Features of Vetonit VH moisture resistant putty

Repair and construction work is rarely done without putty, because before the final finishing of the walls, they must be perfectly aligned. In this case, decorative paint or wallpaper lays down evenly and without flaws. One of the best putties on the market today is Vetonit mortar.

Features and Benefits

Putty is a pasty mixture, thanks to which the walls acquire a perfectly smooth surface. To apply it, use metal or plastic spatulas.

Weber Vetonit VH is a cement-based, super-moisture resistant finishing filler, used for both indoor and outdoor work in dry and wet conditions. Its distinctive feature is that it is suitable for many types of walls, be it brick, concrete, expanded clay blocks, plastered surfaces or aerated concrete surfaces. Vetonit is also suitable for finishing pool bowls.

The benefits of the tool have already been appreciated by many users:

- ease of use;

- the possibility of manual or mechanized application;

- frost resistance;

- ease of applying multiple layers;

- high adhesion, ensuring perfect alignment of any surfaces (walls, facades, ceilings);

- preparation for painting, wallpapering, as well as for facing with ceramic tiles or decorative panels;

- plasticity and good adhesion.

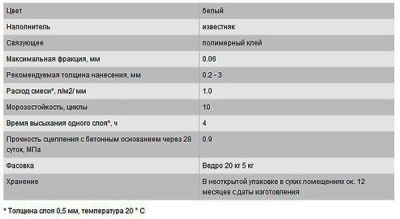

Specifications

When buying, it is worth considering the main characteristics of the product:

- gray or white;

- binding element - cement;

- water consumption - 0.36-0.38 l / kg;

- temperature suitable for application - from + 10 ° C to + 30 ° C;

- maximum fraction - 0.3 mm;

- shelf life in a dry room - 12 months from the date of production;

- drying time of the layer is 48 hours;

- strength gain - 50% during the day;

- packing - three-layer paper packaging 25 kg and 5 kg;

- hardening is achieved by 50% of the final strength within 7 days (at low temperatures the process slows down);

- consumption - 1.2 kg / m2.

Mode of application

The surface must be cleaned before use. If there are large gaps, then they must be repaired or reinforced before applying the putty. Foreign substances such as grease, dust and others must be removed by priming, otherwise the adhesion may weaken.

Remember to protect windows and other surfaces that will not be treated.

Putty paste is prepared by mixing dry mixture and water. For a batch of 25 kg, 10 liters will be needed. After thorough mixing, it is important to let the solution brew for about 10-20 minutes, then you need to mix the composition again using a special nozzle on a drill until a homogeneous thick paste is formed. If you follow all the mixing rules, the putty acquires a consistency that is ideal for work.

The shelf life of the finished solution, the temperature of which should not exceed 10 ° C, is 1.5-2 hours from the moment the dry mixture is mixed with water. When making Vetonit mortar putty, overdose of water must not be allowed. It can lead to deterioration in strength and cracking of the treated surface.

After preparation, the composition is applied to the prepared walls by hand or using special mechanical devices. The latter significantly speed up the process of work, however, the consumption of the solution increases significantly.Vetonit can be sprayed onto wood and porous boards.

After application, the putty is leveled with a metal spatula.

If leveling is carried out in several layers, it is necessary to apply each subsequent layer at an interval of at least 24 hours. Drying time is determined according to layer thickness and temperature.

The range of layer thicknesses varies from 0.2 to 3 mm. Before applying the next coat, make sure that the previous one is dry, otherwise cracks and cracks may form. In this case, do not forget to clean the dried layer of dust and treat it with special sanding paper.

In dry and hot climates, for a better hardening process, it is recommended to moisten the leveled surface with water, for example, using a spray. After the composition has completely dried, you can proceed to the next stage of work. If you level the ceiling, then after applying the putty there is no need for further processing.

After work, all tools used must be rinsed with water. The remaining material must not be discharged into the sewer, otherwise the pipes could be clogged.

Useful Tips

- In the process of work, it is necessary to constantly mix the finished mass with the solution in order to avoid setting the mixture. Additional introduction of water when the putty has begun to harden will not help.

- Vetonit White is intended for preparation both for painting and for wall decoration with tiles. Vetonit Gray is used only under tiles.

- To improve the quality of work, increase the adhesion and resistance of the material, you can replace part of the water (about 10%) when mixing with a dispersion from Vetonit.

- In the process of leveling painted surfaces, it is recommended to use Vetonit glue as an adhesion layer.

- For the surface of the facades, you can paint with cement "Serpo244" or silicate "Serpo303".

- It should be noted that Vetonit VH is not suitable for use on walls painted or plastered with lime mortar, as well as for leveling floors.

Precautionary measures

- The product must be kept out of the reach of children.

- When working, it is important to use rubber gloves, to protect the skin and eyes.

- The manufacturer guarantees the compliance of Vetonit VH with all the requirements of GOST 31357-2007 only if the buyer observes the storage and use conditions.

Reviews

Customers consider Vetonit VH an excellent cement-based filler and recommend it for purchase. Based on the reviews, it is easy to work with. The moisture resistant composition is an excellent option for damp rooms.

The product is suitable for both painting and tiling. After application, you need to wait about a week until it is completely dry. Both professional builders and owners who prefer to make repairs with their own hands are usually satisfied with the process of work and the result.

Thrifty buyers note that it is cheaper to buy a product in bags. Users also recommend remembering to wear gloves when mixing and applying the solution.

See below for tips from the manufacturer of Vetonit VH for leveling the wall.

The comment was sent successfully.