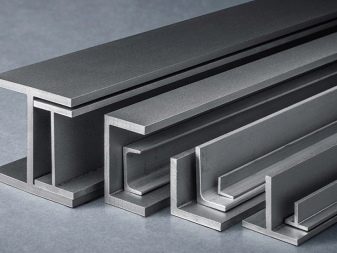

It can be placed in any of 4 positions: on the sidewalls, on the main wall and upward with the rear wall - the resistance to deflection will remain very high. The channel is produced in the form of products with equal and unequal (one cut off) shelves, with and without a shelf slope. The structure, which includes the channel and corners, looks quite stable.

Views

According to the material from which this element is made, they distinguish aluminum and steel pieces... Aluminum is easier to bend than steel, it has less strength, pure metal breaks easily and transfers vibration to further elements in the structure, almost without extinguishing it. Alloying aluminum with other metals - magnesium, copper, iron and other alloying additives - makes it possible to obtain a more plastic composition, however, the density and strength are not as high as in the case of steel.

Non-metallic channels - for example, made of plastic - are not available: the channel element must necessarily be metal, not composite or plastic. Many types of steels, with the exception of tool steels (of increased hardness), can be drilled and cut with relative ease in different projections.

Steel the same channels, although they are processed no less easily than aluminum (the same steel 3 is well drilled, welded, cut and turned), they have much higher hardness and strength. It follows from this that aluminum cannot be used as a starting material for the construction of load-bearing structures. However, for the construction of auxiliary frames, provided that its thickness in the element is three times the thickness of steel in a product equivalent in size, its use as a channel material is permissible.

For example, the covered bus stop is made using corners and channels, mainly of steel: The supporting structure must withstand hurricane and snowfall. But the framing of the plexiglass guides, thanks to which the transparent inserts of the sheet material will not fall out, can also be made from a bent aluminum channel with a thin U-shaped gap.

By design, channels are subdivided into bent (U-shaped in section) and sharp-angled (U-shaped). The former are used for finishing and supporting furniture frames, where sharp corners spoil the appearance of the product, the latter are used as supporting structures masked under cladding or plaster, whose task is to withstand the main weight effect, pressure from overlying elements and other attributes on a specific object, as well as from the people working on it.

By designation, the channel metal-roll is subdivided into automobile and carriage-building. The running, supporting structure of cars and wagons are taken into account, respectively, according to GOST 19425-1974 and 52671-1990. Such elements are produced in the form of segments 4-13 m.A special order for long-haul trucks - wagons for trailers, car tow trucks, cargo platforms for transporting military and special equipment, cars, aircraft parts and missiles - is made by prior agreement with the client. You cannot wind a channel in a bay; this would require a drum with at least a radius of several kilometers, it is produced only in the form of a segment. In practice, segments with a length from 2 to tens of meters are used.

Rolling mills produce channels of measured and unmeasured lengths. The measured length may be with a remainder of no more than 5% of the weight of the stack. The remainder of the length is added at least 3 mm. It makes no sense to use large "weights", since a large-sized channel for building structures is a massive and heavy product: the weight of a running meter can exceed 100 kg. By strength, the channel is classified into groups: A - high-strength, B - standard strength. Channel - first of all, a type of profile, which is subject to stringent strength requirements.

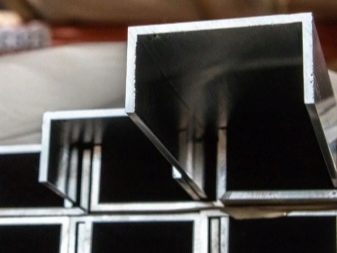

According to the design of the shelves, channels are produced with a slope of the shelves in the direction from each other. This means that not the shelves themselves are bent to the sides, but their thickness is variable - it decreases in the direction from the rear wall to the terminal side edges, which are parallel, like the shelf edges themselves, to each other. The angle of inclination of the inner sides of the side faces can reach three degrees to one of the longitudinal sides of the product.

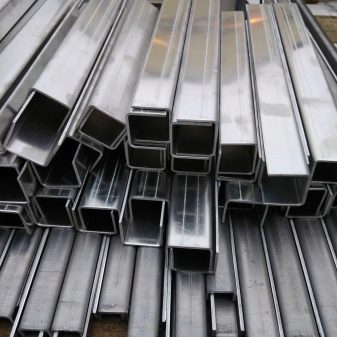

Equal and unequal channel elements are produced along the width of the shelves. Equality is rigidly specified by GOST 8278-1993. In terms of accuracy, the channels are subdivided into class A (high accuracy), B (increased) and C (standard). The channel cover can consist of different metals. Galvanized products are very popular. Anodizing the channel with copper, aluminum, chromium is much less common than galvanized units.

By the type of rolled products, hot-rolled and cold-rolled units are distinguished. Cold rolling implies smoother processing, eliminating roughness and other rough tolerances inherent in hot rolled products.

Specifications

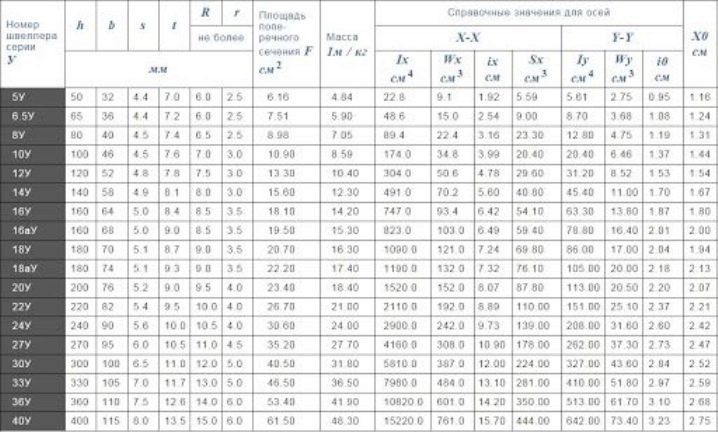

The height of the equal-flange channel is 50-400 mm, the width is 32-115 mm. In addition to measured and unmeasured lengths, these products are also produced as elements with a limited (within the limits of errors) length. These characteristics are strictly regulated by the same GOST 8281-1980. The calculation for the deflection is made by the method of comparison with the I-beam: according to the resistance to bending forces directed perpendicularly, the channel is inferior to the I-beam ("cross" in the cross section).

When designing structural supporting structures, the slope of the inner faces, the thickness of the rear (main) and side walls, the radius of rounding at the convergence of the main plank and sidewalls are taken into account. An equally important role is also played by the width of the wall and shelves, the weight of the entire segment and running meter, the grade of steel from which the product is made. Despite the fact that the channel can be made of St3 steel, other highly specialized grades can also be used, for example, the frost-resistant composition 09G2S. When corrosion resistance is important, medium- and low-carbon alloys with a high content of chromium and nickel are used, for example, alloys with a marker "X2", "X3", "X2H" in the designation and others. In rare cases, stainless steel channels are used, made of steels of the "X13" type and higher (from 13% chromium by weight composition).

For the manufacture of some types of channel, the following GOST standards apply: 8240-1997 - for hot-rolled products, 19425-1974 - T-shaped element (T-bar), I-beam and special channel, 8278-1983 - bent products, 8281-1980, bent unequal flange elements, 5422-1973 - "tractor" products, 5267.0- 1990 - "carriage" assortment, 21026-1975 - bent-shelf for bogies. The slope of the side shelves, amounting to 4-10%, is regulated by GOST 8240-1997.

Like all steel products, channels are easily painted over the entire area. Stale products, which have managed to get covered with a thin layer of rust, are first primed with a special primer. Today, this task is solved by the rust-based enamel: it reacts with the surface layer of iron oxide, stopping the further destruction of elements.

Marking

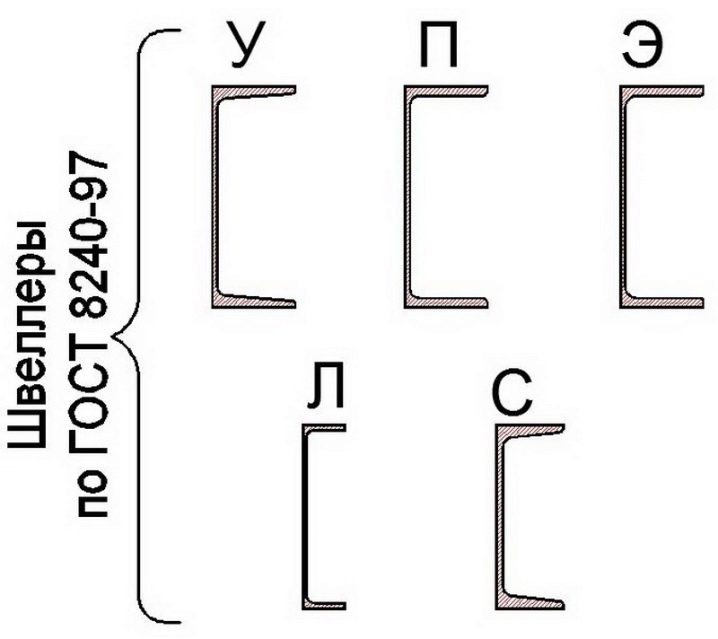

By design, channels are marked as "U" - with a slope of the inner sides of the sidewalls, "P" - strictly parallel with the standard version, "L" - lightweight with a parallel arrangement of edges, "C" - specialized, "E" - economical design. The penultimate of the above varieties are with technological gaps, perforation at a certain interval: both are used mainly in the machine tool industry.

Numeric marking provides an indication of the thickness of the back wall. Products called “channel-25” provide for a rear wall width of 25 cm. Dimensions 200x120 mm correspond to “20” nominal, which has an equal-shelf design, and the width of both sidewalls is 12 cm. If, for example, the attribute 200x110x120 is specified, then you have dealing with a product in which one sidewall has a width of 11 cm, the other - 12 cm, and the product itself is standardized as channel-20. The package or stack also indicates the GOST according to which the product was produced, and the grade of steel, for example, 09G2S, St4sp (“calm” steel 4) or, for example, 12X14H2 (one of dozens of stainless steel grades).

For the organization of interfloor floors, for example, product segments of 6 and 12 m are used. The length is mainly determined by the dimensions of the premises located between the load-bearing walls of the building.

Nuances of choice

The range of corners is much wider than the range of channel products. Use products of the appropriate type and class, choosing the brand that is closer to the smallest dimensions and weights. It is also necessary to take into account the moment of inertia along the axis, resistance along the axis of the element, and the radius of gyration. Novice developers simply take a product with a margin of safety (weight, thickness and width of the walls). The element must withstand three times the load that is supposed to be used for the construction of a structure or building: this is also important for maintaining the seismic resistance of the building.

You should also choose products that do not cause difficulties in processing. Two tasks are solved here: strength (elasticity, impact strength and hardness in an optimal combination) and extremely low hot brittleness and cold brittleness. Hot brittleness should be minimal - this means that the steel from which the channel is made has sufficient resistance to cracking during cooling immediately after weld seams are applied.

The integrity of the cooled weld is determined by the tendency of the steel alloy to thermal deformations, which prevent the formation of too many microcracks in the cooling weld. In this case, simple medium-carbon steels of the St3 type are not able to fully solve both of these problems. The distributor will select a channel for the customer with the necessary mechanical and physical characteristics that are appropriate in a specific situation, for example, during the construction of a frame-monolithic high-rise building.

Application

Along with corners, fittings and pipes, the channel sets the bearing strength, without which no building and no structure would have done. Thicker and larger elements are used for the construction of bridges and buildings, hangars, their smaller counterparts - for reconstruction, repair, redevelopment of already built objects. So, for repair and redevelopment work, the 20th channel is used - the height of its rear wall is 20 cm. The inclined side strips can withstand a greater load weight than straight ones.

Stainless steel channels can be used, for example, for the construction of historically significant structures and structures: stainless steel can stand in the rain for 100 years or more without loss of basic performance. In construction, channels are used not only for interfloor ceilings and wall frames, but also to strengthen window and door openings: in each of them, a segment of 1.5-2 m is sufficient.Risks of collapse of a part of the wall masonry above it are minimal: more than double safety factor, its deflection is excluded.

The machine-building industry provides for the use of channels made of steels other than St3 and similar compositions. For example, in the northern regions of Russia, the same frost-resistant alloy 09G2S, which has lower brittleness indicators, is used for carriage, machine-tool and machine-tool building. From this and similar alloys, the content of phosphorus and sulfur, affecting cold brittleness, is reduced to technologically minimal limits (0.005% for each of the impurities).

Machine-building and machine-tool steels used for the production of channel elements can be marked with the “A” symbol, which denotes a high degree of purification from harmful impurities. However, tool steels like U11, U12 are not used in the production of channel products: the task of the channel is to build a supporting frame and beams, and not cutting nozzles operating on a machine for a specific purpose. For example, a conveyor milling or automatic welding mill can have a channel-angle frame: this is done for stability, immobility of the supporting structure.

Small channels (10th, 12th denominations) are used to organize ramps. The latter make it easy for cyclists, scooters to move down from an elevation, and serve as guides for wheelchairs and carts for all kinds of purposes. Channel-20/25, reinforced with struts made of segments of the same rating, forms a ramp with a more powerful load pressure, suitable for garages, service stations, car service centers, where for a quick and successful repair it will be necessary to drive the car to a special elevation. The same devices are used on tow trucks: a channel ramp or platform is fixed on a powerful drive that raises and lowers this ramp.

For information on how to choose the right channel, see the next video.

The comment was sent successfully.