All about bent channels

Unlike a conventional channel, whose design implies hot rolling from hot, slightly softened steel strips, a bent channel is made exclusively from the same strips, but using a roll forming conveyor.

Features of production

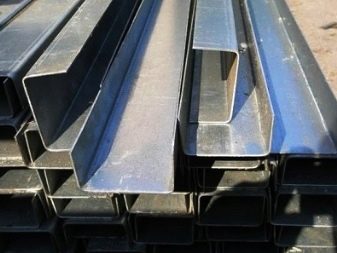

Steel bent channel - a profile from a pre-rolled elongated billet. Roll-formed channel steel belongs to the traditional types of rolled raw materials. The difference between classic hot rolled and cold formed channel - only in the most rounded, sharp corner on each side, which are the so-called shelves - side walls... In general, the U-shaped channel, sharp from the corners, is somewhat close to the rounded U-shaped element. The disadvantage of a bent channel is a noticeably lower margin of safety than a conventional one.

It is not recommended to use a bent channel in places where a high load is expected, for example, from brick or foam block masonry above the opening... The second reason for this decision is that the bent support has a lower contact area with the underlying row of brick (or foam block) masonry, and cement plastering will not eliminate this drawback.

In any case, the calculated load from the upper rows of the wall masonry on the lintel from such a channel will significantly exceed the recommended one, and the opening itself (and with it the wall) may collapse.

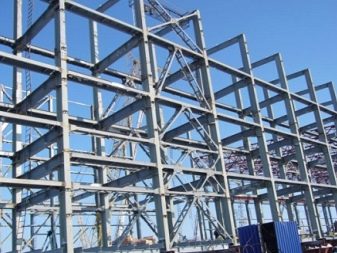

Channel bars are made mainly of steels with the usual composition - medium-carbon types St3Sp, St4, St5, St6. The bent channel is manufactured in such a way that its dimensional accuracy is high, and the above steel grades are easily welded. For example, welding of channel and other structures is in demand in the construction of shopping and entertainment centers, in which the main supporting structure is a steel monolith of prefabricated-welded type, and the walls, ceilings and roofs are covered with profiled steel, layers of hydro-vapor insulation, mineral wool as insulation, reinforcing frames for drywall, including the last one.

For each of the channel types, a your own GOST, deviations from which are already considered TU and serve as a reason for the sale of similar products already at reduced prices. The production process, as previously mentioned, consists in bending the strips on a profile-bending conveyor mill, which means that hot-rolled and cold-rolled steel in coils are the starting material for bent U-sections. In hot-rolled production, the internal structure (phase state) changes. Cold rolling makes it possible to create billets that are resistant to deformation phenomena. This technology provides for work at reduced temperatures, which means that the phase state of the steel alloy will not change, the original characteristics will not be violated.

The flat sheet, due to the action of the paired rolling shafts, turns into a bent profile fragment. This manufacturing method has a number of advantages in comparison with products of completely different samples, due to which the conveyor production process does not include the stages of finishing and auxiliary assembly actions. Steel used for the manufacture of roll-formed channels is hot-rolled and cold-rolled, structural, low- and medium-carbon steel. The result is products that are easy to install and maintain at the exit of the conveyor, meeting basic technical and aesthetic requirements.The standards of GOST and SNiP are not violated here.

Main characteristics

According to the parameters, channels, including bent products, are distinguished into a separate classification according to the following main features.

- Construction material - ordinary rusting steel or steel alloy with some resistance to rust formation. Cheap products are produced, as previously noted, from steels that are almost free of chromium and other improving (alloying) additives.

- Low alloy channel must be coated with a primer and paint (varnish) compounds resistant to moisture, despite the fact that the surface of the channel will be surrounded by masonry and plaster on all sides. However, the plaster absorbs water - the rusting channel must be protected. Chromium (including stainless steel) steel for a bent channel is a rarity, but it is also used, for example, in the manufacture of exclusive furniture (small channel material).

- Carbon content of raw materials - usually any steel with a mass fraction of carbon of at least 2 ppm is taken.

These two parameters put forward the basic requirements for a bent channel.

- Roll-formed channel bars should withstand significant loads along its axis.

- These products are fixed not only by welding, but also by bolts, which makes the assembly of the same furniture and auxiliary building structures easier.

- Assembled assemblies withstand significant loads on bending crush.

- Curved channel weight slightly less weight of a cut similar in length and dimensions classic "sharp-rolled" element.

- Curved products allow you to create something pretentious - non-standard construction.

- Pre-preparation - chamfering from such products is optional.

The listed features are the essence of the use of bent channel products.

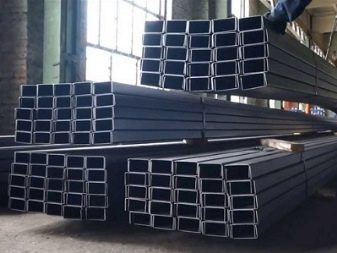

Assortment

Despite the inherent features of a bent channel, it has less weight and cost than a conventional one.

By rolling accuracy

The range of bent channels is represented by the following products: high, ultra-high and conventional accuracy... High and special precision is required for objects where maximum strength and stability are essential. Category "A" implies a mark of high accuracy, "B" - with the usual rate. Similar markings are found on special-purpose products.

By form

According to GOST 8278-1983, an equal shelf is produced, and on the basis of GOST 8281-1980, an uneven shelf... Steel strips are used for the blanks, the width of which is equivalent to the sum of the widths of the main and side strips. Channel products made of conventional steel alloys have a profile height from 2.5 to 41 cm, the width of the side bar ranges from 2 to 16 cm. The bent profile differs from the hot-rolled one both in appearance in cross-section and in terms of operating parameters.

Smoothed outer corners are characteristic of the bent profile fragment. Unequal samples are somewhat more difficult to manufacture: for their manufacture, not a standard rolling mill, but a pipe mill is used. The universal shape of the products is given with the help of universal machines capable of producing bent and unbent equi- and unequal items.

Dimensions (edit)

Typical dimensions of channels are 100x50x3, 100x50x4 120x50x3, 160x80x5, 300x80x6, 80x40x3, 120x60x4, 160x80x4, 400x90x4, 400x115x10, 160x60x4, 50x40x3, 200x80x6 and more than a dozen others. The height of the shelves is usually 80, 100, 60, 50 mm. The height of the main wall is 120, 160, 200, 140, 180, 250 mm. The wall thickness is also chosen differently - and is equal to 10, 12. 14 or 16 mm, but this is not a complete list of values. A thin-walled channel is not suitable for use as load-bearing support elements.

|

Central wall width, cm |

Side wall width, cm |

All wall thickness, mm |

Running meter weight, kg |

|

2,5 |

2,6 |

2 |

1,09 |

|

3 |

1,22 |

||

|

2,8 |

2,7 |

2,5 |

1,42 |

|

3 |

2,5 |

3 |

1,61 |

|

3 |

2 |

1,3 |

|

|

3,2 |

2 |

1,03 |

|

|

2,5 |

1,17 |

||

|

3,2 |

1,39 |

||

|

3,8 |

9,5 |

2,5 |

4,3 |

|

4 |

2 |

2 |

1,14 |

|

3 |

1,61 |

||

|

3 |

2 |

1,45 |

|

|

4 |

3 |

2,55 |

|

|

4,3 |

2 |

1,97 |

|

|

4,5 |

2,5 |

3 |

1,96 |

|

5 |

3 |

2 |

1,61 |

|

4 |

1,95 |

||

|

5 |

2,5 |

2,77 |

|

|

6 |

3 |

3 |

2,55 |

|

4 |

3,04 |

||

|

5 |

3,5 |

||

|

8 |

4 |

3,51 |

|

|

6 |

4,46 |

||

|

8 |

5,4 |

||

|

10 |

6 |

12,14 |

|

|

10 |

5 |

3 |

4,47 |

|

6 |

4,93 |

||

|

8 |

5,87 |

Focusing on specific needs, the consumer has the right to choose the size of the bent channel that meets his needs.For ultra-high workloads, they still use not a bent, but a conventional type of product.

Marking

In accordance with a specific method of manufacturing channel products, high- and low-temperature products are distinguished. The classification is complicated due to the presence of equal-, different-shelf and special and general-purpose samples. But the side strips are not always strictly perpendicular to the main wall of the product - in some samples, these sidewalls are slightly facing each other by bending, deviating inward. The average height of the main wall is 5 ... 40 cm, the height of the shelf strips (sidewalls) is 3.2 ... 11.5 cm.

In addition to the accuracy class, these products indicate notes on the values of the height of the main bar (H), the height of the sidewall (B), the depth of the product (S), and the bend radius (R). The production of an unequal channel is generally similar to the manufacture of an equal channel. The starting material for production is a roll-type cold-rolled billet with special strength. The numbering of the products coincides with the actual exact distance between the side strips of the product - it is indicated in millimeters. The dimension of different-shelf products coincides with the same dimensions of equal-shelf products.

In addition to the above marks, the designation of the variety of products is made by letter, namely:

- U - inclined shelves;

- P - side strips not bent towards each other;

- L - lightweight fragment;

- C - special profile.

In general, the metal consumption of bent products - in comparison with conventional ones - is reduced by a maximum of 30%.

Applications

Since channel billets are produced from steel St-3 or 09G2S, the sale of these products is possible both individually and in bulk.... Blanks are used to construct frames for architectural and industrial buildings. They are used as potential fittings for finishing structures and buildings from the inside and outside - although the fittings themselves are a completely different type of consumable building material. This product is used as the initial building material for the installation of overlapping decks, separating one room from another structure. For a protective function - fences, walls - the channel is also suitable. It welds well - the workpieces must be cleaned before weld seams are applied. However, for suburban summer cottage construction, the channel is rarely used: the main place in this direction is given to simple fittings, corners and T-elements.

Galvanized products are used, in addition to construction, for mechanical engineering and machine tool construction... It goes to the manufacture of cars and rolling stock. Galvanizing is not intended for use, for example, on roads that are sprinkled with salt or poured into ice and frost with salt-based de-icers: if used incorrectly, the product will quickly lose its zinc layer and begin to rust. Stainless steel channels would save a car or a car from rusting on channel parts, but on such a scale, this wheeled vehicle will pay off only in decades.

To protect the workpieces from rusting in a salty environment, several methods are combined: galvanizing, priming and painting with waterproof varnishes and paints.

The comment was sent successfully.