Sanding the walls after putty: the technology of performing repair work

Preparing walls for decoration is a long process that consists of a large number of steps: applying plaster and priming, sanding the walls, re-priming, decorating. Sanding the walls after putty is a necessary process, it allows you to remove small irregularities that are difficult to notice right away. It is necessary to carry out such work, otherwise the wall will not be even. Even the most experienced craftsmen will not get a flat surface immediately after applying the plaster. You should understand the technology for performing the necessary work.

Peculiarities

It may seem to many that such work is not needed, because most often the walls seem to be flat. However, when gluing the wallpaper, so many irregularities will appear that the desire to clean the wall will appear very quickly. It will be very disappointing, because the wallpaper that was recently glued will have to be torn off the surface.

All depressions and bumps, cracks and other flaws will be visible already on the paper web - even if the wallpaper is thick. Even if you work with a spatula as carefully as possible, traces may remain from it, and it will not work to hide them. When painting, all these irregularities will be even more noticeable.

To avoid problems, unnecessary painstaking work, it is better to properly prepare the surface once before further finishing work. For this process, it is necessary to prepare not only the tools, but also yourself - you need to be patient and persistent. Then great work results await you.

Selection of tools

Before carrying out the work, you will need to prepare all the necessary tools.

You will need the following:

- several types of emery cloth;

- rectangular bar;

- sanding mesh;

- sponge for working in hard-to-reach places;

- a set of spatulas;

- spotlight or large lantern;

- ladder, table, sturdy stool;

- individual protection means.

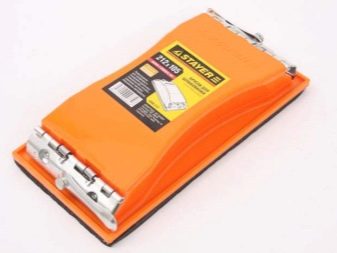

Bar

If you are going to do the job by hand, a sanding block will be needed. The tool itself is simple: a rectangular product with sandpaper or mesh. Sandpaper is a cloth on which an abrasive grain is "scattered". The most important characteristic of sandpaper is grain size.

Sandpaper can be coarse or fine.

Coarse sandpaper is used for the following types of work:

- very rough grinding;

- primary grinding;

- sanding of soft woods;

- finishing of hard wood.

Fine-grained sandpaper is used for the following works:

- finishing of hard wood;

- polishing of final coatings;

- wet sanding;

- metal grinding;

- grinding of plastic products;

- grinding of ceramics;

- fine grinding;

- polishing.

The grain size in fine-grained emery paper is 5-65 microns, in coarse-grained - from 60 to 1100 microns. There are also larger grains, up to 2000 microns, but such products come across very rarely and are used only for very rough processing.

This method of sanding is considered time-tested. When working with large surfaces, you need to stock up on both sandpaper and mesh and patience.

Sander

It is worth paying attention to mechanized devices - grinders. Thanks to them, you can quickly make fairly large surfaces even.Electric cars are heavy in terms of weight but easy to use.

There are three types of machines:

- Belt sander it has significant power, so it is not used for finishing work. Usually it is necessary for sanding the first layer. The abrasive grain belt is guided by special rollers. Centering is carried out automatically - this is why it is convenient. By using special rollers and attachments, you can get close to corners and other hard-to-reach places.

- Orbital eccentric sander are especially popular. With their help, you can not only make the surface even, but even remove old paint. The device has a round platform to which an abrasive material is glued with Velcro. The diameters of the circles are different. The main disadvantage is the inability to work in corners.

- Vibrating flat sander widely used in both grinding and polishing. The abrasive cloth is attached to the machine with special clamps. It is possible to use various attachments (for work in corners and hard-to-reach places).

How to skin: a step-by-step description

Before sanding begins, the surfaces must be inspected. If there are large depressions, then it is better to seal them with putty. Visible large bumps can be removed with a spatula. After carrying out these works, it is necessary to check whether all the putty is dry.

Door openings should be covered with damp pieces of cloth. This is to prevent dust from entering other rooms. Only after that you can start your main work.

Pros advise to start sanding from the top left cornermoving down and to the right. Good results can be achieved through gradual progress. Do not press down on the tool too hard, otherwise new depressions may appear on the wall. A circular motion with the tool will help to grind the surface evenly.

During the entire process, it is necessary to ensure that the skin does not wear off or clog. It needs to be changed (as needed). In order to save money, you can rinse it with cold water, but you cannot use wet skin. Further sanding is possible only when completely dry.

The mesh also needs to be monitored and should be done more carefully. The mesh may bend as it is weaker. Scratching the wall may occur when using the mesh.

To properly sand the corners with your own hands, it is best to use a regular sheet of sandpaper, without a bar. The block may scratch another wall.

It is usually best to sand the wall twice for the best results. First, this is done with coarse sandpaper. For the second grout, use a fine-grained sandpaper.

After all work is carried out, a thorough check follows. Most often, it is carried out with a level, less often with a searchlight. When using a level, it must be applied to all places (to identify bumps or depressions). The spotlight is easier to use: it must be directed to the surface from the side, and all light distortions will show problem areas.

In both cases, either putty or additional work with the sandpaper is necessary. After additional work, it is necessary to check the filled places again - and, if necessary, sand them completely to remove all existing defects.

Only after carrying out all these works will the putty wall be flat. However, all dust must be removed from the surface. The smallest defects can be hidden behind the dust. This is especially important before applying paint or wallpapering. You can use a regular brush or vacuum cleaner.

Helpful hints

There is a wealth of advice from experienced professionals. If you take them into account, the process will run with fewer or no errors.

The following useful recommendations can be highlighted:

- Do not prime the surface before sanding.

- Sanding should be carried out only one day after applying the putty. During this time, the putty should dry, but it will be necessary to check this.

- To check and select the sandpaper that will be needed during work, trial grouting is necessary (it is better to choose inconspicuous places for this).

- A bar or grinder should be carried out in a circular motion.

- You need to work only in good lighting. This will help you see any obvious irregularities.

- If small depressions appear, a small amount of putty can be applied with a rubber trowel. Then it is overwritten. Before carrying out such work, the surface may be slightly damp. You shouldn't be too zealous with water.

Sanding walls is not an extremely difficult job, but it does take time, effort and patience. The utmost care is also required. You can always correct imperfections on the wall so that there are no unnecessary problems when finishing. It is important to remember about the choice of the tool - the result also depends on this. You should rely both on the advice of professionals and on your own experience.

For wall sanding experts' recommendations, see below.

The comment was sent successfully.