All about furniture screws and screws

Furniture screws and self-tapping screws are used to assemble structures from chipboard, MDF and other wood-based materials. This fastener helps to facilitate and speed up the process of connecting various pieces of furniture.

Peculiarities

Furniture screws and screws are the 2 most common types of fasteners. Outwardly, they are quite similar: the products are metal rods with an external thread and a hat. Unlike screws, self-tapping screws are made from solid steel that has undergone heat treatment, which gives them additional strength. In the production of screws, soft types of steel alloys are used.

Another difference between the furniture screw is a sharper and higher thread, ending almost near the head itself.

The advantages of using these hardware:

- getting a reliable and accurate connection;

- high accuracy when fitting structural elements;

- cheapness and prevalence (fasteners are sold in almost any hardware or hardware store);

- the ability to withstand large power loads for fracture;

- ensuring a tight screed of parts;

- a large selection of products of different types and sizes.

Self-tapping screws are more convenient to use, since pre-drilling of holes is not required when fastening parts. Thanks to the tip in the form of a drill, they smoothly enter the material and are securely fixed in it. The disadvantages of self-tapping screws are possible distortions of the structure in case of careless work and loss of fastening strength during repeated screwing. The disadvantages of using screws is the obligatory punching of holes with a drill.

Areas of use

The main function of furniture screws and self-tapping screws is to connect various parts made of wood materials by screwing in and forming threads inside structural elements. They are used for attaching hinges, fixing handles.

They are used for the assembly of home and office furniture, as well as for builders and joiners to connect various structures.

With their help, cabinet furniture is produced from:

- solid wood canvases;

- MDF and chipboard;

- Chipboard;

- plywood;

- thin drywall.

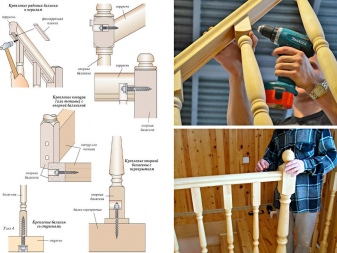

Hardware is used in the installation of wooden stairs, door frames, in the manufacture of structures with movable joints.

Species overview

Several types of self-tapping screws are used for wood. These include universal hardware with rare threads and a sharp end, and confirmations - products with a thickening in the upper part. The first ones have a flat head, which, when screwed in, is almost completely recessed into the material. Thanks to the carving, the hardware quickly enters the wood.

For the assembly of furniture, universal screws and confirmations (euro screws) are also used. In this case, the hardware head can have various features and shape. Products can be of several options.

- Countersunk head. When screwed into the material, the upper part of the hardware sinks, so that it does not protrude on the surface of the parts being fastened. It is recommended to use hardware with a countersunk head when installing shelves, hinges, handles.

- With a half-countersunk head. These products have a smooth transition from base to thread.

- With a semicircular hat. Due to this design feature, additional pressure is created on the connected parts. The assembled structure is more robust.

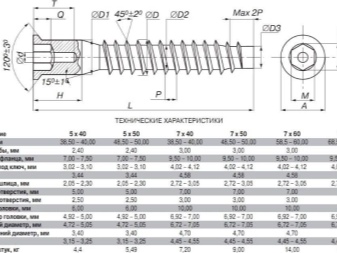

Another type of furniture screws is confirms. They have:

- coarse threaded pitch;

- blunt tip;

- a hat in the form of a cylinder;

- hex slot.

To make the furniture look attractive, you can choose decorative plastic plugs for screws, confirmations and self-tapping screws.

They are designed to mask the visible part of the head to match the furniture.

Materials (edit)

Screws and self-tapping screws are made from various types of steel. Wherein to increase the protective properties of hardware, their surface is coated with special compounds. It is the type of such a "shell" that you should pay attention to when choosing products.

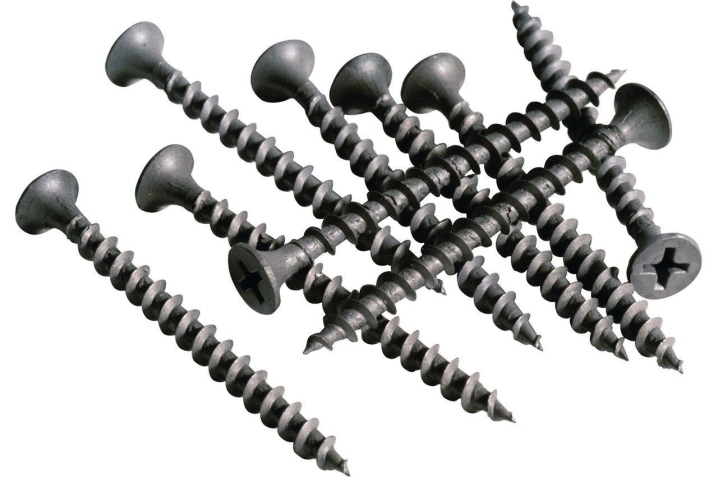

Matt black fasteners treated with phosphate-based agent. Phosphated products have poor corrosion resistance, which is why they are not recommended for the assembly of furniture used in rooms with high humidity.

Hardware with a black shiny surface is covered with an oxide film. It reliably protects the product from high humidity and water.

There are also chrome-plated fasteners on sale. It has a silvery color. When processing with chromic acid, a film is formed on the surface of the product, which protects the screw from various mechanical influences and corrosion. Chrome hardware is classified as decorative. They can be used in conspicuous places without the need for plugs or special stickers.

Hardware can also be galvanized and yellow passaged. They have a glossy white or gold finish to enhance the aesthetic qualities of the products. They are also referred to as decorative fasteners.

Nuances of choice

Before purchasing fasteners, you should know by what criteria they should be chosen, and what to look for.

- Dimensions of hardware (length, diameter and width of the cap). The most popular sizes of fasteners for furniture assembly are 3x16 mm, 3.5x16 mm, 4x16 mm. To find out the dimensions of the products, you need to look at the markings. For example, the designation 3.5x45 mm PH2 will tell you that this hardware has a diameter of 3.5 mm, a length of 45 mm and a cross-shaped slot. The sizes of one batch must be the same.

- Color spectrum. Hardware from the same batch must have the same shade. A uniform color will indicate that all products have undergone the same processing under the same process conditions. Their technical characteristics will be exactly the same.

- Slot holes must be deep, straight and clear - it will be convenient to work with such hardware, since they will not "slip" off a screwdriver or power tool.

- Fasteners must have the same thread pitch - this will ensure an even distribution of the load between the threads.

Before buying, you need to assess the quality of the hardware visually.

If you plan to purchase self-tapping screws with a tip, then their ends should be sharp, without burrs.

Breaks will indicate poor quality of the product.

Fastener rules

Most often, preparation is not needed to connect wood-based parts using self-tapping screws - the screws can be screwed into the part without drilling a hole. For these purposes, use a Phillips screwdriver or screwdriver. You need to act smoothly and carefully, especially when working with oxidized self-tapping screws (they are considered the most brittle).

The tool should be kept strictly in line with the screwed hardware. You should not try to screw the fastener into the knot - despite the fact that these are the tightest areas, such fastening will be considered ineffective. If self-tapping screws are planned to be screwed into high-density natural wood, it is recommended to pre-lubricate the hardware with laundry soap. It will act as a lubricant and provide an easier entry of the fastener into the material.

The connection of wooden elements with screws is slightly different. When choosing a hardware, you should give preference to a product that will be approximately 3 times the thickness of the part to be joined.

It should be borne in mind that the screw should not go through the 2 structures to be connected.

Before drilling, you need to apply a markup, and then make a hole in the main part 0.8 times the diameter of the screw. In depth, the hole should correspond to the screwed-in base of the hardware. If the fasteners are thin, you can use an awl.

When drilling soft sawn timber, manually punching holes is also allowed. For hard materials, drill a hole to match the profile of the screw-in fastener. To make a groove, you need a drill and a drill. It is best to use a countersink.

After preparatory work, the screw is inserted into the hole. It must be strengthened in the material by screwing it clockwise with a screwdriver. In this matter, the correct selection of hand tools is important. If you take a screwdriver of the wrong size, there are great risks of damage to the slot on the head - in this case, it will be impossible to tighten the fasteners. Screws can also be fastened using electric or pneumatic screwdrivers. Their use makes the work easier and speeds up the assembly process.

The final stage is the installation of stickers or plugs on the fastener heads. These accessories are sold in a wide range of colors. Their main task is to mask the fasteners. Thanks to the use of stickers, the aesthetics of the finished furniture can be increased.

For screws and self-tapping screws, see below.

The comment was sent successfully.