How to choose a finishing putty for painting?

In the process of preparing for the repair, many questions may arise, especially if the work is carried out independently. One of them is the question of choosing a high-quality finishing putty for painting.

Paint is a popular finishing material. It has many advantages over other types of wall decoration, so it is often chosen as a decor. The paint is used in the renovation of offices, warehouses and apartments. This type of finish is durable, not afraid of moisture. The low price also makes painting very attractive.

Before applying paint to the walls, they must be leveled and puttyed.

Therefore, the finishing putty plays an important role during the repair. If the walls have defects, a good putty will help to hide them, and vice versa, a poor-quality mixture will only aggravate the unevenness. Therefore, it is important to choose good material for renovation work.

What is superfinishing putty for?

Finishing putty is an irreplaceable thing in repair. It is the final touch for wall alignment. The material is able to eliminate small flaws. Under the layer of putty, unevenness and roughness are easily hidden. The paint also adheres to walls with putty much smoother than on surfaces without it.

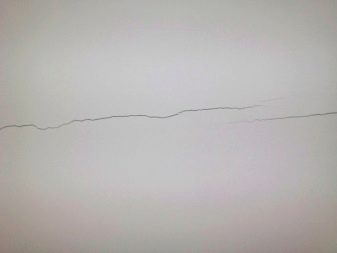

However, do not hope that with the help of putty you will be able to hide gross mistakes. The building mixture is applied in a thin layer, and it can only correct minor flaws.

The putty is usually smooth and uniform in texture. Thanks to this, the composition is easy to use. The white color of the mixture is due to the fact that the shade of the paint can be any (even light). In this case, the putty should not impart any foreign tone to the paint.

Here are some requirements for a putty to look out for:

- Uniformity of structure, absence of lumps and large particles.

- Plasticity, ease of application to walls.

- The material should not dry out and crack after drying.

- The shade should remain white.

Types of putty materials

There are two main types of finishing putty. The mixture can be sold dry or already diluted. If we talk about dry mixes, then they are much cheaper. They also have a long shelf life.

Ready-made building mixture is suitable for those who have little experience in construction and carry out repairs on their own. The cost of such material is higher.

What is included in the putty

Before buying, it is important to carefully study the composition of the material, because the quality of the work and its result depend on it.

The composition of the putty may include the following components:

- Cement. If the material contains cement, it can be used to finish wet rooms and walls of building facades. Cement is a moisture resistant and durable component. However, it also has some disadvantages. One of them is the cracking of the composition after drying.

- Gypsum. Plaster-based putty is often used for interior decoration. However, this mixture also has some peculiarities. The composition dries very quickly. If the mixture is dry, then it is no longer possible to use it.

- Polymers. Polymer putty is excellent for finishing walls before painting. The material does not crack. Special chemicals in the composition of such a putty significantly speed up and facilitate the process of its application to the walls.

Surfaces after finishing with this type of mixture are perfectly smooth. Also, such a putty perfectly masks minor flaws. The disadvantages include only the high cost of this material, although its price is fully justified by the quality.

Where is the best place to apply the finishing putty

If you decide to paint the walls and apply a finishing putty before that, it is worth considering how this room will be operated:

- It is better to finish the walls in the bathroom with putty, which contains cement. This material is not afraid of moisture. This means that after drying, the paint will not peel off.

- It is better to finish the walls in a living room or another room with a plaster or polymer mixture. These options are the safest for humans.

- If you need to create wall decor using putty, you should pay attention to the decorative diluted putty, which contains polymers.

- If the facade is finished, then it is worth using a heat-insulating putty. This mixture retains heat inside the building, preventing cracks and chips from appearing on the surface.

- Also, with the help of finishing putty, you can decorate the ceiling.

What brand of finishing putty to buy

Today the assortment of stores is very wide. Many are faced with the question of which company products to prefer. Professionals, builders with many years of experience can help to understand this. Here are the recommended and most popular companies on the domestic market:

- "Vetonit Lr +". The putty of this brand has proven itself well. It contains polymers and can be the best solution for wall decoration in rooms with low humidity.

- Knauf HP Finish. This brand is known to many Russians. It is notable for its affordable price and high quality. This putty contains gypsum, perfectly hides joints and transitions, and is suitable for decorating living rooms and hallways. Although it is not recommended to use it in the kitchen or bathroom. The material is usually sold in the form of a dry mix. It dries up within 24 hours.

- "Eunice Premium" has established itself as a universal mixture containing polymer particles. This material should be used indoors. It aligns the walls perfectly. In this case, the color remains white, and cracks and scratches do not appear on the surface. This mixture is similar to Sheetrock.

However, it should be remembered that the popular name of the company and the high cost are not indicators of the quality of the material.

When choosing a finishing putty, close attention should be paid to the composition. Also, one of the determining factors when choosing a material should be the type of room for the decoration of which the mixture will be used.

Watch a video on the topic.

How to apply the putty correctly

Before applying any type of finishing putty, the surface should be carefully prepared. Before applying the mortar, it is necessary to apply a primer. This will eliminate the presence of moisture in the base coat. If you skip this step, the likelihood of mold formation will increase several times. The acrylic primer is applied with a roller.

To complete the work, you will need the following tools:

- Putty knife. It is better to use spatulas of different widths.

- Level.

- Plumb line.

- Mixing tools. The ideal option would be a mixer or a drill with an attachment.

- Sandpaper for sanding walls.

- Mixture dilution container

- Separate tray.

Before preparing the solution, carefully read the instructions. Add the required amount of water. Next, stir the mixture well until a homogeneous mass is obtained. A small amount of the mixture is placed in a separate tray. Cover the rest to avoid drying out.

Stir the solution frequently and thoroughly. When the mixture is ready, you can start finishing. It is best to use a narrow trowel for application to walls. With a wide spatula, you can evenly distribute the material around the perimeter of the surface.There can be several layers. The process is laborious and painstaking, but the paint fits well only on perfectly aligned walls.

After the finishing putty is dry, you can safely start sanding. Usually the walls are sanded with sandpaper. This should be done manually. The grit size of the sandpaper should be P220-P280. Do not use paper with a high grain size.

It is better to sand the walls in a circular motion until the perfect smoothness is achieved.

For clarity, you can study the videos available on the Internet. This will help you understand the technology of applying the material and the fineness of grinding.

Professional finishers are more likely than others to work with a finishing putty. They know all the intricacies of the choice and use of material.

Here are some tips from the pros:

- The thickness of the finishing filler should be no more than 2 mm (maximum 3 mm).

- Each new layer of putty must dry completely.

- If light colors are chosen for decoration, then the thickness of the finishing layer should be greater.

- It is possible to process the surface using sandpaper only after it dries out (no earlier than two hours later). The waiting time depends on the composition and the manufacturer's recommendations.

- After the walls are perfectly flat, they must be treated with a primer.

- Before painting, dry and sanded walls are recommended to be viewed in daylight. You can also use any lighting fixture. It is important to make sure everything is done flawlessly. Small cracks, bumps and scratches can be seen through the paint, which can spoil the appearance of the surface.

- Only after all the layers are dry, you can proceed to the final stage - painting the walls.

For information on how to properly sand the walls for painting after putty, see the next video.

The comment was sent successfully.