Drywall plaster: choice of mixture and application technology

Drywall appeared in the middle of the twentieth century, but it has only been widely used in the last two decades. Currently, it is used everywhere - for the construction of partitions, wall and ceiling cladding, the construction of various kinds of structures. However, not every master, let alone a beginner, knows how to process this material correctly.

Peculiarities

Drywall is a building material consisting of several layers:

- paper - there are two of them and they are located outside;

- gypsum - acts as an internal layer; to improve its properties, various fillers are added to it.

It is issued in the form of sheets, which can be:

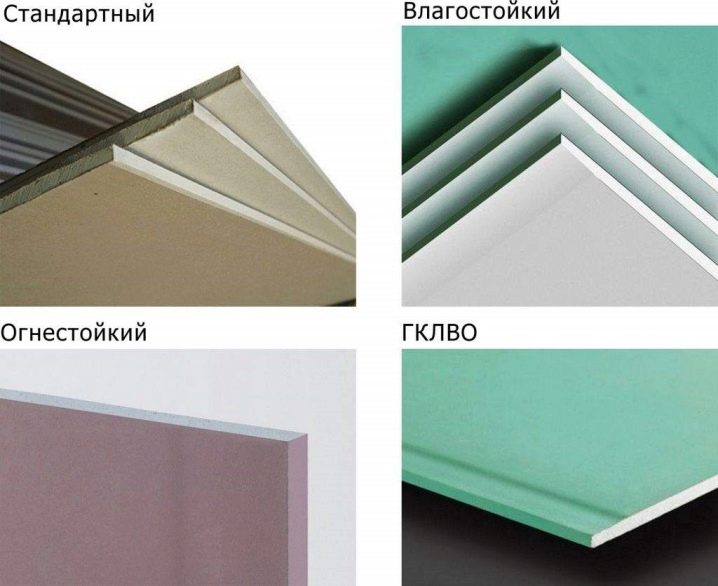

- conventional (GCR);

- moisture resistant (GKLV);

- fire resistant (GKLO);

- with increased strength (gypsum fiber - GVL).

Among the advantages of the material, the main one is that it can be used not only to create rectangular building objects, but also radius ones, with completely unthinkable shapes. It is multifunctional - it well hides architectural flaws (for example, deviations from a right angle by several degrees) and uneven walls and ceilings, ventilation communications, pipes and wiring. In addition, it is lightweight, flexible, environmentally friendly, reasonably good thermal insulation and fire resistance.

There are also disadvantages - fragility, poor sound insulation and the need to purchase a special fastening system.

At construction forums, there are lengthy discussions on the need to apply plaster to drywall structures. After all, in fact, they have the same functions - leveling and protecting walls from external influences. Moreover, they are very similar in composition. Professionals still emphasize that this should be done.

- First, the plasterboard surface is rarely left in its original form. And for the application of any decorative coating, a perfectly flat surface is needed.

- Secondly, when fixing drywall sheets, it is often necessary to dock and in order to do this, fasteners are needed. All caps and joints will be perfectly visible even under wallpaper and paint.

- Thirdly, it is necessary if you want to mask defects that have appeared during long-term operation.

- Fourthly, plaster is applied in the event that it is she who will be a decorative coating.

Choice of plaster

According to the purpose of the mixture, which can be applied to drywall, can be divided into three types:

- for general use (in a continuous layer) or for local use (as a mask for irregularities - dents, depressions and bulges);

- to create protection against moisture, cold, loud sounds and other manifestations of the environment;

- to create a decorative layer.

The first ones are applicable only for moisture resistant sheets. This is due to the fact that ordinary ones are deformed under the influence of water and steam. Therefore, not only should they not be placed in bathrooms, but also covered with water-based plaster. Of course, many experts note that the negative impact is contained by the primer. But in the repair business it is better not to risk it.

Conventional plaster can be subdivided into:

- Gypsum - it forms a white coating. Whiteness is often achieved through the addition of additives (asbestos and similar materials) that are bad for human health. However, it significantly saves time due to the ease of application.The disadvantages include the high cost, low strength and resistance to moisture, compared to other materials.

- Magnesian - also suitable for interior decoration. Differs in high indicators of strength. It does not crumble or burn. She has one significant drawback - the price.

- Cement-sand - suitable for decoration both inside and outside the building. Sometimes, to make the mixture more plastic, glue or lime is added to it. It is more difficult to apply than other types, but this drawback is fully compensated for by its affordable price, durability and long service life.

- Lime - used more often outside than inside. Among the advantages are naturalness, ease of use. This type has the lowest strength, therefore, in order to improve this indicator, cement is sometimes added to it.

It is these materials that are the basis for the so-called special plasters:

- Heat insulating. Foamed glass, polystyrene, vermiculite or perlite are added to the base of sand, cement and lime. The secret to keeping you warm lies in its special texture, which includes air bubbles.

- Soundproof. Additional components in this case are pumice, expanded clay, slag or vermiculite - they absorb sounds well.

- Waterproofing. Moisture resistance is ensured by the addition of polymers.

- X-ray protective. Enhances protection against radiation due to the barite included in the composition.

- Acid resistant. It is resistant to the action of chemicals, as it contains potassium glass and quartzite.

Decorative plaster is an alternative to wallpaper and some types of paints. In addition to external beauty, this mixture has a protective function. In addition, it is versatile and can be applied to any type of gypsum plasterboard, including conventional gypsum boards.

The composition of the mixture can be distinguished:

- Mineral. The most budgetary one, since it is based on the same cement. It retains its color well throughout the entire period of operation, but it is easily chipped off.

- Acrylic. More durable. But under the influence of sunlight it loses its brightness.

- Silicone. Plastic, easy to apply, moisture resistant.

- Silicate. Resistant to mechanical stress, as well as the action of fire, water and sunlight. It is durable, but inaccessible due to its high cost.

The surface of such plaster can be smooth or embossed, homogeneous or granular. The choice of color is practically unlimited, since any pigment from the building materials on the market can be added to the mixture.

Application process

Before plastering a wall or any other surface with a mixture, you need to pay attention to problem areas.

Let's analyze this process using the example of joints:

- First you need to choose a material. A putty is also suitable for seams. Deeper damage must be treated with plaster.

- The mixture is diluted with a mixer or by hand.

- The edges of the sheets are cut at an angle to create a chamfer. The resulting recess is primed.

- Next, apply the solution with a narrow spatula into the groove and level. Lay the reinforcing mesh on top and cover it with another layer.

- Smooth everything out with a wide trowel.

- After drying, irregularities must be wiped off with a brush or sandpaper.

Internal corners are handled the same way. For the outside, there are special mesh or metal profile corners. The caps of the self-tapping screws must be recessed in relation to the surface level. They are also first primed, and then putty.

Before gluing the wallpaper, such a coating is sufficient.

Before painting or laying tiles, plastering is mandatory:

- Two spatulas are required. A narrow solution is applied to a wide one.

- Directly apply the mixture to the wall with a wide spatula and level it.

- Layers should be as thin as possible. If in the end it is necessary to level out a large deviation from the level, then it is better to apply several thin layers than one, but thick one.

- The finishing layer is equal and checked by the rule.

- After drying, the surface must be sanded.

Arches and other structures with semicircular outlines are finished as follows:

- A primer is applied to the surface and a reinforcing profile or mesh is installed at the corners of the arch, fixed with nails or screws temporarily.

- With a small spatula, apply the mass between the cloves, pressing firmly.

- After hardening, take out the cloves and grind.

- Then you should proceed to the inner vault of the arch. To do this, take a wide spatula, put putty on it and smooth it with a thin layer over the designated surface. You can do the finishing coat right away, since there are no irregularities there.

Decorative plaster can be applied in different ways, but initially the wall should be primed in two coats and the base mix is applied thinly.

Then you need to do the following:

- To obtain any color, the plaster can be tinted in mass or covered with paint after all work is completed. To color the solution, you need to add color to it. And then apply the resulting decorative mass to the wall and distribute.

- Begin to form a relief. To do this, use rollers, spatulas, brushes, sponges and other improvised means. It all depends on what kind of effect you want to get in the end. Sometimes the texture begins to form directly during the application of the solution. Sometimes sprayers are required for application.

- After hardening, the surface is painted, covered with wax, or, conversely, part of the coating is removed with various devices. Again, it all depends on your imagination.

Tips and tricks:

- Before starting the manipulations, you need to think over and prepare the inventory, improvised means (ladder, additional light sources, extension cords). Do not forget about protective equipment (overalls, headwear, shoes, gloves).

- Only whole sheets are plastered, without holes. Since in places where the integrity is broken, the coating can penetrate into the inner layer of drywall. With such a deformation, it is better to immediately replace the sheet with a new one.

- Do not neglect the primer. Any coating fits better on it. And when applied to sheets, it also protects against swelling.

- The primer is applied with a roller. Alkyd, acrylic or phenolic bases are best suited in our case. They not only improve the properties of the gypsum board, but also save money.

- Before applying any type of coating, the surface must be thoroughly cleaned. This is especially true of gypsum dust, which remains in large quantities after the installation of gypsum plasterboards. To remove it, you need a good, preferably an industrial vacuum cleaner. As well as wetting the surface from a spray bottle. In addition to the dry mixture that needs to be diluted, there are ready-made solutions on sale.

- All solutions are prepared in portions. And the leftovers are hermetically sealed in containers.

- The solidification time of the solution is different for each manufacturer. It must be taken into account when it is required to apply the next layer only after the previous one has completely dried. It is important to follow the instructions on the package in everything.

- The indoor climate contributes to the speedy completion of the work and the improvement of the quality of the cladding. It should not be hot or cold. Constant air exchange is required.

For plasterboard plaster, see the video below.

The comment was sent successfully.