What is fine-line veneer and where is it used?

One of the latest developments in the interior door and furniture industry is a variation of the natural finish - fine-line veneer. Although the technological process of creating a product itself is much more laborious and overhead, it is in great demand due to its low price, excellent aesthetic characteristics. The coating has been used successfully for covering doors, furniture sets and other interior decoration items.

What it is?

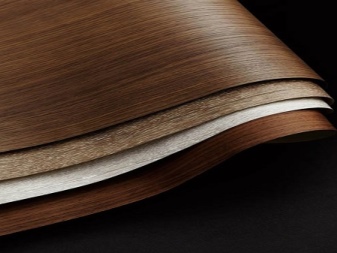

Most experts say that fine-line veneer is a good alternative to ordinary veneer, with a good imitation of valuable wood species. Although the relief of the surface of this veneer is similar to plastic, by its nature it is a natural and not a synthetic material that has many advantages and a more affordable price, if compared, for example, with the price of veneer from expensive species. The name of the material comes from the English combination of two words fine-line, which means "fine (excellent) line".

One of the advantages of this material is the widest color palette, fine-line lends itself perfectly to decorative and artistic processing. The generally accepted finishing methods are excellent for the application of the material. In all respects, fine line should be considered a reconstructed (or engineered) veneer made from inexpensive wood species.

The technological process of creating veneer determines its coloring, which, as a result, gives the finished product the appearance of a first-class stylization for expensive wood species.

Advantages and disadvantages

If you put fine-line on the same board with PVC films or other similar facing materials, then it significantly surpasses these materials. We have already learned what the fine-line veneer is, now it remains to consider its pros and cons in order to specifically make sure of the need for this product.

The advantages include a number of important points.

- Ecologicaly clean. Due to the fact that more than 92% of the texture is allocated to natural wood, the material is classified as environmentally friendly. Moreover, its production does not cause any particular harm to nature, since the material is produced from fast-growing tree species.

- Quite good aesthetic performance. As mentioned above, the canvases have a plastic-like surface, since there are no roughness or knots on it. After processing, the surfaces look fashionable and expensive.

- Plastic. Due to the bending structure and high plasticity parameters, the sheets are able to take different geometric configurations and restore their original size and shape after deformation. Sheets are used to refine almost any surface (door cladding, columns, table tops, decorative elements).

- Price. In comparison with classic natural veneer, the fine-line line is relatively inexpensive.

- Stability and operational period. The material is highly resistant to temperature fluctuations. In addition, the finish works well in places with high levels of humidity.

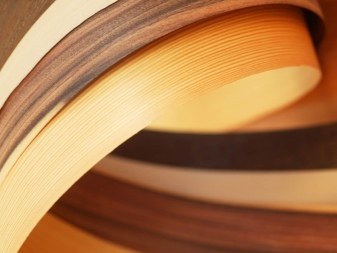

- An impressive assortment. There is a wide selection of various textures, ornaments, colors on the market.This makes it possible to select sheets with the most optimal design, corresponding to the general style of the interior interior.

However, despite the mass of positive qualities, the material also has errors.

- Strength. Due to the fact that most of the structure of the material is softwood, it cannot be called durable. Therefore, a rather fragile coating is obtained, which has a low resistance to mechanical stress. To fix this somehow, several layers of wear-resistant varnish are applied to the surface of the material.

- Inhomogeneity. Even when the canvas is made from the same type of wood, its structure and color may vary. In this regard, when purchasing wholesale, it is advisable to order a fine-line from one batch.

At this point, the negative properties of the engineered veneer ended. But to the above, it must be added that fine-line assumes compliance with the established gluing technology and the use of specialized adhesives.

Production technology

The procedure for making an engineered veneer includes a number of key points.

- Longitudinal cutting (peeling) of logs into blades - the log is dissolved into a tape of a certain thickness. The resulting tape is cut into sheets of a certain size.

- Drying veneer sheets and their distribution depending on the color.

- Deep staining - the veneer is dipped into a specialized container filled with dye.

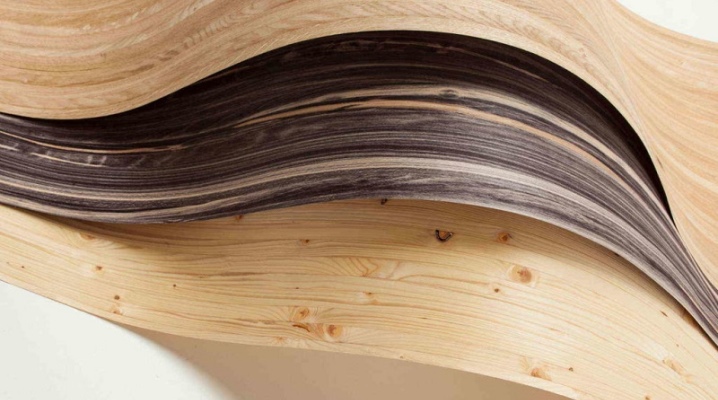

- Gluing. The veneer plates pre-impregnated with paint are stacked and covered with a specialized adhesive with a dye so that the veneer has interlayers of a binder. When gluing, a fairly strong adhesion is formed between the individual veneer plates, and due to the addition of a dye to the adhesive composition, the finished fine-line veneer has a special visual effect.

- Pressing. At this stage, the glued veneer bale is pressed under high pressure.

- Planing. The resulting block is used to make fine-line engineering veneer sheets with a specific pattern and color.

The structure of the veneer produced according to the above method:

- natural wood - 92-94%;

- adhesive composition - 7-8%;

- coloring matter - 0-2%;

- the amount of liquid in the produced material is 8-12%;

- the specific gravity of the material (it all depends on the type) ranges from 450 to 600 kg / m3, the thickness is from 0.35 to 5 millimeters.

Color spectrum

Aesthetics is the main criterion according to which consumers prefer fine-line veneer. This facing material is able to take on the appearance of absolutely any kind of wood, even its most valuable types - no plastic gloss, unnatural colors and the smell of chemistry.

Modern technologies make it possible to paint the veneer in the desired color and apply original patterns on it that convey the texture of natural stone, crocodile skin, fabric, and so on. The surface of the material is extremely smooth, without any irregularities and knots, which are characteristic of natural solid wood and veneer.

How to distinguish from natural?

The reconstructed fine-line veneer has a solid and solid texture. It is made from less valuable softwood, for example, African ayos, poplar. On the natural veneer, the natural pattern is preserved.

This is a more expensive material. It is produced mainly from valuable types of wood, such as oak, maple, walnut, wenge.

Where is it used?

Fine-line veneer is mainly used for the final finishing of various items, including interior doors. In the interior door manufacturing industry, it has received the greatest demand, since it has attractive external characteristics, a variety of colors, textures and an affordable price.

So, during the production of doors, a solid frame of solid wood is created, covered with an MDF board and then the door is faced with fine-line veneer. The advantages of such doors over made entirely of wood:

- practicality;

- less weight;

- stability to temperature changes;

- small price.

Often this material is practiced for the decoration of designer products or in the manufacture of floor coverings. Its use for facing works gives objects an exquisite, noble look. An extraordinary interior with the use of engineered veneer can be obtained by surface veneering.

In the next video, you will see the production process of fine-line veneer from Alpi.

The comment was sent successfully.