Types and rules for choosing screws

Many have had experience in fixing structures to concrete. One of the most common problems is drilling a hole in the desired location and then installing the fastening system. It is worth considering in more detail how to choose the right screws for concrete and what types of fasteners exist in principle.

What it is?

According to GOST 27017-86, a screw is interpreted as a special type of fastener, it has the shape of a rod. The screw construction also contains:

- thread of two types: external and special;

- a cone-shaped end;

- the head located at the top of the product.

In the process of use, the screws are screwed into holes pre-drilled with a screwdriver, using wooden or plastic bases for this. Mild steels are mainly used as the material for the manufacture of screws. Less commonly, steels with increased corrosion resistance are used.

It should be noted that no protective coatings are applied to the surface of such materials.

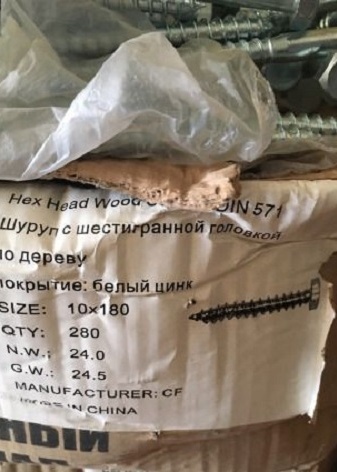

Several years ago, a new type of fasteners appeared on the domestic market, which are called structural screws. They have several features:

- modified structural elements (splines, ends and heads), the thread has also slightly changed;

- the use of steels and alloys with an additional protective coating.

Thanks to the release of new fasteners, manufacturers have been able to expand the functions of such products. They can now be screwed into concrete without the need to prepare holes for fasteners. This approach greatly simplifies the installation of the connected elements and their fixation with each other.

We also managed to expand the range of materials that screws can work with. Now, with such fasteners, you can connect elements made of wood, plastics. Added to the list bricks, alloys including copper and aluminum, composite materials.

The recently modified type of screws began to be called in a new way - self-tapping screws or structural screws. The structural elements of such fasteners include:

- head;

- slot;

- threaded rod;

- the end.

They significantly simplify work with any structure when it comes to organizing the attachment of additional elements to it.

Applications

Screws are used to work with different materials. Older versions of fasteners are used mainly for chipboard, using it as the main material. So, the screws are used during installation:

- forests;

- floor board;

- sandwich panels;

- wooden trusses;

- lathing.

Plumbing construction screws are also distinguished. Conventional self-tapping screws are enough to achieve the required strength and rigidity of the structure.

In addition, universal self-tapping screws can help solve various problems. Fasteners are often found in furniture factories, construction sites, during finishing work or other equally important tasks.

What are they?

There are several classifications of screw-screws. The most common division is by the type of cap, which can be:

- with a semicircular head;

- hidden;

- round;

- square or hex.

It is noteworthy that self-tapping screws also have such a classification, but their choice of options is wider. Therefore, there are more areas in which they are used.

Another way of dividing is to sort the screws according to the tip shape. They are:

- blunt - such products do not look very reliable, they are used to tie various elements;

- sharp crutch screws are considered the most popular.

The third classification implies the division according to the hook thread. In this case, the screws are grouped into the following types:

- single-pass;

- double-sided.

Additionally, it is worth noting the presence of L-shaped elements.

Often, the distribution of fasteners along the slots is performed. In this case, the screws are divided into the following types: cruciform, straight or hexagonal, track.

Additionally, decorative, plastic or brass screws are distinguished, depending on the material with which they have to work.

Dimensions and weight

The main parameters for small fasteners are size and weight. It is worth considering the first in more detail first. There are two main sizes of fasteners:

- diameter;

- length.

For the main diameter, take the one that allows you to determine the size of the circumference of the protrusions on the thread. Currently, more than 10 standard sizes of various screws are available with a diameter indicator from 1.6 to 12 mm.

A certain type of self-tapping screw does not always have all available diameters. The most popular in this regard are universal screws, the range of which is wider than the rest. For specialized self-tapping screws, the number of diameters is slightly less.

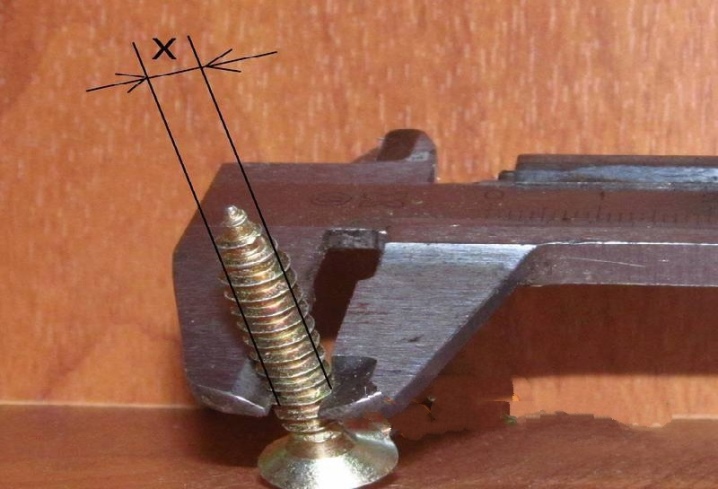

As for the length, this parameter is measured in two ways.

- For hidden head. The length is taken into account in full - from the bottom of the head to the end of the point of the product.

- For a convex head. The parameter is defined as the distance from the top of the head to the bottom of the self-tapping screw.

Regardless of the type of screw, the size range does not change in this case. It lies in the range from 4.5 to 300 mm. It is noteworthy that some specialized fasteners may have additional lengths based on individual customer requirements. It should be noted that a certain model of screws has a limited range of lengths.

Several parameters affect the choice of the diameter and length of the fastener:

- the load of the connection formed by the fasteners;

- dimensions of parts;

- the material into which you plan to screw the screw.

And this is not a complete list of factors that affect the final dimensions of the product. So, when determining the required diameter that you want to screw into a plastic expansion dowel, you should take into account the manufacturer's advice and recommendations. They are indicated on the package or in the passport.

The following statement is considered completely logical: the larger the diameter of the screw, the more durable the connection will be. However, at the same time, the amount of torque increases, and therefore there is a problem of head breakage or breakage of a tool that cannot cope with the drilling of material. The suitable screw length should be determined by summing the nominal length of the fastener dowel, the thickness of the element to be connected, and the diameter of the selected fastener. The last parameter will take into account the exit of the end of the self-tapping screw from the dowel.

Often companies involved in the production and sale of screws sell fasteners, calculating the price by weight. Therefore, this indicator is also considered important.

When calculating the weight of a fastener, it is recommended to take into account data from state standards and other regulatory documents. They contain tables showing the nominal weights of each screw.

Popular manufacturers

The production of screws is in demand where there is a demand for such fasteners. In other words, they are made in places close to large consumers who are ready to purchase a huge number of such products.

Most of the manufacturers are located in Russia, however, some types of self-tapping screws come to the country from abroad. At the same time, the countries of both near and far abroad are engaged in deliveries.

Here is a list of the most common screw manufacturers.

- "Roskrep". Domestic enterprise located in the Middle Moscow region. Carries out the manufacture of various types of high quality fasteners. Collaborates with various construction companies in Moscow and other cities of Russia.

- "Dneprometiz". A manufacturer from Ukraine, producing mainly universal types of self-tapping screws of various diameters and lengths.

- Stankoornal. Latvian screw manufacturing plant. Regularly supplies manufactured products to the territory of the Russian Federation.

- ARS-Prom. A sought-after company engaged in the production of fasteners and exhaust hoods. It also produces metal roofing tiles. The plant is located in Tyumen.

- Normand Fasternes. Despite the foreign name, the brand is considered domestic. The plant for the production of high-quality self-tapping screws is located in the Moscow region. Among other things, the manufacturer manufactures hardware and other types of fasteners.

- PROF-MET. The enterprise is located in the Ulyanovsk region. It is engaged in the production of various types of self-tapping screws that are in demand in many areas.

- "Integral". The company located in Nizhny Novgorod produces bolts, self-tapping screws, and air ducts. For the manufacture of elements, high quality steel is used, which is additionally coated with protective compounds.

The number of manufacturing plants is increasing every year. However, the list contains the most popular companies.

How to choose?

Before purchasing a screw, it is recommended to take into account several parameters:

- the estimated load that will be exerted on the product during operation;

- type of mounting block;

- the dimensions of the future screw, which you can calculate yourself;

- gaps between threads, determined by additional calculations.

On average, screws with sizes from 12 to 220 mm and a diameter of up to 6 mm are considered in demand. The rest of the fasteners should be classified in the specialized class. Medium pitch herringbone screws deserve special attention. In the case of their purchase, you will need to additionally purchase special dowels.

The comment was sent successfully.