Everything you need to know about U-shaped channels

U-shaped channels are used in construction and other areas. Depending on the production method, the characteristics of the metal profile may be different, so the products must be selected for specific tasks. And also the builder should know how U-shaped channels differ from U-shaped channels similar to them.

Peculiarities

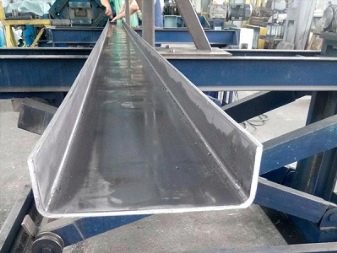

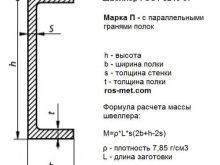

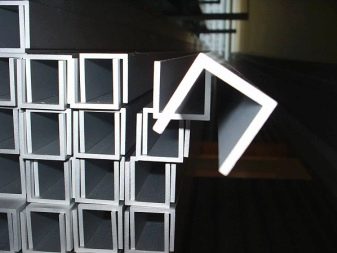

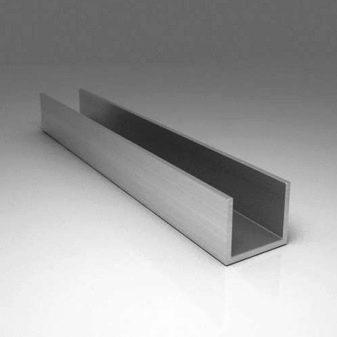

Products belong to the category of shaped metal products. They have a characteristic shape in the form of the letter "P", with parallel edges of the shelves. The material used is aluminum with magnesium alloys or other types of steels. The content of impurities may vary depending on the strength category of the profiles.

According to the production method, the U-shaped channel can be bent or hot rolled... The dimensions of the products are regulated by state standards, these parameters are reflected in the labeling.

In addition to numbers, the designation includes a letter indicating the type of product.

Comparison with U-shaped channels

Products with a slope of edges are outwardly similar to U-shaped rolled products, they also belong to the same category of profiles to which the general GOST applies, therefore the difference between them is insignificant, but there are some differences. First of all, you should pay attention to the form. The edges of the U-channels are located strictly parallel to each other, but the shelves of the U-channels can be sloped from 4% to 10% in accordance with the current standards.

Although the design difference is small, it does affect performance. The shape with a slope of the edges allows you to withstand more severe loads, such rolled products are stronger than U-shaped channels. However, due to their specific profile, Y-shaped products are not suitable for all tasks. Rolled metal with parallel shelves is considered universal. Both varieties have the same cross-sectional area and weight, so there is no difference in cost between them either.

If the technical task for the construction of a structure does not have strict load restrictions, then builders often choose U-shaped products as more practical.

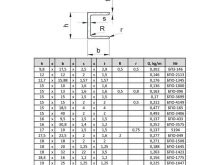

Specifications

The range of channels includes about 600 models with different sizes and weights. The standard length is from 6 to 12 meters. The shelf width can be in the range of 30-115 mm. The height reaches from 50 mm to 400 mm. The label usually contains all the necessary information. The dimensions are indicated there, for example, 100x50 or 80x40, as well as the wall thickness. Products with parameters from 3 mm to 10 mm are in demand, but in some cases profiles with indicators of 100 mm or more are required.

Despite the difference in dimensions and weight, this type of rental has common characteristics common to all models.

- Lightness combined with strength and rigidity. Low weight allows you to erect various structures without making the structure heavier. At the same time, the frames are capable of withstanding significant loads.

- Plastic... Products can be quickly given the required shape, depending on the task at hand, they are easily heat treated and machined. Welding can be used to connect parts.

- Corrosion resistant. The metal does not rust even in high humidity conditions. This makes the profiles suitable for use in various climatic zones, outdoors and indoors.

- Resistance to temperature extremes... Channel bars are designed for a wide range from –80 to + 100 ° С.

- Fire safety... The material does not burn and does not promote flame propagation.

Most of the channels are made from common and inexpensive metal, so the price of finished products is quite affordable. And also they can be recycled if necessary.

Views

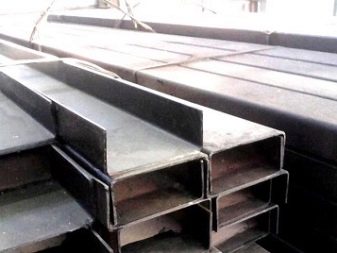

There are several classifications of channels. According to the manufacturing method, they are divided into hot-rolled and bent. These varieties have certain differences:

- hot rolled products have thickeningsdue to which the profile is more rigid and durable than bent;

- assortment of channels obtained by hot rolling, strictly limited by GOST;

- curved profiles weigh less, which allows faster to carry out installation work with them;

- complex equipment is required for the production of hot-rolled products, which only large companies and factories can afford.

The strength of the products depends on the composition of the steel used. The number of additives directly affects these indicators. Channel bars of normal and increased strength are distinguished.

Also, products obtained by hot rolling may differ depending on additional processing. Accordingly, the marking is assigned:

- T - hardened and naturally aged;

- T1 - artificially aged after additional hardening;

- T5 - aged, but not fully hardened;

- M - soft or annealed.

Products that have not undergone heat treatment do not have additional letters in the marking.

And you can also divide products into groups depending on the presence of a protective layer designed to enhance anti-corrosion properties. The coverage can be:

- paintwork;

- obtained by electrophoresis;

- from polymer powders;

- from two-layer compositions of a complex type;

- anodized - applied by electrolytic treatment.

There are general-purpose channels that are suitable for a wide range of jobs, as well as special ones - electrical products.

Materials (edit)

Steel is the main raw material for the production of such products... Specific grades and alloys are selected depending on the technical requirements. The most durable channels are stainless steel, varieties with molybdenum impurities are also appreciated - they provide resistance to aggressive environments. The cost of such rolled metal is quite high, therefore, if possible, it is replaced with a galvanized profile. In terms of corrosion resistance, it is not much inferior, but at the same time it is cheaper.

Aluminum channels are popular. These steel products are lighter, yet strong and can withstand a variety of loads. Less commonly, other non-ferrous metals are used in production. And also plastic models are available. PVC profiles are not as strong as metal ones, they are mainly used for finishing work.

Selection Tips

The main criterion when buying profiles will be the purpose, since each task has its own requirements. When choosing rolled metal products, it is important to know some indicators.

- What grade of steel was used as raw material. Hardness and strength, elasticity, and corrosion resistance depend on this.

- Processing method. Hot rolled and folded products will have different strength values.

- Geometric characteristics. Length, height, width of the shelf - to choose the right size channels for a specific project.

In addition, the profiles are selected according to the load, calculating the moment of resistance, the maximum allowable deflection, and stiffness. This is especially important when choosing elements that will become part of the supporting structure or frame.

Application

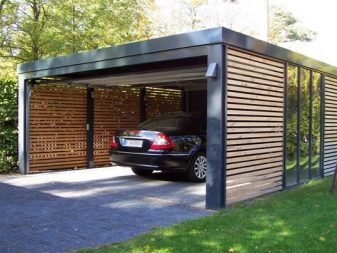

Channel bars are widely used in construction for the construction of large factory complexes, residential buildings, small objects - garages and pavilions. They are used for glazing facades, installing door and window openings. With the help of profiles, frames for billboards are formed. Metal products are suitable for the construction of fences.

Rental is also in demand in the shipbuilding, automotive and carriage industries. Similar elements can be found in any high-tech production. They are also used in the furniture industry, in the assembly of household appliances and for household needs in the private sector.

The comment was sent successfully.