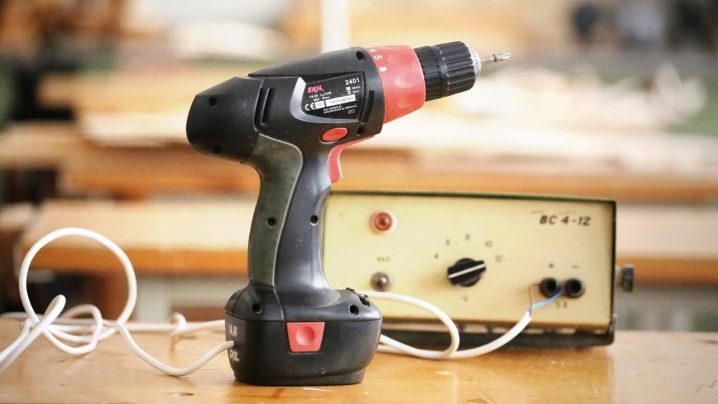

How to make a network out of a cordless screwdriver?

A cordless screwdriver is a necessary thing in the household, the main advantage of which is its mobility. However, during long-term operation, the tool requires regular recharging, which is very inconvenient. In addition, old batteries fail, and it is expensive or even impossible to purchase new ones, since the model may be discontinued. A rational solution is to build a constant power source for the screwdriver.

Advantages and disadvantages of rework

Before starting work, you should evaluate all the pros and cons of upgrading the tool from a battery to a network one. The main disadvantage is the loss of mobility, which is not always convenient for working at a height or far from the outlet. As for the advantages, there are several positive factors at once:

- the problem of suddenly discharged batteries disappears;

- stable torque;

- no dependence on temperature conditions (at low values the batteries are discharged faster);

- saving money on buying new batteries.

Modernization is especially relevant when the "native" batteries are out of order, and new ones are either not on sale, or you need to go far to get them. It also happens that the purchased device has some problems when receiving energy from the battery. This may be a marriage or flaws in the circuit of the model itself. If, in principle, the tool suits, then it is advisable to remake it and charge it from the mains.

Power supply options

Since the screwdriver requires a voltage much lower than in a centralized network, an electrical adapter is needed for a power tool - a power supply that will convert 220 Volts AC to 12, 16 or 18 Volts DC. There are several options for the power supply.

Pulse

Pulse devices - inverter system. Such power supplies first rectify the input voltage, then convert it into high-frequency pulses, which are fed either through a transformer or directly. Voltage stabilization through feedback is achieved in two ways:

- due to the output transformer winding in the presence of sources with galvanic isolation;

- using a conventional resistor.

Experienced craftsmen prefer a switching power supply, since it is small. Compactness is achieved due to the absence of a power transformer.

Such a power source, as a rule, has a fairly high efficiency - about 98%. Impulse units provide protection against short circuit, which ensures the safety of the device, as well as blocking in the absence of load. Among the obvious disadvantages, the main one is the lower power compared to the transformer version. In addition, the operation of the device is limited by the lower load limit, that is, if the power is below the permissible level, the power supply will not work. Users also report an increased level of repair complexity compared to a transformer.

Transformer

Transformers are considered the classic version of the power supply. A linear power supply is a symbiosis of several components.

- A step-down transformer. The winding of the power device is designed for the mains voltage.

- A rectifier, the function of which is to convert the alternating current of the network into direct current. There are two types of rectifiers: half-wave and full-wave. The first consists of 1 diode, in the second - a diode bridge of 4 elements.

Also, the circuit may include other components:

- a large capacitor, necessary to smooth out ripple, located after the diode bridge;

- a stabilizer that provides a constant output voltage, despite any surges in the external network;

- protective block against short circuits;

- high-pass filter to eliminate interference.

The popularity of transformers is due to their reliability, simplicity, possibility of repair, absence of interference and low cost. Among the disadvantages are only bulkiness, high weight and low efficiency. When choosing or self-assembling transformer power supplies, it should be borne in mind that the output voltage should be slightly higher than the tool required for operation. The fact is that part of it is taken by the stabilizer. For example, for a 12-volt screwdriver, a transformer power supply with an output voltage of 12-14 volts is chosen.

Specifications

When buying or self-assembling a power supply always start from the required technical parameters.

- Power. Measured in watts.

- Input voltage. In domestic networks 220 volts. In other countries of the world, this parameter is different, for example, in Japan 110 volts.

- Output voltage. A parameter required for the operation of a screwdriver. Typically ranges from 12 to 18 volts.

- Efficiency. Reflects the efficiency of the power supply. If it is small, it means that most of the converted energy goes to heating the body and parts of the tool.

Required materials and tools

In work on the modernization of a cordless screwdriver you can use the following set of tools:

- screwdrivers of various types;

- pliers;

- nippers;

- construction knife;

- insulation in the form of a tape;

- electric cable (preferably stranded), wire for jumpers;

- soldering station including soldering iron, solder and acid;

- a case box for a power supply, which can be an old battery, a factory-made device, a home-made box.

When choosing a box, you need to take into account the dimensions of the power supply design so that it fits inside the device.

How to do it yourself

In order for the screwdriver to work from a 220 Volt network, it is necessary to build a power supply that outputs 12, 14, 16 or 18 Volts, depending on the model of the tool. Using the existing battery charger housing, you can perform mains charging by following the steps below.

- Determine the dimensions of the case. The network block must be sized to fit inside.

- Small-sized sources are usually placed in the body of the screwdriver itself. To do this, you need to disassemble the battery and remove all the insides. Depending on the model of the tool, the body can be collapsible or glued. In the latter case, you will have to open the tool along the seam with a knife.

- Using the marking, we determine the voltage and current. As a rule, manufacturers do not indicate the last parameter, but instead there is such as power, or total electrical load, expressed in watts. In this case, the current will be equal to the quotient of dividing the power by the voltage.

- At the next stage, an electrical wire must be soldered to the contacts of the charger. Since the terminals are usually made of brass and the conductors are made of copper, this task is difficult to accomplish.For their connection, a special acid is used, which is used to treat the brass surface before soldering.

- The opposite ends of the wire are connected to the outlet of the battery. Polarity is important.

In order for the power supply to work correctly, you must connect the cable following all the rules:

- a hole is made in the structure to lead a wire there;

- the cable is fixed inside the housing with electrical tape.

Of course, it would be easier to connect to the network directly with a plug and socket. However, in this case, the device will refuse to work. Firstly, because it is designed for a constant low voltage, and in the network it is variable and large. Secondly, it's safer that way. Elements for the electrical circuit (diodes, resistors, etc.) are required, you can buy, or you can borrow from unnecessary household appliances, for example, from an energy-saving lamp. It happens that it is more advisable to make a power supply unit completely by hand, and sometimes it is better to buy a ready-made one.

Homemade block

The easiest way to assemble a charger is to use the case from your own battery, which has become unusable. In this case, either a Chinese 24-volt power supply unit, or some ready-made power supply units, or a power source of its own assembly will be useful for internal filling. The beginning of any modernization is an electrical circuit. It is not necessary to draw it according to all the rules, it is enough to draw by hand the sequence of connecting the parts. This will allow you to identify a number of elements necessary for the work, and will also help to avoid mistakes.

Alteration of a Chinese-made PSU

A similar source is designed for an output voltage of 24 volts. It can be easily bought at any retail outlets with radio components, it is affordable. Since most screwdrivers are designed for operating parameters from 12 to 18 volts, you will have to implement a circuit that lowers the output voltage. This is pretty easy to do.

- First of all, you should remove the resistor R10, which has a constant resistance of 2320 Ohm. He is responsible for the magnitude of the output voltage.

- An adjustable resistor with a maximum value of 10 kΩ should be soldered instead. Since the power supply has built-in protection against turning on, before installing the resistor, it is necessary to set a resistance equal to 2300 ohms on it. Otherwise, the device will not work.

- Next, electricity is supplied to the unit. The values of the output parameters are determined with a multimeter. Remember to set the Meter to DC voltage range before measuring.

- With the help of an adjustable resistance, the required voltage is achieved. By using a multimeter, you need to check that the current does not exceed 9 Amperes. Otherwise, the converted power supply will fail, as it will experience large overloads.

- The device is fixed inside the old battery, after removing all the insides from it.

Alteration of purchased blocks

Similar to the Chinese device, it can be built into the battery box and other ready-made power supplies. They can be purchased at any radio parts store. It is important that the selected model is designed to work with a 220 volt network and has a suitable operating voltage at the output. Modernization in this case will be carried out as follows.

- First, the purchased device is disassembled.

- Next, the structure is redesigned for the required parameters, similar to the reconstruction of the Chinese power source described above. Solder the resistance, add resistors or diodes.

- The length of the connecting wires should be selected based on the dimensions of the battery compartment of the power tool.

- Carefully insulate the soldered areas.

- It is better to equip the board with a heatsink for cooling.

- It is more expedient to place the transformer separately.

- The assembled circuit is mounted inside the battery compartment and fixed. For reliability, the board can be glued.

- Connect the electrical cable with regard to polarity. All conductive parts must be insulated to avoid short circuits.

- Several holes must be drilled in the housing. One is for the outlet of the electrical cable, the others are for the removal of hot air in order to ensure circulation and reduce the degree of heating of the screwdriver during operation.

- Upon completion of the work, the operation of the device is checked.

Self-designed power supplies

Parts for assembly are taken either from various household electrical appliances or energy-saving lamps, or purchased from amateur radio outlets. It is necessary to understand that the electrical circuit will also depend on the set of elements. To assemble it, you need certain radio engineering knowledge and skills. Graphic options for schemes can be found on the Internet or in specialized literature.

In the simplest case, you will need a ready-made 60-watt electronic transformer. Experts advise to choose devices from Taschibra or Feron. They do not need alteration. The second transformer is assembled by hand, for which a ferrite ring is purchased, the dimensions of which are 28x16x9 mm. Next, using a file, the corners are turned. Upon completion, it is wrapped with electrical tape. It is better to choose an aluminum plate with a thickness of 3 mm or more as a board. It will not only perform the supporting function of the base for the entire circuit, but also simultaneously conduct current between the elements of the circuit.

Professionals recommend including an LED light bulb in the design as an indicator. If its dimensions are sufficient, then it will also perform the task of highlighting. The assembled device is fixed in the screwdriver battery case. When designing, it must be remembered that the dimensions of a home-made power source should in no case exceed the dimensions of the battery pack.

PC connection

Remote power supplies can be designed based on a laptop or computer power supply.

From a computer PSU

As a rule, craftsmen use AT-type blocks. They have a power of about 350 watts and an output voltage of about 12 volts. These parameters are enough for the normal operation of the screwdriver. In addition, all the technical characteristics are indicated on the case, which greatly simplifies the work of adapting the power supply to the instrument. The device can either be borrowed from an old computer or bought from a computer store. The main advantage is the presence of a toggle switch, a cooling cooler and an overload protection system.

Further, the sequence of actions is as follows.

- Dismantling the case of the computer unit.

- Elimination of protection against inclusion, which consists in connecting the green and black wires that are present in the specified connector.

- Working with MOLEX connector. It has 4 wires, two of which are unnecessary. They must be cut off, leaving only yellow at 12 volts and black - ground.

- Soldering to the left wires of the electrical cable. Particular attention should be paid to insulation.

- Dismantling the screwdriver.

- Connect the tool terminals to the opposite end of the electrical cable.

- Assembling the tool. It is necessary to ensure that the cord inside the screwdriver body does not twist and is not tightly pressed.

As a disadvantage, one can single out the adaptability of such a power supply unit only for an instrument with an operating voltage not exceeding 14 Volts.

Laptop charger

The power source for the screwdriver can be a laptop charger. Its revision is minimized. It should be noted that any device for 12-19 volts is suitable for use. The algorithm of actions is as follows.

- Preparing the output cord from the charger. Using pliers, cut off the connector and strip the ends of the insulation.

- Disassembly of the tool body.

- The bare ends of the charger are soldered to the screwdriver terminals, observing the polarity. You can use special plastic ties, but professionals advise not to neglect soldering.

- Insulation of connections.

- Assembling the body of the power tool.

- Performance testing.

Alteration of a ready-made charger is easier and accessible to everyone.

Car battery

An excellent option for powering a screwdriver is a car battery. Especially in cases where repairs are required in an area without electricity. The negative point is that the tool can be powered from the car battery only for a short time, since the vehicle runs the risk of being discharged and will not move. To start a screwdriver, an old analog-type car battery is sometimes altered. This device is characterized by manual control of the amperage and output voltage.

Modernization instructions.

- The first step is to select a pair of multicore cables. It is desirable that they be wrapped in different colors to distinguish them, but of the same section.

- On the one hand, contacts in the form of "crocodiles" are attached to the wires, on the other, the insulating layer is stripped by 3 centimeters.

- Bare ends are crocheted.

- Next, they begin to disassemble the screwdriver body.

- Find the contact terminals with which the tool was connected to the battery. Bent stripped cable ends are soldered to them. You can do without soldering using special plastic ties, but professionals prefer a soldering iron.

- The connections must be well insulated, otherwise there is a risk of short circuits.

- Both ends of the cable are tucked neatly inside the housing and led out through the handle. You may need to drill additional holes for this.

- The next step is to assemble the tool.

- After all the manipulations, the device is tested. With the help of "crocodiles" the screwdriver is connected to the car charger, observing the "+" and "-".

Such an analog power supply is convenient in that it allows you to smoothly adjust the parameters, adjusting to any model of a screwdriver.

Inverter welding machine

The creation of a power source from inverter welding is a more complex type of modernization, since it implies the presence of certain theoretical knowledge in the field of electrical engineering and practical skills. Alteration entails structural changes to the equipment, which will require the ability to make calculations and draw up diagrams.

Precautionary measures

When working with any electrical appliance that has been retrofitted, certain safety rules must be followed.

- First of all, when reworking, in no case should you neglect good insulation of contacts and grounding.

- The screwdriver requires short breaks every 20 minutes. During the alteration, the technical characteristics changed, which were laid down by the manufacturer and were designed to operate on a battery. The increase in power resulted in an increase in the number of revolutions, which causes the tool to heat up. Small pauses will extend the operating life of the screwdriver.

- It is recommended to regularly clean the power supply from dust and dirt. The fact is that during the modernization, the tightness of the case was broken, so dirt and moisture gets inside, especially when working in the open air.

- Do not twist, pull or pinch the power cable. It is imperative to monitor so that during operation it is not exposed to any negative influences that can lead to a short circuit.

- Experts advise against using a homemade cordless screwdriver at a height of more than two meters. Since this automatically entails tension on the wire under its own weight.

- When adjusting the output parameters, you need to choose a current 1.6 times greater than the electric capacity of the battery.

- You should be aware that when a load is applied to the device, the voltage can drop from 1 to 2 volts. In most cases, this is not important.

These simple guidelines will extend the life of the screwdriver and keep the owner safe from trouble.

As practice shows, self-alteration of a power supply unit requires experience and good theoretical knowledge of electrical engineering. Therefore, before choosing, you need to decide whether you are ready to spend your free time on drawing up a circuit, assembling a power supply, especially if you do not have the proper skills. If you are not sure, then experts advise buying ready-made chargers, especially since their cost in the market is low.

For information on how to make a network out of a cordless screwdriver, see the next video.

The comment was sent successfully.