Vernier caliper: types, device, error and choice

Vernier caliper is a universal measuring tool and is in great demand by controllers, technologists, designers, turners, milling cutters, locksmiths, auto mechanics and carpenters. The wide popularity of the device is due to its ease of use, large measurement range and highest accuracy.

What it is?

The caliper owes its appearance primarily to the industrial revolution of the 18th-19th centuries, during which began a massive transition to the mechanization of manual labor and industrialization. However, the prototype of a modern measuring instrument, which was widely used in mechanical engineering of that period, appeared two centuries earlier, namely in the middle of the 16th century. At that time, rulers made of wood and equipped with movable jaws began to appear in turning workshops on cutting machines.

A little later, namely in 1631, by the mathematician P. Vernier, the instrument was modified and equipped with an additional measuring scaleallowing you to perform more accurate measurements with minimal error. The caliper created by him has survived to this day practically unchanged and in professional circles has received the popular name "Columbic".

The term appeared in Soviet times, when Columbus was the main manufacturer and supplier of measuring equipment to the domestic market.

Today, the main purpose of a caliper is to carry out high-precision measurements that can be made both inside the measured objects and outside. In addition, it is used to measure the depths of holes, steps and curved elements. The tool is simply necessary for measuring the outer and inner diameters of objects of round and cylindrical shapes., such as bolts and nuts, and to determine the internal parameters of ditches, recesses and crevices. The principle of operation of the Columbus is to determine the size by the method of movement of a special measuring frame, freely moving along the bar, with a scale applied to it.

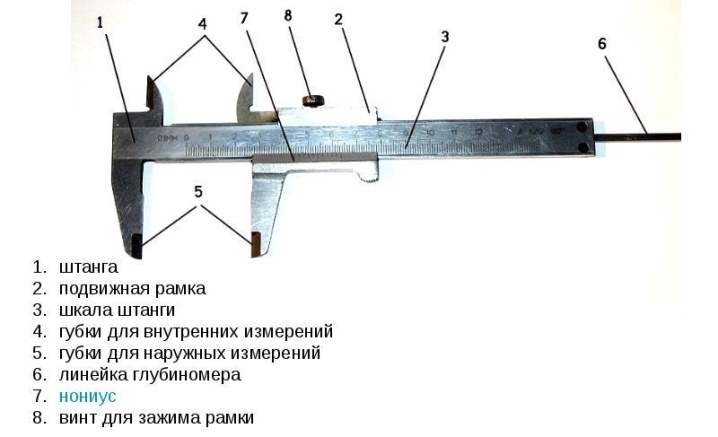

What does it consist of?

The caliper has a simple device, looks rather unpretentious and consists of several components.

- Ruler bar with a scale applied is the main structural element and determines the maximum measurement value. The longer the rod, the wider the measurement range.

- The measuring frame is represented by the moving part of the tool and is able to move easily along the main boom. The presence of a special scale - vernier with a step of 0.1 mm - and the use of the technique of alignment of divisions make it possible to obtain measurements with an accuracy of a fraction of a millimeter. A fixing screw and a spring are located on the inside of the frame, thanks to which the frame is tightly pressed against the bar and does not skew when moving along a fixed ruler. On some models, the vernier is replaced by a dial or small digital display, depending on the caliper model.

- The jaws are important parts of the device, which are movable and stationary. The former are included in the design of the movable frame or are rigidly fixed on it, the latter are part of the bar and are absolutely static. The movable and fixed jaws are located opposite each other and when the measuring frame is moved, they are in close contact.In this case, the zero marks of the barbell and vernier scale coincide. According to their functional purpose, the sponges are divided into one-sided (allowing measurements only from the outside) and two-sided (also intended for internal measurements).

- Pull-out bar is a structural part of the measuring frame and is designed to measure the depth of holes and grooves.

A description of a caliper would be incomplete without considering the materials from which it is made.

In most cases, for the production of particularly accurate measuring instruments, carbon and stainless steel grades are used, as well as its low-alloyed tool grades 9ХС and ХВГ.

To facilitate the design of modern calipers, composite compositions based on carbon fibers and polymer resins began to be used as materials of manufacture, as well as to include plastic elements in the design.

Views

At the moment, there are three design varieties of calipers, differing in the magnitude of the error, device and measurement technique. Regardless of the type, the tools do an excellent job of internal and external measurements of parts., but differ only in ease of use, speed of measurements and price.

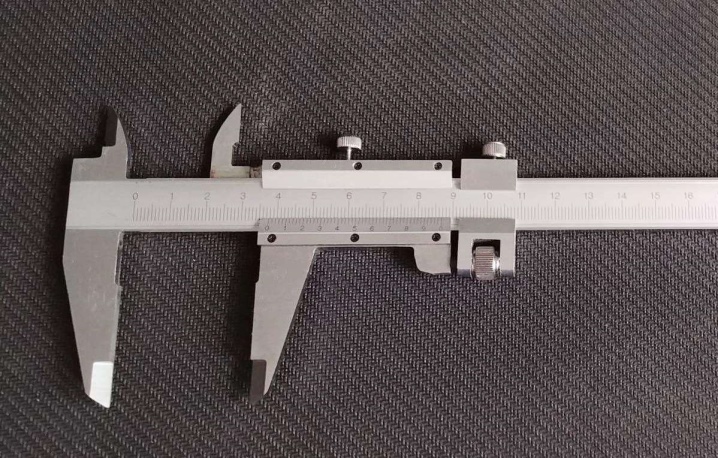

Vernier (analog)

This type of Columbus is a classic version of the instrument. It consists of a bar and a movable frame with a vernier. The device is distinguished by its simplicity of design and quite affordable cost. So, The simplest vernier model with one-sided jaws and a depth gauge can be purchased for 400 rubles.

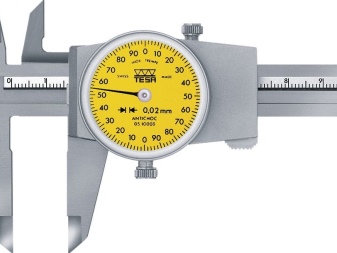

Dial (pointer)

On calipers of this type, the vernier is replaced by a dial on which a movable hand instantly displays the measurement results. When using such devices, no calculations are required, which makes their operation convenient and simple.

The arrow models are slightly more expensive than analog ones: for example, the simplest model will cost at least 1,700 rubles.

Digital

Calipers of this type are equipped with digital liquid crystal displays, which allows obtaining high-precision measurements. Such models are additionally equipped with a rechargeable battery, have an on / off button and are able to measure not only in millimeters, but also in inches. The most inexpensive digital instrument can be purchased within 1000 rubles.

Calipers of all types are produced in strict accordance with GOST 166-89 and are marked accordingly.

- SHTs-1 is a tool that is characterized by two-sided placement of jaws and is intended for external and internal linear measurements. The device is also equipped with a depth gauge and is considered the most popular caliper model.

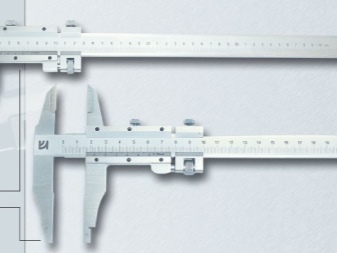

- SHTs-2 also has two-sided placement of jaws, and in addition to internal and external linear measurements, it can be used for marking. For this, the device is equipped with a micrometer feed frame, which allows you to evenly and accurately mark surfaces.

- SHTs-3 is a tool with one-sided jaw placement and is intended for internal and external linear measurements.

- ShTsK - vernier caliper, has a circular scale and allows measurements with high accuracy and speed.

- ШЦТ-1 represented by a tool with one-sided jaw placement and is characterized by increased wear resistance. The device is made of hard alloys and is capable of measuring not only linear dimensions, but also depth.

- SCC - electronic digital model, which is distinguished by high measurement accuracy and modern appearance.

In addition to models manufactured in accordance with GOST 166-89, there are instruments on the domestic market of measuring equipment made in accordance with technical conditions 3933-145-00221072-2003.

Such samples include:

- calipers ShTsS-200made of corrosion-resistant steel and capable of measuring stepped surfaces, depths and protrusions;

- model ShTSSU-200, which is a variation of the previous version, made using structural and tool steel;

- appliance ШЦГ-200, also a type of ShTsS-200, equipped with a depth gauge and made of anti-corrosion steel;

- model SCCS, which is a modern digital mechanism, which has the ability to change the measurement value from millimeters to inches and display the measurement results to external devices located at a distance of up to 70 m from the device;

- calipers SCR, designed for marking work on various objects and surfaces, and the presence of sharpened carbide jaws allows you to outline the marking directly on hard surfaces.

In addition to the considered typical models designed for linear internal and external measurements, as well as determining the depth, there are several devices on the market that have a narrower specialization.

They are used to solve problems that a conventional instrument is unable to cope with, and are classified as professional measuring equipment:

- the SCCT model is designed to measure the inner and outer diameters of pipes, which is why it is often called a pipe model;

- the ShTSTsD device is capable of measuring the thickness of various parts with numerous protrusions;

- vernier caliper ШЦЦП is used to determine the tread depth of tires and is often used in tire shops;

- ShTSTsM tool is designed to measure center-to-center distances between adjacent parts of complex mechanisms;

- the PShV track device is designed for measuring the railroad bed, belongs to the category of a highly specialized tool and costs more than 20,000 rubles;

- Calipers for determining the thickness of the brake discs allow you to determine the degree of wear without removing the wheels.

Specifications

Despite the wide variety of varieties on the market, the main technical characteristics of the tool are common to all of its types and are represented by such parameters as the maximum measurement limit, the stroke of the jaws, the permissible error and the dimensions of the products.

Measurement limits

This parameter shows the maximum measurement size and is always indicated on the marking of the caliper. For example, device ШЦ-1 125 is able to measure distances from 0 to 125 mm, and for larger models, such as ШЦ-3 630, the measurement limit begins not from zero, but from 250 mm and ends at 630 mm.

The tool marked ШЦ-3 4000 is capable of working with large objects and has a measurement range from 2000 to 4000 mm.

Extension of the jaws when measuring dimensions

This parameter also depends on the caliper model. For example, for model ШЦ-1, it should be at least 40 mm for external measurements (lower jaws) and at least 17 mm for internal measurements (upper jaws)... In this case, the ShTs-3 4000 device, intended exclusively for external measurements, the extension of the jaws cannot be less than 150 mm.

Allowable error

The accuracy class of instruments with vernier is limited to a division of 0.05 mm, since a finer gradation is practically not perceived by human vision and can lead to an error in calculations. Electronic digital devices are equipped with a division scale of 0.01 mm and are more accurate mechanisms... The error rates depend on the accuracy class of the device. For example, a class 2 model is capable of measuring a drill diameter of 5.7 or 5.8 mm, and a first class product can easily determine a size of 5.75 mm.

The reasons for even a slight increase in the measurement error can be the error of the tool itself, poor quality of the measured part, the presence of burrs, low-quality metal processing, deviations of the depth gauge from a strictly vertical position, loose pressing of the jaws to the object and poor fixation of the carriage with a screw.

The weight

This parameter depends entirely on the type of caliper and varies from 125 g to 9 kg. However, this weight is typical for household and small professional models.

Devices with a measuring range of up to 5000 mm often weigh more than 35 kg.

Dimensions (edit)

The size of the instrument depends on its type, purpose, measuring range and varies from 12.5 cm to several meters.

Verification method

Calibration of measuring instruments, as well as their production, is carried out in accordance with the standards of GOST 8.113-85. Control and measuring manipulations are carried out in special laboratories and performed on ultra-precise machines. However, you can perform the simplest caliper calibration at home. To do this, the tool is thoroughly cleaned of dirt, dust, adhered sawdust, metal shavings and lubricants, and then wiped dry with a clean cloth. Then the jaws of the caliper are brought down to the stop and watch the position of the zero strokes.

If the device is adjusted correctly, then the risks should match. Otherwise, it is necessary to contact a specialized center, where they will calibrate and adjust the device, on the basis of which a certificate of the established form will be issued. With regular use of a caliper, verification is performed at least once a year. If the metal of the working jaws is worn out, the tool becomes unusable and must be replaced with a new one. To increase the service life of the device, it is necessary to keep it clean and store it only in a case or case.

These requirements are due to the fact that even barely visible dents and scratches negatively affect the measurement accuracy and increase the error.

Manufacturers overview

The modern market for measuring instruments presents a wide range of calipers. Below are the best manufacturers according to the version of online stores, whose products are highly accurate and meet all modern requirements.

- Japanese company Mitutoyo has been producing calipers and other measuring equipment since 1934 to the present day. The assortment of the enterprise includes both simple vernier models and high-tech digital samples powered by solar panels.

- No less well-known company Shahe is also a recognized leader in the production of measuring equipment. The company's products are represented by models of all types, including digital electronic models and mechanical versions with a vernier scale.

- Calipers of the German brand Matrixmade in China are also in high demand among amateurs and professionals. The company's products are of high quality, wide range and reasonable prices. For example, an ultra-precise electronic pointer model with a depth gauge can be bought for only 1600 rubles.

- Instruments of the Russian brand "Kolibron"manufactured at a plant in China, are distinguished by a wide price range and consumer availability. The simplest model of the 1st accuracy class of the vernier type can be purchased for only 800 rubles. The products comply with the state standard 166-89 and fully meet modern quality and reliability requirements.

- Intertool from China delivers accurate and durable tools to the market. The company is engaged in the production of analog, dial and digital devices at prices much lower than those of competitors. This allows you to purchase a strong and accurate instrument for little money, which will reliably serve for more than one year.

- Young Russian enterprise "Zubr" started to engage in the production of measuring instruments quite recently, but in a short time it attracted the attention of both amateurs and professionals. The company has its own design office, which employs highly qualified specialists, and the tests of the manufactured devices are carried out in its own laboratory. The most inexpensive caliper with a length of 12.5 cm and weighing only 140 g can be purchased for 700 rubles, while an electronic digital model will cost 4,300 rubles.

Selection Tips

The acquisition of any measuring instrument is a very important and responsible business, therefore, its choice must be approached with special care. The first thing that you need to pay attention to when buying a device is the accuracy class and the conditions in which the tool is supposed to be used.

So, if a vernier caliper is needed to measure parts up to 300 mm in size for domestic purposes, then the best option would be a simple analog model ШЦ-1 with an appropriate measurement limit.

When buying a caliper designed for fine jewelry work, it is better to focus on short miniature samples 12-15 cm long. It is much more convenient for them to measure small objects without fear of damaging their surfaces.

If in the first place is the convenience of the work performed, as well as the speed of measurements, then it is better to opt for an electronic-digital or dial-pointer model. As for the accuracy class, a device with a readout of 0.1 mm is quite enough for domestic use, and for professional samples a much higher accuracy is required: the reading scale on such devices should have a step of 0.05, 0.02 and even 0.01 mm.

The next important criterion will be the choice of the manufacturer. Experts recommend purchasing products of well-known brands, which will act as a guarantor of the reliability, accuracy and high quality of measuring instruments. If measurements are planned to be made in difficult external conditions, it is better to purchase a device on which the scale will be engraved on the metal, and not painted with paint. The best professional models are German, Japanese and Swiss models, which, in principle, cannot be cheap. But such a caliper will last more than a dozen years and will be inherited by the grandchildren.

At the time of purchase, you should check the availability of accompanying documentation indicating the accuracy class and steel grade, and also make sure that there is no play between stationary and moving parts. Besides, the zero marks of both scales with tightly pressed jaws must necessarily coincide... In case of incorrect operation of the tool, too tight or, on the contrary, easy movement of the measuring frame and jaws, as well as in the presence of defects and damage, the purchase of the device should be abandoned.

How to use a caliper, see below.

The comment was sent successfully.