Gypsum putty: product features

Putty is the main material for plastering various surfaces and giving them the necessary evenness. Today on the market of repair and finishing materials there is a wide variety of putty mixtures, which are made on the basis of different materials, which determines their field of application and technical characteristics. Plaster putties have proven themselves very well.

Peculiarities

Gypsum putty is made from plaster of paris. This material is obtained after grinding, refining and appropriate processing of hard sedimentary gypsum rocks mined in quarries.

If pure gypsum is diluted in water, then it will quickly begin to harden, similar to alabaster. To increase the hardening time of the gypsum mixture and simplify the process of its application, special substances are added to dry gypsum putties that make the material more elastic and increase its pot life.

In addition to polymer additives, mineral fillers are also added to the putty.such as quartz white sand or marble flour. The particle size of these constituents determines how the finished filler is applied. If, for example, the filler is fine-grained, then with the help of such a mixture a thinner layer of plaster can be applied. As the particle size increases, the thickness of the plaster layer also increases.

It is the quality of the mineral binder that determines the division of all gypsum putties into two types:

- Starting. Designed for plastering the base of surfaces in order to create a base leveling layer, on which a finishing leveling plaster coating will be applied in the future. Such fillers are used for plastering ceilings and walls, leveling small 1-2 cm drops, sealing cracks and other depressions in the bases. Starting compounds are applied to substrates with a thickness of 10-15 mm. To eliminate strong drops, gypsum compositions are not suitable. If you increase the thickness of the layer of such plaster, then it simply will not hold on to the base. In such situations, use other plaster mixtures or resort to leveling the surfaces with plasterboard sheets;

- Finishing. Their main purpose is to form a flat surface for finishing. The finishing putty is applied in one layer, creating a flawlessly smooth and white finish. The finishing type of wall putty is used for further painting, wallpapering, and any other decor. Visually, the finish coat differs from the starting coat in a greater degree of whiteness and smoothness.

In addition to the named types of gypsum mixtures, there are also universal putties, which are used as the only wall treatment material, which is both a preliminary leveling coating and a finishing layer. Such solutions can be applied to various types of bases - concrete, reinforced concrete, brick.

Various plasticizers and modifiers are important components of the gypsum mixture for puttying. Each manufacturer uses different chemical components for this, the formulas of which are the property of the manufacturer and, ultimately, distinguish the various brands of gypsum putty from each other.The presence of these components in the composition determines how quickly it dries and how high-strength the plaster coating will be.

What is the difference?

In addition to plaster putty, other compounds can be used for plastering work. What is the difference between this type of material and other putties, for example, from the so widespread polymer putty?

What these two compounds have in common is that they are designed to perform the same type of repair work - plastering. Both of these products are equally good at filling grooves and cracks, leveling surfaces and preparing them for subsequent decorating.

Gypsum putty has good hygroscopicity, which, on the one hand, makes it a more attractive material in terms of maintaining optimal environmental conditions, but on the other hand, this quality does not make it possible to use it for surface treatment in wet rooms, which is quite within the power of polymer putty. Therefore, if it is necessary to level the walls, for example, in the bathroom, then it is better to use polymer compounds for repair work.

The next difference between gypsum putty is plasticity. This quality is of particular importance if the work is performed by non-professional plasterers. Gypsum compounds are easy to apply and spread well over the surface.

Gypsum putty dries quickly, which allows you to quickly proceed to the next stage of repair work after plastering.

Gypsum putty composition - non-shrinking material, that is, after drying, it does not decrease in volume, which means it does not form cracks, shedding or deflections of the surface. Compared to polymer fillers, gypsum is more environmentally friendly, since it does not contain synthetic components. In addition, gypsum-based materials have a lower price range.

Thus, from the differences of gypsum putty, its advantages follow, distinguishing it from similar building materials:

- Possibility to plaster any bases: brick, concrete, gypsum, plasterboard;

- Environmental friendliness. Gypsum putties do not emit substances harmful to human health into the air and allow maintaining a favorable microclimate in the room due to the fact that in the presence of high humidity, the material will absorb its excess, and when it decreases, it will give moisture back;

- Good adhesion to various types of surfaces;

- No shrinkage, cracks and other deformations of the plaster layer due to the inclusion of special additives that improve its properties in the material;

- Economical material consumption. For comparison - cement putties have a consumption three times more than gypsum ones;

- Easy to apply and sandable. Due to the increased plasticity, gypsum mortars are conveniently applied. Even a beginner in plastering work can cope with filling the walls, you just need to strictly follow the instructions. Surfaces treated with gypsum-based putty lend themselves well to sanding, that is, after drying, you can always correct any surface imperfections using ordinary fine-grained sandpaper;

- Fast drying. This advantage allows you to carry out repair work quickly enough;

- Durability of the created coating. Walls or ceilings plastered with this material can be used for several decades.

The disadvantages of this material include:

- High degree of hygroscopicity, which does not allow the use of the putty in rooms with high air humidity;

- The speed of solidification. A solution for plastering work must be prepared immediately before starting and used immediately, without leaving it next time;

- A short storage period for dry mix, which is usually limited to 6-12 months.

Subtleties of application

Before purchasing the material, it is necessary to decide whether it is possible to putty this surface with a gypsum composition. In principle, this material can be used for processing different types of bases, including OSB-slabs, concrete, brick walls, for filling joints in the laying of tongue-and-groove slabs and in the joints of gypsum boards. But at the same time, it must be remembered that gypsum compositions do not have the property of moisture resistance, which means that they are not suitable for outdoor work and rooms in which there is a high level of humidity. Then it makes sense to use a cement or polymer putty. In addition, plaster should not be applied to stone or ceramic cladding surfaces or chipboard.

Further, depending on the type of repair work performed, it is necessary to determine what type of mixture you need to buy - finishing, universal or starting.

Before starting work with the use of plaster putty, it is necessary to clarify the expiration date on the package. Expired material should not be used. Also, the consumption of the finished mixture should be calculated in advance. It takes about a kilogram of the mixture to create a continuous leveling layer with a thickness of 1 mm and an area of 1 m2. It may take about 30-400 grams per square meter to seal the joints.

Before starting work, properly prepare the base by removing paint or wallpaper from it, and clean it of dirt, grease, chemicals or rust stains. Particular attention should be paid to removing the fungus. For this, special antiseptic agents are used. After that, the surfaces are treated with a primer solution in one or two layers.

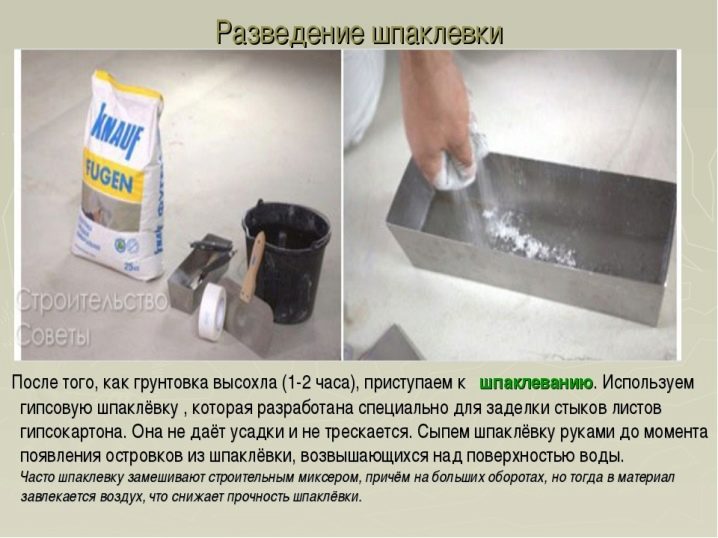

After that, you can start preparing the putty mixture. To do this, the dry mixture in proportion according to the instructions is poured slowly into warm water and distributed gently by hand or with a mixer. Then the mixture should stand for 2-3 minutes and swell. During operation, the mixture must be periodically stirred.

Plastering walls and ceilings with plaster putty is performed with two spatulas of different sizes - one larger, the other smaller. A small one is necessary for applying the ready-made mixture to a large spatula, with which the putty is distributed over the surface. The spatula should be held at an angle (45 degrees) to the surface to be plastered. Slightly tilting the spatula, you should cut off the excess mixture. For distribution of the mixture on the outer and inner corners, special corner spatulas are used.

If the walls have many defects or drops, or you plan to glue thin wallpaper, then the gypsum mixture can be applied in two layers. The surface is smoothed with grout. Each layer of putty must be primed for better adhesion of surfaces. The finishing gypsum composition is applied with a thickness of 1-2 mm. After drying, the surface solution is sanded.

Manufacturers

Today, construction supermarkets offer a wide variety of gypsum-based dry putty mixtures.

Knauf

The line of putties from Knauf, which includes:

- "Uniflot" (for sealing gypsum plasterboard joints);

- "Fugen" (for any interior work, including sealing of seams);

- "Fugen GV" (for filling GVL and GKL);

- "HP Finish" (for any surfaces);

- Rotband Finish (for any reason);

- "Fugen Hydro" (for installation of GWP, grouting of joints between GK and GV sheets, including moisture resistant ones);

- "Satengips" (for any surfaces).

"Prospectors"

- Finishnaya putty is a white plastic material with the use of high quality modified additives for dry rooms with any kind of bases;

- Plaster leveling putty - designed for leveling all types of substrates. The composition includes polymer additives. It can be used for sealing joints between gypsum plasterboards and tongue-and-groove plates.

"Osnovit"

- "Shovsilk T-3" 3 is a high-strength crack-resistant putty. It is used for sealing joints between plasterboard sheets, tongue-and-groove plates, gypsum-fiber sheets, LSU;

- Econcilk PG34G is a non-shrinking universal filler used for leveling various substrates and sealing joints;

- Econcilk PG35 W is a plastic non-shrinking leveling material. It is also used to fill the joints of gypsum fiber board and gypsum board. The mixture has a low consumption;

- Elisilk PG36 W is a finishing material that creates perfectly smooth surfaces for subsequent coating with decorative materials;

Unis

- Finishing putty (highly plastic snow-white) - finishing material with a high degree of whiteness, plasticity and easy to sand;

- “Masterlayer” (non-shrinking thick-layer) is a starting finishing material for sealing shells, cracks, potholes, seams in gypsum fiber board, gypsum board, gypsum plasterboard without the use of reinforcing tape;

- "Blik" (white) - universal, non-shrinking putty, which does not harden within 150 minutes

Pufas

- MT75 is a plaster compound with synthetic resins for smooth subfloors. It is used for filling seams, holes and leveling the surfaces of cement-fiber, GK- and GV-sheets;

- Glätt + Füll - cellulose-added material for creating even subfloors for decorative work;

- Füll + Finish - a finishing compound reinforced with cellulose;

- Pufamur SH45 is a synthetic resin rich putty. Has increased adhesion. Ideal for use on reinforced concrete and other smooth surfaces.

"Gypsopolymer"

- "Standard" - a mixture for continuous basic leveling of plastered, concrete surfaces, GSP, PGP, GVL, treatment of joints between GSP;

- "Universal" - intended for leveling concrete and plastered bases, GSP, PGP, GVL, alignment of joints between GSP, for sealing cracks;

- "Finishgips" is used for joints between GSP, for leveling concrete, plastered bases, bases from GSP, PGP, GVL.

Bolars

- Gips-Elastic is used as a topcoat for various surfaces before painting or wallpapering. It can also be used for filling joints and seams of gypsum-fiber board and gypsum board, installation of GWP;

- "Gypsum" - to create a basic plaster layer on any base;

- Plaster putty "Saten" - finishing material for creating a perfectly smooth and white surface

Bergauf

Bergauf - non-shrinking elastic fillers with improved crack resistance:

- Fugen gips

- Finish Gips.

Gypsum mixes are also produced by Axton, Vetonit, Forman, Hercules-Siberia.

Reviews

In general, this type of putty is very popular among consumers when deciding which material to choose for interior plastering and finishing works.

Consumers note the pleasant boiling white color of the material, versatility (any surfaces can be putty with gypsum compounds), the speed of its drying, which saves time for all repair work, the ability to paint or wallpaper (even thin) walls lined with gypsum-based putties.

Watch a video on the topic.

The comment was sent successfully.