Features, advantages and disadvantages of lithium batteries for screwdriver

If a hand-held power tool powered by a household power supply is tied to an outlet with a wire, limiting the movement of a person holding the device in his hands, then battery-operated counterparts of the units "on a leash" provide much more freedom of action in work. The presence of a battery is very important when it comes to using screwdrivers.

Depending on the type of battery used, they can be conditionally divided into two groups - with nickel and lithium batteries, and the features of the latter make this power tool the most interesting for the user.

Peculiarities

The design of a lithium rechargeable battery is not too different from the design of batteries based on other chemistry. But a fundamental feature is the use of anhydrous electrolyte, which prevents the release of free hydrogen during operation. This was a significant disadvantage of the batteries of the previous designs and led to a high probability of fire.

The anode is made of a cobalt oxide film deposited on an aluminum base-current collector. The cathode is the electrolyte itself, which contains lithium salts in liquid form. The electrolyte impregnates a porous mass of electrically conductive chemically neutral material. Loose graphite or coke is suitable for it.... Current collection is carried out from a copper plate applied to the back of the cathode.

For normal battery operation, the porous cathode must be pressed tightly enough to the anode.... Therefore, in the design of lithium batteries, there is always a spring that compresses the "sandwich" from the anode, cathode and negative current collector. The ingress of ambient air can upset the carefully balanced chemical balance. And the ingress of moisture and does threaten the danger of fire and even explosion. That's why the finished battery cell must be carefully sealed.

A flat battery is simpler in design. All other things being equal, a flat lithium battery will be lighter, much more compact, and provide significant current (that is, more power). But it is necessary to design a device with flat-shaped lithium batteries, which means that the battery will have a narrow, specialized application. Such batteries are more expensive than their counterparts.

To make the sales market wider, manufacturers produce battery cells with universal shapes and standard sizes.

Among lithium batteries, the 18650 version actually dominates today. Such batteries have a form similar to the cylindrical finger batteries familiar in everyday life. But the 18650 standard specifically provides for slightly larger dimensions... This avoids confusion and prevents such a power supply from being mistakenly replaced in place of a conventional saline battery. But this would be very dangerous, since the lithium battery has two and a half times the standard voltage (3.6 volts versus 1.5 volts for a salt battery).

For an electric screwdriver, lithium cells are sequentially collected into a battery. This increases the voltage applied to the motor, which provides the power and torque required by the tool.

The storage battery necessarily contains in its design temperature sensors and a specialized electronic device - a controller.

This circuit:

- monitors the uniformity of the charge of individual elements;

- controls the charge current;

- does not allow excessive discharge of elements;

- prevents overheating of the battery.

Batteries of this type are called ionic. There are also lithium-polymer cells, this is a modification of lithium-ion. Their design is fundamentally different only in the material and design of the electrolyte.

Advantages and disadvantages

- The main advantage of lithium batteries is their high electrical capacity. This allows you to create a lightweight and compact hand tool. On the other hand, if the user is ready to work with a heavier device, he will receive a very powerful battery that allows the screwdriver to work for a long time.

- Another advantage is the ability to fill lithium batteries with energy relatively quickly. A typical full charge time is approximately two hours, and some batteries can be charged in half an hour with a special charger! This advantage can be an exceptional reason for equipping a screwdriver with a lithium battery.

Lithium batteries also have some specific disadvantages.

- The most noticeable is the significant drop in practical capacity when operating in cold weather. At subzero temperatures, tools equipped with lithium batteries have to be warmed up from time to time, and the electrical capacity is fully restored.

- The second noticeable drawback is not too long service life. Despite the assurances of the manufacturers, the best samples, with the most careful operation, withstand no more than three to five years. Within a year after the purchase, a lithium battery of any common brand, with the most careful use, can lose up to a third of its capacity. After two years, hardly half of the original capacity will remain. The average period of normal operation is two to three years.

- And another notable drawback: the price of lithium batteries is much higher than the cost of nickel-cadmium batteries, which are still widely used in handheld power tools.

Difference from nickel cadmium batteries

Historically, the first truly mass-produced rechargeable batteries for handheld power tools were nickel-cadmium batteries. At a low price, they are quite capable of relatively large loads and have a satisfactory electrical capacity with reasonable dimensions and weight. Batteries of this type are still widespread today, especially in the inexpensive handheld appliance sector.

The main difference between lithium batteries and nickel-cadmium batteries is low weight with high electrical capacity and very good load capacity..

In addition, very an important difference between lithium batteries is a significantly shorter charging time... This battery can be charged in a couple of hours. But the full charge cycle of nickel-cadmium batteries takes at least twelve hours.

There is another peculiarity associated with this: while lithium batteries tolerate both storage and operation in an incompletely charged state quite calmly, nickel-cadmium have an extremely unpleasant "memory effect"... In practice, this means that in order to extend the service life and also to prevent rapid loss of capacity, Nickel-cadmium batteries should preferably be used before full discharge... After that, be sure to charge to full capacity, which takes a significant amount of time.

Lithium batteries do not have this disadvantage.

How to choose?

When it comes to choosing a battery for a screwdriver, the task comes down to the selection of the electrical device itself, complete with which there will be a battery of a specific model.

The rating of inexpensive cordless screwdrivers this season looks like this:

- Makita HP331DZ, 10.8 volts, 1.5 A * h, lithium;

- Bosch PSR 1080 LI, 10.8 volts, 1.5 A * h, lithium;

- Bort BAB-12-P, 12 volts, 1.3 A * h, nickel;

- "Interskol DA-12ER-01", 12 volts 1.3 A * h, nickel;

- Kolner KCD 12M, 12 volts, 1.3 A * h, nickel.

The best professional models are:

- Makita DHP481RTE, 18 volts, 5 A * h, lithium;

- Hitachi DS14DSAL, 14.4 volts, 1.5 A * h, lithium;

- Metabo BS 18 LTX Impuls 201, 18 volts, 4 A * h, lithium;

- Bosch GSR 18 V-EC 2016, 18 volts, 4 A * h, lithium;

- Dewalt DCD780M2, 18 volts 1.5 A * h, lithium.

The best cordless screwdrivers in terms of reliability:

- Bosch GSR 1440, 14.4 volts, 1.5 A * h, lithium;

- Hitachi DS18DFL, 18 volts, 1.5 A * h, lithium;

- Dewalt DCD790D2, 18 volts, 2 A * h, lithium.

You can see that the best screwdrivers in the semi-professional and professional segments have 18 volt rechargeable batteries.

This voltage is considered the industry professional standard for lithium batteries. Since a professional tool is designed for long-term active work, and also implies an additional level of comfort, a significant part of the produced 18-volt screwdriver batteries are fully compatible with each other, and sometimes even interchangeable between tools from different manufacturers.

Besides, 10.8 volt and 14.4 volt standards are widespread... The first option is found only among the most inexpensive models. The second is traditionally a "middle peasant" and can be found both among professional models of screwdrivers, and in models of the middle (intermediate) class.

But the designations of 220 volts in the characteristics of the best models cannot be seen, since this indicates that the screwdriver is connected with a wire to a household power outlet.

How to remake and assemble?

Often, the master already has an old cordless screwdriver that suits him completely. But the device is equipped with outdated nickel-cadmium batteries. Since the battery will still have to be changed, there is a desire to replace the old battery with something newer. This will not only provide more comfortable work, but also eliminate the need to look for batteries of an outdated model on the market.

The simplest thing that comes to mind is to assemble a power supply from an electronic transformer in an old battery case.... Now you can use the screwdriver by connecting it to the household power supply.

14.4 volt models can be connected to car batteries... Having assembled an extension adapter with terminals or a cigarette lighter plug from the body of an old battery, you get an indispensable device for garage or work "in the field".

Unfortunately, when converting an old battery pack into a wired adapter, the main advantage of the cordless screwdriver is lost - mobility.

If we are converting an old battery to lithium, we can take into account that 18650 lithium cells are extremely widespread in the market. Thus, we can make screwdriver batteries based on readily available parts. Moreover, the prevalence of the 18650 standard allows you to choose batteries from any manufacturer.

It will not be difficult to open the case of an old battery and remove the old filling from it. It is important not to forget to mark the contact on the case to which the "plus" of the old battery assembly was previously connected.

Depending on the voltage for which the old battery was designed, it is necessary to select the number of lithium cells connected in series. The standard voltage of a lithium cell is exactly three times that of a nickel cell (3.6 V instead of 1.2 V). Thus, each lithium replaces three nickels connected in series.

By providing for the design of the battery, in which three lithium cells are connected one after the other, it is possible to obtain a battery with a voltage of 10.8 volts. Among nickel batteries, these are found, but not often. When four lithium cells are connected to a garland, we already get 14.4 volts.This will replace the nickel battery with both 12 volts.and 14.4 volts are very common standards for nickel-cadmium and nickel-metal hydride batteries. It all depends on the specific model of the screwdriver.

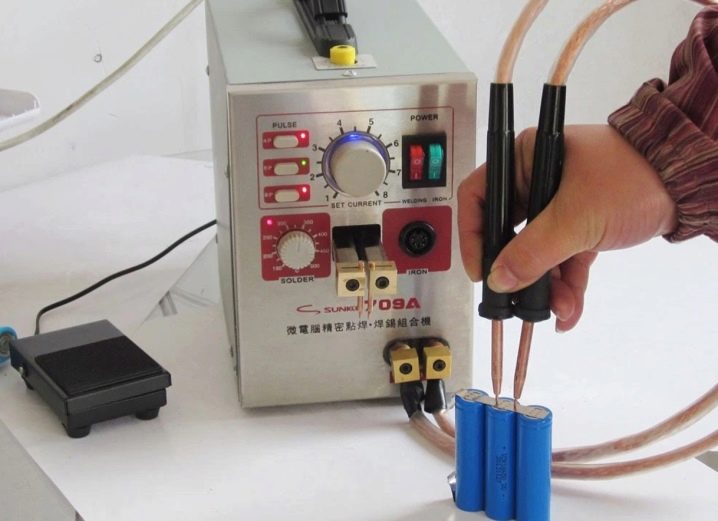

After it was possible to determine the number of successive stages, it will probably turn out that there is still free space in the old building. This will allow two cells to be connected in each stage in parallel, which will double the battery capacity. Nickel tape is used to connect lithium batteries to each other in production.... Sections of the tape are connected to each other and to lithium elements by resistance welding. But in everyday life, soldering is quite acceptable.

Soldering lithium cells should be done with great care. The joint must be thoroughly cleaned beforehand and a good flux must be applied. Tinning is done very quickly, with a well-heated soldering iron of sufficiently high power.

The soldering itself is done by quickly and confidently heating the place where the wire is connected to the lithium cell. To avoid dangerous overheating of the element, the soldering time should not exceed three to five seconds.

When designing a homemade lithium battery, you should take into account that it is charged in a special way. It is imperative to provide an electronic circuit for monitoring and balancing the charge in the design of the storage battery. In addition, such a circuit should prevent possible overheating of the battery and excessive discharge. Without such a device, a lithium battery is simply explosive.

It is good that now there are ready-made electronic control and balancing modules on sale at fairly low prices. It is enough to choose a solution that suits your particular case. Basically, such controllers differ in the number of series-connected "steps", the voltage between which is subject to equalization (balancing). In addition, they differ in their permissible load current and temperature control method.

Anyway, it is no longer possible to charge a homemade lithium battery with an old nickel battery charger... They have fundamentally different charging algorithms and control voltages. You will need a dedicated charger.

How to charge correctly?

Lithium batteries are quite picky about charger specifications. Such batteries can be charged fairly quickly with a significant current, but excessive charging current leads to severe heating and fire hazard.

To charge a lithium battery, it is imperative to use a special charger with electronic control of the charge current and temperature control.

It should also be borne in mind that when cells are connected in series in a battery, lithium sources are very prone to uneven charging of individual cells. This leads to the fact that it is not possible to charge the battery to its full capacity, and the element, which regularly works in undercharged mode, simply wears out faster. Therefore, chargers are usually built according to the "charge balancer" scheme.

Fortunately, all modern factory-made lithium batteries (except for outright fakes) have built-in protection and balancing circuits. However, the charger for these batteries must be specialized.

How to store?

What's great about lithium batteries is that they are not overly demanding on storage conditions. They can be stored, whether charged or discharged, at almost any reasonable temperature. If only it was not too cold. Temperatures below 25 degrees below zero are fatal for most types of lithium batteries. Well, and above 65 degrees of heat, it is also better not to overheat.

However, when storing lithium batteries, be sure to take into account the very high risk of fire.

With a combination of a low state of charge and a low temperature in the warehouse, internal processes in the battery can lead to the formation of so-called dendrites and cause spontaneous self-heating. This kind of phenomenon is also possible if highly discharged batteries are stored at high temperatures.

The correct storage conditions are when the battery is at least 50% charged and the room temperature is from 0 to +40 degrees. At the same time, it is advisable to save the batteries from moisture, including in the form of droplets (dew).

You will find out which battery is better for a screwdriver in the next video.

The comment was sent successfully.