All About Ring Screws

On the hardware market, you can find a wide range of products. Not the last place in popularity is occupied by a ring screw used in domestic needs, as well as in some industries.

Peculiarities

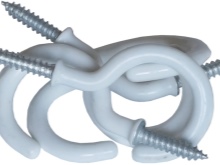

A ring screw is called a hardware, which is used for suspended structures or with large volumes. The self-tapping hook makes the installation process of the above items easier and faster. This element is called a screw ring, since it has a special design.

- A head that looks like a ring or half ring. In this case, the hook at the end continues the structure, and is not located as a separate element.

- Screw thread. With the help of this part of the hardware, immersion in the object is carried out.

The self-tapping hook is characterized by horizontal position in the working position. Its installation is usually carried out into walls or other vertical surfaces. This type of installation contributes to a certain loading of the screw to the maximum possible rate. The screw ring holds objects according to a simple principle: the thread expands in the material, and the screwed part in the hole made. In this case, the hardware is leveled and stretched.

The ring screw is made from a hardened type of carbon steel. From above, the surface of the product is coated with zinc, which protects it from corrosion. Bending of the screw occurs from steel wire, while the shape of the half-ring is observed.

The self-tapping hook has found its application with lightweight rigging items. With the help of this self-tapping screw, cables are laid and lights are attached. In construction, with its help, the forest is fixed to the facade of the building. It is not recommended to fix large objects with the ring downwards, as due to the high load on the thread, the product may fall. The manufacture of screws is strictly regulated by GOSTs, in particular GOST 1145-80, 1144-80.

The use of hardware can be directed to various needs. The ring screw is used both inside and outside buildings. Regardless of the operating conditions, external factors such as moisture can affect the device. Due to atmospheric precipitation, hardware often rusts, so the manufacturer often covers them with a special protective layer.

In addition, it is worth noting that the device with a stainless surface does not deteriorate after dismantling. This is especially true in those industries in which fasteners are the basis for the safe use of a structure.

Types and sizes

Varieties of looped hardware are associated with the peculiarities of closing their main part.

- With an unfinished ring.

- With a welded ring. Contributes to the reliability of fixing the suspended material. Such a ring does not unbend during use, so it can withstand significant loads.

The coating of hardware with a screw thread can also be different, in accordance with this characteristic, the products are divided into white and yellow. You can also find blue, brown, purple, gray fixtures on sale.

Among the variety of hardware, you can find an eye bolt. It looks like a metal ring rigidly connected to a cylindrical rod base. At the end of the product there is a thread that allows you to attach all kinds of structures. The eye is commonly used for wire rope, chain, brace, shackle, and more.

Also very popular are L-shaped small rectangular hardware and a half-ring screw.These products have a difference, which is a special shape for hanging. The installation option for such devices is no different from a ring screw.

According to GOST, manufacturers produce ring screws with the following dimensions (in mm): 3x10, 4x40, 10x120, 8x80, 6x80, 8x100, 6x60, 12x350, 4x30. However, products with dimensions of 4x45, 4x40, 5x50, 5x75, 6x65, 8x90, 8x120, 8x160, 10x160, 10x220, 12x90, 12x120 millimeters are in greater demand. In addition, on sale you can find products with non-standard dimensions. Given the size, a thousand self-tapping hooks can have such a mass:

- 2.97 kilograms - 3.5x75 mm;

- 9 kilograms - 5x50 mm;

- 10 kilograms - 5x75 mm;

- 57 kilograms - 3.5x75 mm.

Criterias of choice

A ring screw is quite practical when you need to create a secure fastener with a soft surface such as plastic or wood. In order for the choice of this hardware for scaffolding and other purposes to be correct, it is recommended to take into account the type of material to be fastened, as well as the load of the structure. When choosing a dowel, do not ignore the screw-in depth, since its diameter should be equal to the screw section.

The type of object to be fixed, the structure of the load-bearing wall, as well as the presence or absence of plaster will also help to choose a screw. Ring hardware for scaffolding is characterized by welded ring to the rod. This feature contributes to the fact that the product does not bend and can withstand heavy loads.

Craftsmen working with increased loads should pay attention to the version of the screw, which has a persistent round plate under the ring. The cost of a given device is influenced by its diameter and length.

You should not buy a product that is too cheap if it is not manufactured in accordance with GOST, since a low cost may indicate low quality, which can cause a situation that is dangerous to human health.

Mounting

For the installation of ring screws, first of all, it is worthwhile to calculate their number, which directly depends on the amount of work, the quality characteristics of the materials to be fastened, and the size of the products. The calculation of the exact number of hardware can only be carried out individually.

Fastening a self-tapping hook to a surface can be done by hand or using tools. In this case, you can use a screwdriver or a metal rod. To fasten the screw on a wooden surface, you will need to drill a hole and then start screwing the hardware inside. If you need to insert the product into concrete or brick, you will initially need to insert a spacer plastic dowel into the hole.

The principle of fixing a screw with a ring is practically no different from the procedure with other self-tapping screws. The algorithm traces the need to perform the following actions:

- drilling a hole - brick, concrete or stone walls are often the working surface;

- cleaning the surface from existing debris and dust;

- installation of a plastic dowel;

- screwing in a screw.

To select the correct hole diameter, you can take into account the following recommendations:

- if the hardware will be fixed to a solid surface, then the characteristics of the hole must match the dowel dimensions;

- if the screw ring is attached to a soft plane, then the hole diameter must be approximately 50-70 percent of the product diameter.

Fastening the screw may fail and there are several reasons for this:

- heterogeneity of the structure of the material into which the hardware was mounted:

- the presence of voids in the plaster;

- close proximity of the drilled hole to the corner, wall, brick joint.

After dismantling and unscrewing the hardware from the hole, the latter must be closed with a specially designed plug.

A protective type plate is able to adhere to the edges of the hole as much as possible, thereby isolating it and the dowel from water and debris.

The next video tells about life hacks when attaching ring screws.

The comment was sent successfully.