Mechanized plastering of walls: pros and cons

Plaster is a versatile way to prepare walls for decorative finishing. Today, for such work, many formulations are used, which are rather difficult to apply by hand. To speed up this process, many professionals use automated devices. This approach has many nuances and advantages that you need to know about in advance.

Peculiarities

Mechanized plastering is a relatively new method of applying mortar to walls. It is based on the use of special devices capable of supplying the mixture under a certain pressure through special pipelines.

Technically, this procedure involves the use of various types of motors and compressors.

But the quality of mechanical application to walls depends on several criteria:

- Surface adhesion. Some types of walls cannot be covered with plaster without preliminary preparation. For such work, concrete, brick or walls from various types of aerated blocks are perfect.

- The consistency of the solution. This factor is one of the most important. The mixture should not be too thick, as this will increase the load on the engines and may lead to engine failure.

Machine application is much better than hand plastering.

The classical approach is relatively time-consuming. At the same time, the old plaster already dries, while the new one has not yet gained strength.

With the help of automatic application, it is possible to obtain an almost identical layer of the solution, with which it is much easier to work in the future.

Mechanized plaster is a versatile approach that allows you to treat various types of surfaces:

- walls and ceiling;

- door or window slopes;

- decorative arches;

- external walls of buildings.

Machining is a versatile way to obtain a high-quality surface in a relatively short time.

Advantages and disadvantages

Mechanized plasters today are gradually replacing the manual application of mortars. This is due to several significant advantages of such works:

- High performance. The modern market is represented by automatic devices capable of using at least 1 cubic meter. m solution per hour. Depending on the thickness of the layer, walls with an area of up to 40-60 m2 can be easily plastered in one shift.

- Application quality. Plastering "guns" apply mortar much better than normal scooping. Initially, the surface is almost flat and requires only minor adjustments, which can also be done with automated systems.

- Formation of strong adhesion of mortar and base. This is achieved due to the uniform distribution of layers and a uniform feed rate of the solution. With this approach, the solution can penetrate almost all the cracks, filling them almost completely. It is almost impossible to achieve this using manual methods.

- Relatively low costs. Several people can apply the mixture. To achieve such productivity manually, it would be necessary to increase the number of employees several times, which would greatly affect the financial costs.

- Reduced plaster costs. This is achieved due to the fact that the mixture is evenly applied to the wall.Almost all of the product is used for its intended purpose, allowing you to cover a much larger area than with a manual approach. According to user reviews, automatic devices can reduce consumption by about 1.5 times.

- Relatively low cost of plasters. This indicator may differ depending on the manufacturer and the structure of the wall surface on which the compounds are applied.

- No filling. The cement mortar fills all the cracks well, which excludes the pre-treatment of the walls.

The use of a mechanical approach to plastering can simplify repair tasks. But mechanized plastering is not a universal method, as it has several significant disadvantages:

- High cost of equipment. Therefore, in household construction, this method is quite rare. But if you are engaged in this activity professionally, then the tool will pay for itself very quickly. For one-time plastering, it is better to hire specialists who already have all the necessary equipment.

- High device performance requires a constant supply of water and mixtures. Therefore, it is advisable to have a water connection so as not to stop the process halfway.

- Strict adherence to recommendations when preparing mixtures. If you decide to add some kind of impurity yourself, then there is no guarantee that the device will be able to effectively apply the resulting solution.

Modern mechanized plastering machines are a versatile solution. This led to their widespread distribution at many construction sites, where wall processing can be carried out at several points at once.

Mixes

The main parameter on which the quality of the treated surface depends is plaster mixes. They can be conditionally divided into dry and wet. The second type of product is used by large construction companies. They purchase a ready-made mixture, which is delivered to them using concrete mixers. But the main ones on the market today are dry mixes, which allow you to get plaster yourself.

Depending on the composition, dry foods can be divided into 2 large groups:

- Gypsum plasters. The main connecting element here is ordinary gypsum. Since the material absorbs moisture very well, it is advisable to use it indoors only when the air humidity is not high.

A unique property of gypsum plasters is a high drying rate.

This allows you to get a high-quality surface for decorative finishing within a few days after application.

The mixtures have high porosity, reducing the consumption of mortar several times compared to cement compositions. When applied with automatic devices, an almost perfectly flat surface can be obtained that requires minimal processing.

- Cement-sand plasters. Versatile mixes that can be applied to almost any surface. Since the substance tolerates temperature extremes and exposure to water well, many use it to decorate the facades of houses.

If you are planning to build a pool, then this type of plaster will also be the best option.

The disadvantages of these products can be considered long drying and uneven structure of the top layer. Therefore, after application, the plaster must be additionally smoothed out in order to obtain an even and solid base.

The modern market offers many types of dry and semi-dry mixtures. Among all this diversity, several popular brands should be distinguished:

"Prospectors"

Gypsum-based mixture with high adhesion properties. It is intended for application on various types of surfaces, among which brick, concrete and foam block are optimal.

Among the positive qualities, one can single out the ability of the solution to pass air and retain heat inside the house.

The manufacturer indicates that the composition can be used as finishing mixes.

"Osnovit"

Another representative of gypsum plasters, perfect for interior decoration. The fine-grained structure of the components allows the mortar to be applied to walls in a layer about 1 cm thick. In this case, the product consumption will not exceed 9 kg / m. The plaster is suitable for treating walls and ceilings.

The material is also distinguished by high vapor permeability and good thermal insulation characteristics.

Knauf

The company is one of the leaders in the production of mixtures for finishing various surfaces. It should be noted its gypsum plasters, which contain various polymer impurities.

Among the features of the material, one can single out high plasticity, as well as adhesion to various surfaces.

The color range of the mixes includes not only gray, but also pink shades.

Volma

One of the leaders in domestic production. Produces high-quality gypsum plasters for mechanized application.

In terms of technical characteristics, the products are practically not inferior to the products of the previous manufacturer. Among the features of the plaster, one can single out its fast drying.

The manufacturer claims that you can start grouting the walls after 4 hours after application.

After this treatment, the surface is already ready for painting or wallpapering. At the same time, the outer layer is practically indistinguishable from the bases covered with special putty compounds.

Please note that almost no one produces cement-based mixtures. Technically, this is not necessary, since it is quite easy to obtain such a plaster. It is necessary to mix high-quality sand and cement in certain proportions in order to obtain the desired consistency of the solution.

Equipment

Plastering is carried out by special mechanized devices. Depending on the method of supplying the solution, they can be divided into 2 main groups:

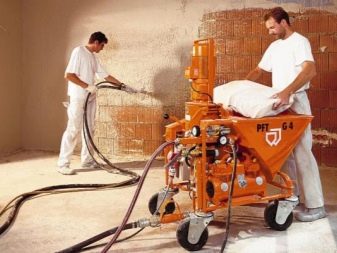

- Auger apparatus. The main element of the system is the auger, which is able to capture the solution and move it in a certain direction. These machines can be compared to classic meat grinders. But they are distinguished by great power and performance. A hose is connected to this system, which is supplied to the point of implementation of the work.

- Pneumatic devices Are relatively simple constructions. The main tool here is the hopper (bucket), to which the compressed air hose is connected. Atomization is carried out due to the high velocity of the gas, which pushes the solution through one or more holes. The disadvantage of such a device is that the plaster must be prepared separately and immediately in a large volume. Some devices are not convenient and practical. Therefore, their use is justified for living conditions.

All of these devices can be used to apply the mixture to walls or floors.

Let's consider in more detail the principle of operation of the auger apparatus:

- The solution is poured into a special mixing compartment. Please note that you can use both prepared foods and individual components. The amount of liquid and all other products must exactly correspond to the recommendations of the manufacturer or specialists.

- The system then feeds these components into the mixer. Inside it, mixing takes place over a period of time.

- When the composition is ready, the auger grabs it and feeds it into the hose. There, a high pressure is created, forcing the solution to move towards the exit. Once on the sprayer, the plaster comes out at a certain speed and adheres to the substrate.

Please note that all these processes are fully automated, and the operator is only required to connect to the water supply hose system and timely fill the components of the future solution.

Today, there are several popular proprietary mechanisms for applying plaster on the market:

- Knauf. The machines of this company are compact. Their main purpose is to apply plaster. But with their help, you can also paint.

- Bottlenose dolphin. The ShM-30 model can be considered a striking representative of this brand, which can work with various types of solutions. Therefore, with its help, you can not only plaster walls or ceilings, but also fill the floors.

- UShM-150 - a small mechanism for plastering, which is recommended to be used when leveling the bases is necessary. Some modifications can also work with paints.

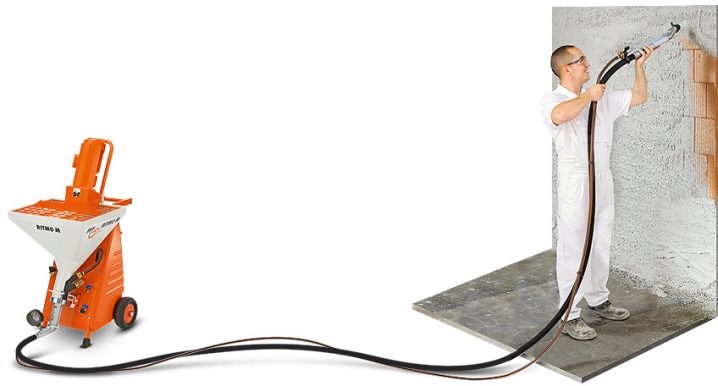

- PFT Ritmo - a modern device that can be used even in small spaces. The system is versatile, as it is intended not only for plastering, but also for puttying or painting.

Application process

The operation of automated machines is a relatively simple operation.

The technology for applying plaster using such devices consists of the following sequential stages:

- Surface preparation. It is necessary to apply solutions on relatively clean substrates. It is advisable to begin the preparation with the removal of deck grease, assembly glue and concrete build-ups.

- It is important that they do not form protrusions with a height of more than 1 cm. All brick and aerated concrete walls must be additionally primed. For this, experts recommend using deep penetration mixtures.

- If there are many slots on the surface of the base, then they must be additionally reinforced with a metal mesh. This should be done in accordance with the recommendations of specialists.

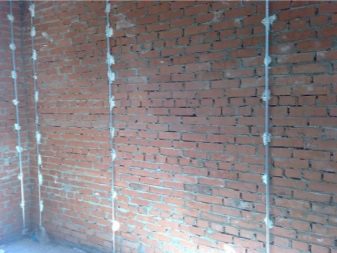

- Installation of beacons. They are needed to get a perfectly flat surface in one plane. This procedure is started by assessing the quality of the wall base. You can find out the deviations using a string and a long level.

- Having determined the maximum height of the protrusion on a particular plane, all beacons should be attached. They are fixed using the same solution. For this, several point bumps are placed on the surface, to which the lighthouse is attached.

- Equipment adjustment. If you are using a regular hopper, then you only need to properly prepare the solution. In the case of automatic machines, you must first set the required percentage of the components to be mixed. Some models provide the ability to change and work productivity.

- The next step is to connect a hose with water to the device. It is important to place all the components of the future plaster close to the mixers in order to speed up the whole procedure.

- Application of the solution. After starting the device, the mixture will begin to flow to the outlet valve. The screed should be formed keeping the system at a distance of 20-30 cm from the wall surface. Execution begins with sealing corners and joints, which should be carefully filled with a mixture. It is important that each next layer overlaps half of the previous one.

- Alignment. Immediately after application, the mortar should be leveled along the beacons using a long rule. After 30-50 minutes, you can start leveling with various types of graters. They allow you to get a flat, but not smooth surface. If you need a very high quality, then the hardened solution should be additionally putty.

Please note that this approach is very often used for cement renders. Gypsum mortars are more plastic and practical. After grouting, these surfaces can be immediately painted or coated with other finishing materials.

Advice

The quality of the plaster obtained with the help of mechanical devices is distinguished by high rates.

To achieve these characteristics, you should follow a few simple rules:

- Walls can be plastered only in rooms where the temperature does not drop below +5 degrees. Therefore, in winter, such tasks are carried out only in heated rooms, where it is possible to control the microclimate.

- The mixture should be applied from top to bottom. Please note that manually these operations are performed in reverse. If external facades are being processed, then they need to be additionally reinforced with a metal reinforcing mesh.

- In order to level the screed for painting or wallpaper, the plaster should be promptly processed and putty. It is advisable to do this 2 hours after applying the mixture. To simplify the task, pre-wet the material with water from a spray bottle and let it soak. This will soften the solution and allow you to distribute it evenly and easily.

- Use only high-quality mixtures of well-known manufacturers for work. Cheaper products do not always show themselves at a high level.

The technology for applying mechanized plaster is quite simple and requires only adherence to the rules and accuracy. Important here is the choice of a quality tool that allows you to apply plaster in a convenient way, and following clear stages of the process.

If you take into account all the recommendations, then the mechanically applied coating will be of high quality and durable.

How the mechanized plastering of walls is performed can be seen below.

The comment was sent successfully.