Screwdriver batteries: types, selection and storage

Battery-powered screwdrivers are a popular type of tool and are widely used in construction and everyday life. However, the effectiveness and durability of such a device entirely depends on the type of battery installed in the device. Therefore, the choice of power supply should be given special attention.

Advantages and disadvantages

High consumer demand and a large number of positive reviews about battery devices are due to a number of indisputable advantages of such models. Compared to network devices, cordless screwdrivers are completely autonomous and do not need an external power source. This allows you to carry out work in the adjacent territories, where it is technically impossible to stretch the carrying, as well as in the field.

In addition, the devices do not have a wire, which makes it possible to use them in hard-to-reach places where you cannot get close with a network tool.

Like any complex technical device, battery models have their weaknesses. These include a greater, in comparison with network models, weight, due to the presence of a heavy battery, and the need to periodically charge the battery.

In addition, the cost of some self-contained samples significantly exceeds the cost of devices operating from the network, which is often a decisive factor and forces the consumer to abandon the purchase of battery devices in favor of electrical ones.

Views

Today, cordless screwdrivers are equipped with three types of batteries: nickel-cadmium, lithium-ion and nickel-metal hydride models.

Nickel Cadmium (Ni-Cd)

They are the oldest and most widespread type of battery known to mankind for the last 100 years. The models are distinguished by their high capacity and low price. Their cost is almost 3 times lower than that of modern metal-hydride and lithium-ion samples.

The batteries (banks) that make up the common unit have a nominal voltage of 1.2 volts, and the total voltage can reach 24 V.

The advantages of this type include a long service life and high thermal stability of batteries, which allows them to be used at temperatures up to +40 degrees. The devices are designed for a thousand discharge / charge cycles and can be operated in active mode for at least 8 years.

In addition, with a screwdriver equipped with this type of battery, you can work until it is completely discharged, without fear of a decrease in power and quick failure.

The main disadvantage of nickel-cadmium samples is the presence of a "memory effect", due to which it is not recommended to charge the battery until it is completely discharged... Otherwise, due to frequent and short-term recharging, the plates in the batteries begin to deteriorate and the battery quickly fails.

Another significant drawback of nickel-cadmium models is the problem of disposal of used batteries.

The fact is that the elements are highly toxic, which is why they require special conditions for conservation and processing.

This led to a ban on their use in many European countries, where strict control has been established to maintain the cleanliness of the surrounding space.

Nickel Metal Hydride (Ni-MH)

They are more advanced, in comparison with nickel-cadmium, battery option and have high performance.

The batteries are lightweight and small in size, which makes it much easier to work with a screwdriver. The toxicity of such batteries is much lowerthan the previous model, and Although the "memory effect" is present, it is rather weakly expressed.

In addition, the batteries are characterized by a high capacity, a durable case and are able to withstand more than one and a half thousand charge-discharge cycles.

The disadvantages of nickel-metal hydride models include low frost resistance, which does not allow them to be used in conditions of negative temperatures, fast self-discharge and not very long, in comparison with nickel-cadmium samples, service life.

In addition, the devices do not tolerate deep discharge, take a long time to charge and are expensive.

Lithium-ion (Li-Ion)

Batteries were developed in the 90s of the last century and are the most modern accumulator devices. In terms of many technical indicators, they noticeably outperform the two previous types and are unpretentious and reliable devices.

The devices are designed for 3 thousand charge / discharge cycles, and their service life reaches 5 years. The advantages of this type include the absence of self-discharge, which allows you not to charge the device after long-term storage and immediately start working, as well as high capacity, light weight and compact dimensions.

The batteries have no "memory effect" at all, which is why they can be charged at any discharge levelwithout fear of power loss. In addition, the devices charge quickly and are free of toxic substances.

Along with many advantages, lithium-ion devices also have weaknesses. These include high cost, lower service life and low impact resistance compared to nickel-cadmium models. So, under strong mechanical shock or dropped from a great height, the battery may explode.

However, in the latest models, some technological flaws have been eliminated, so the device has become less explosive. So, a controller for heating and battery charge level was installed, which made it possible to completely exclude an explosion from overheating.

The next disadvantage is that batteries are afraid of deep discharge and require regular monitoring of the charge level. Otherwise, the device will begin to lose its working properties and quickly fail.

Another drawback of lithium-ion models is the fact that their service life does not depend on the intensity of use of the screwdriver and the cycles it has worked out, as is the case with nickel-cadmium devices, but solely on the age of the battery. So, after 5-6 years even new models will be inoperative, despite the fact that they have never been used. That's why the purchase of lithium-ion batteries is reasonable only in cases where regular use of a screwdriver is expected.

Design and specifications

The battery is rightfully considered one of the main components of the screwdriver, the power and duration of the device depends on how high its operational properties are.

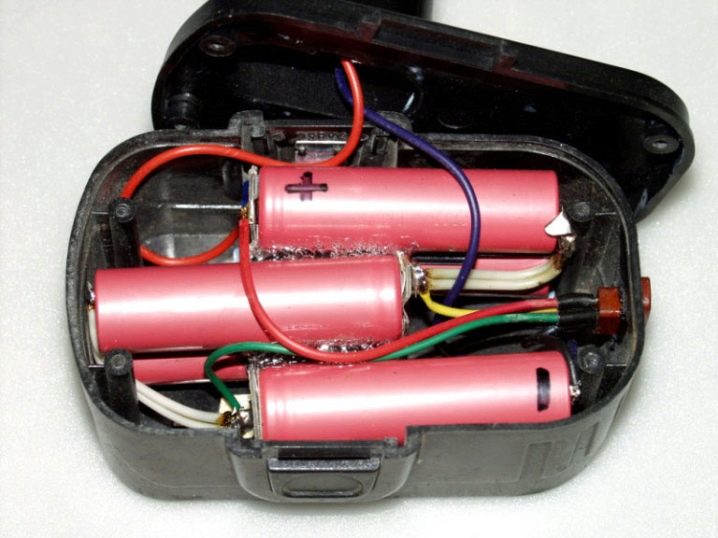

Structurally, the battery is arranged quite simply: the battery case is equipped with a cover that is attached to it by means of four screws. One of the hardware is usually filled with plastic and serves as proof that the battery has not been opened. This is sometimes necessary in service centers when servicing batteries that are under warranty. A garland of batteries with a series connection is placed inside the case, due to which the total voltage of the battery is equal to the sum of the voltage of all batteries. Each of the elements has its own marking with operating parameters and model type.

The main technical characteristics of rechargeable batteries for a screwdriver are capacity, voltage, and full charge time.

- Battery capacity measured in mAh and shows how long the cell is able to supply the load when fully charged. For example, a capacity indicator of 900 mAh indicates that at a load of 900 milliamperes, the battery will be discharged in one hour. This value allows you to judge the potential of the device and correctly calculate the load: the higher the battery capacity and the better the device holds a charge, the longer the screwdriver will be able to work.

The capacity of most household models is 1300 mAh, which is enough for a couple of hours of intensive work. In professional samples, this figure is much higher and amounts to 1.5-2 A / h.

- Voltage It is also considered an important technical property of the battery and has a direct impact on the power of the electric motor and the amount of torque. Household models of screwdrivers are equipped with medium power batteries of 12 and 18 volts, while batteries for 24 and 36 volts are installed in powerful devices. The voltage of each of the batteries that make up the battery pack varies from 1.2 to 3.6 V and depends from the battery model.

- Full charge time indicates how long it takes for the battery to fully charge. Basically, all modern battery models are charged quickly enough, in about 7 hours, and if you only need to recharge the device a little, then sometimes 30 minutes is enough.

However, with short-term charging, you need to be extremely careful: some models have the so-called "memory effect", which is why frequent and short recharges are contraindicated for them.

Selection Tips

Before proceeding with the purchase of a battery for a screwdriver, it is necessary to determine how often and in what conditions the tool is planned to be used. So, if the device is purchased for occasional use with minimal load, then there is no point in purchasing an expensive lithium-ion model. In this case, it is better to opt for time-tested nickel-cadmium batteries, with which nothing will happen during long-term storage.

Lithium products, regardless of whether they are in use or not, must be kept charged while maintaining at least 60% charge.

If the battery is chosen for installation on a professional model, the use of which will be constant, then in this case it is better to take "lithium".

When buying a screwdriver or a separate battery from your hands, you must remember about the property of lithium-ion models to age in accordance with their age.

And even if the instrument looks like new and has never been turned on, the battery in it is most likely already inoperative. Therefore, in such situations, you should choose only nickel-cadmium models or be prepared for the fact that the lithium-ion battery will have to be changed soon.

Regarding the operating conditions of the screwdriver, it should be borne in mind that if the tool is chosen for work in the country or in the garage, then it is better to opt for "cadmium"... Unlike lithium ion samples, they tolerate frost much better and are not afraid of blows and falls.

For infrequent indoor work, you can buy a nickel-metal hydride model.

They have a large capacity and are well proven as a household assistant.

Thus, if you need an inexpensive, hardy and durable battery, then you need to choose nickel-cadmium. If you need a capacious model that can turn the engine for a long time and powerfully - this is, of course, "lithium".

Nickel-metal-hydride batteries in their properties are closer to nickel-cadmium, therefore, for operation at positive temperatures, they can be chosen as a more modern alternative.

Popular models

Currently, most power tool companies manufacture batteries for drills and screwdrivers. Among the huge variety of different models, there are both popular world brands and inexpensive devices from little-known companies. And although due to high competition, almost all products on the market are of high quality, some models should be highlighted separately.

- The leader in the number of approving reviews and customer demand is Japanese Makita... The company has been manufacturing power tools for many years and, thanks to the accumulated experience, supplies only high-class products to the world market. Thus, the Makita 193100-4 model is a typical representative of nickel-metal hydride batteries and is famous for its high quality and long service life. The product belongs to the high-price category batteries. The advantage of this model is a large charge capacity of 2.5 A / h and the absence of a "memory effect". The battery voltage is 12 V, and the model weighs only 750 g.

- Battery Metabo 625438000 is a lithium-ion battery and has incorporated all the best characteristics of this type of product. The device does not have a "memory effect", which allows you to charge it as needed, without waiting for a complete discharge of the battery. The voltage of the model is 10.8 volts, and the capacity is 2 A / h. This allows the screwdriver to work for a long time without recharging and to be used as a professional tool. Installing a replaceable battery into the device is very easy and does not cause difficulties even for those users who are replacing the battery for the first time.

The peculiarity of this German model is its low weight, which is only 230 g. This significantly lightens the screwdriver and puts it on the same level as the mains appliances in terms of comfort of use.

In addition, such a battery is quite inexpensive.

- Nickel-cadmium model NKB 1420 XT-A Charge 6117120 produced in China using Russian technology and is analogous to Hitachi EB14, EB1430, EB1420 batteries and others. The device has a high voltage of 14.4 V and a capacity of 2 A / h. The battery weighs quite a lot - 820 g, which, however, is typical for all nickel-cadmium models and is explained by the design features of the batteries. The product is distinguished by the ability to work on a single charge for a long time, the disadvantages include the presence of a "memory effect".

- Cube battery 1422-Makita 192600-1 is another member of the popular family and is compatible with all screwdrivers of this brand. The model has a high voltage of 14.4 V and a capacity of 1.9 A / h. Such a device weighs 842 grams.

In addition to well-known brand models, there are other interesting designs on the modern market.

Thus, the Power Plant company has launched the production of universal batteries that are compatible with almost all popular brands of screwdrivers.

Such devices are much cheaper than native batteries and have proven themselves quite well.

Operation and maintenance

To increase the service life of batteries, as well as to ensure their correct and stable operation, a number of simple rules must be followed.

- Work with screwdrivers equipped with nickel-cadmium batteries must be continued until the battery pack is completely discharged. It is recommended to store such models only in a discharged state.

- In order for NiCd devices to quickly "forget" the unwanted charge level, it is recommended to run them several times in a "full charge - deep discharge" cycle. In the process of further work, it is extremely undesirable to recharge such batteries, otherwise the device may again “remember” unnecessary parameters and in the future will “turn off” exactly at these values.

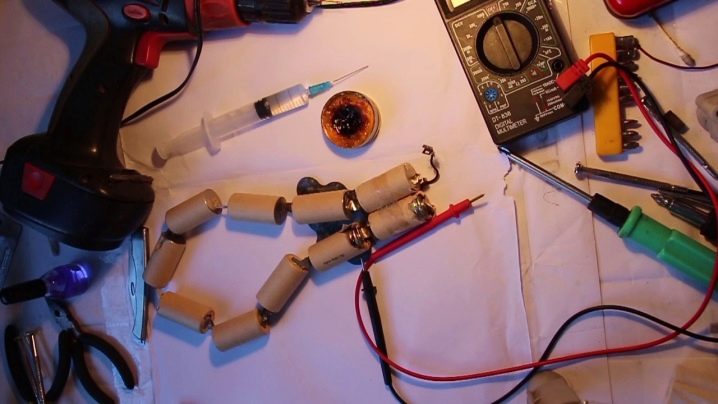

- A damaged Ni-Cd or Ni-MH battery bank can be restored.To do this, a current is passed through it in short pulses, which must be at least 10 times higher than the capacity of the battery. During the passage of the pulses, the dendrites are destroyed and the battery is restarted. Then it is "pumped" through several cycles of "deep discharge - full charge", after which they begin to use it in working mode. The recovery of a nickel-metal hydride battery follows the same scheme.

- The restoration of lithium-ion batteries by the method of diagnostics and pumping of a dead cell is impossible. During their operation, decomposition of lithium occurs, and it is absolutely impossible to compensate for its losses. Defective lithium-ion batteries must only be replaced.

Battery replacement rules

To replace the cans in a Ni-Cd or Ni-MH battery, you must first remove it correctly. To do this, unscrew the fastening screws, and in more budget models that are not equipped with a removable structure, gently pry the block with a screwdriver and remove the battery.

If the body is glued into the handle of the screwdriver, then using a scalpel or a knife with a thin blade, disconnect the block around the entire perimeter, and then pull it out. After that, you need to open the lid of the block, unsolder or bite off all the cans with pliers from the connecting plates and rewrite the information from the marking.

Typically, these battery models are equipped with batteries with a voltage of 1.2 V and a capacity of 2000 mA / h. They are usually available in every store and cost about 200 rubles.

It is necessary to solder the elements to the same connecting plates that were in the block. This is due to the fact that they already have the required cross-section with resistance, which is necessary for the correct functioning of the battery.

If it was not possible to save the "native" plates, then copper strips can be used instead. The section of these strips must be absolutely identical to the section of the "native" platesotherwise the new blades will become very hot during charging and trigger the thermistor.

Soldering iron power when working with batteries should not exceed 65 W... Soldering must be done quickly and accurately, without allowing the elements to overheat.

The battery connection must be consistent, that is, the "-" of the previous cell must be connected to the "+" of the next. After the garland is assembled, a full charging cycle is carried out and the structure is left alone for a day.

After the specified period, the output voltage on all batteries must be measured.

With proper assembly and high-quality soldering, this value will become the same on all elements and will correspond to 1.3 V. Then the battery is assembled, installed in a screwdriver, turned on and held under load until it is completely discharged. Then the procedure is repeated, after which the device is recharged and used for its intended purpose.

All about batteries for screwdrivers - in the video below.

The comment was sent successfully.