Subtleties of using the finishing putty Vetonit LR

When a finishing putty is needed, many people prefer Weber products, choosing a mixture labeled Vetonit LR. This finishing material is intended for interior work, namely: for finishing walls and ceilings. However, one putty is not enough for a high-quality coating. The process of its application has a number of nuances that everyone who decides to use this plaster should know.

Peculiarities

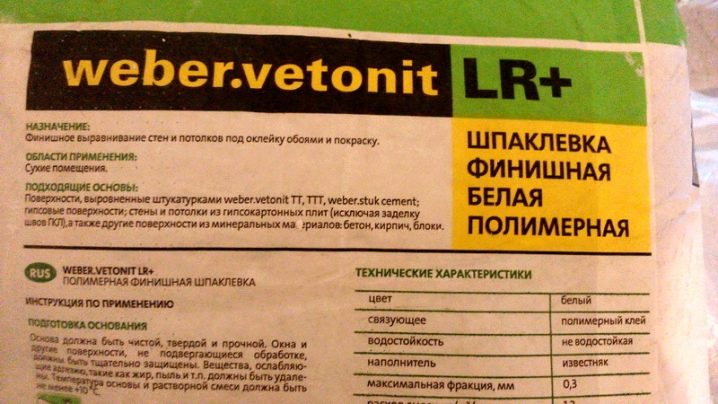

Vetonit LR putty is a product for the final leveling of building envelopes. It is a plaster mixture on a polymer adhesive base, which is intended for finishing dry rooms. It is a powder-type material with a fine fraction and is available in 25 kg bags. The mixture is a semi-finished product, as it needs to be diluted with water before the direct application process. It has a basic white color, which allows you to change the shade of the plaster coating at the request of the customer.

It cannot be used to decorate the facade, since the composition is not designed to withstand moisture and other weather factors. It is the composition that does not allow the use of this mixture on bases that can deform. It cannot be used to decorate wooden houses that shrink during operation. Such a putty is also not applicable in apartment buildings with a high humidity coefficient. In such conditions, it will absorb moisture from the outside, peel off from the base, which will be accompanied by cracks and chips.

Due to its poor resistance to water and fumes, such material can not be used in every room. For example, it is not applicable in a bathroom, kitchen, bathroom, on a glassed-in balcony or loggia. Condensation is the worst enemy of such plaster. Today, the manufacturer is trying to solve this problem by releasing varieties of LR putty. In contrast to them, it consists of polymers, intended for plastered and concrete substrates.

A distinctive feature of the material is the different number of application layers. For example, LR is applied in one layer, therefore, complex multi-layer decorative coatings are not made from it, as this can affect the durability of operation, despite the quality characteristics of the raw materials. She is not equated with large differences: the composition is not designed for this.

The manufacturer recommends using it for the bases:

- cement-lime;

- gypsum;

- cement;

- drywall.

The material fits well not only on a rough, mineral, but also a smooth surface. In this case, the application, in addition to manual, can be mechanized. This will save part of the composition, apply it quickly, which will eliminate the visibility of joints: such a surface will look monolithic. The spraying method involves applying the composition to porous plates.

However, Vetonit LR is not suitable for the floor, which is sometimes done by would-be finishers. You cannot use it as an adhesive for the ceiling plinth: this mixture is not designed for weight load, it is not universal for all the needs of the master. You need to buy it strictly in accordance with the information indicated by the manufacturer on the label. This putty is not a base for the tile, as it will not hold it. In addition, it is not a sealant: it is not purchased for sealing gaps between gypsum boards.

Advantages and disadvantages

As with other plastering materials for finishing floors, Vetonit LR putty has its pros and cons.

- It is created on modern equipment using new technologies, which increases the quality and performance of the material.

- It is easy to use. It is not difficult to apply the material to the floors, the mass does not stick to the trowel and does not fall off the base during work.

- With a small thickness of the applied layer, it trims the base, smoothing out minor irregularities of the starting level.

- Environmental friendliness is inherent in the material. The composition is harmless to health, the coating will not emit toxic substances during operation.

- Fine-grained mixture. Due to this, it is uniform, has a pleasant texture and smoothness of the finished coating.

- In some cases, with sufficient work experience, it does not need to be additionally sanded.

- It is economical. At the same time, due to the powder form, it practically does not form an overrun. Portions can be diluted in portions to eliminate excess mixture.

- The composition has a long life cycle. After preparation, it is suitable for work during the day, which allows the master to complete the finishing without haste.

- The material has noise and heat insulation properties, despite the thin layer of application.

- It is suitable for further finishing surfaces for painting or wallpapering.

- The mixture is available to the buyer. It can be bought at any hardware store, while the cost of finishing putty will not hit the buyer's budget due to its economy.

In addition to the advantages, this material also has disadvantages. For example, Vetonit LR putty must not be re-diluted. From this, it loses its properties, which can negatively affect the quality of work. In addition, it is important to take into account the storage conditions of the dry mix. If it is in a room with high humidity, it will become damp, which will make the composition unsuitable for work.

Vetonit LR is picky about the substrate. The putty will simply not adhere to surfaces that are not properly prepared. On the vastness of the World Wide Web, you can find reviews talking about poor adhesion. However, few online commentators describe preliminary preparation, considering it a useless stage, a waste of time and money. They also ignore the fact that there should be no drafts in the room during work.

In addition, they exceed the application layer, believing that the mixture will withstand everything. As a result, such a coating turns out to be short-lived. A prerequisite that the manufacturer pays attention to is the compliance of the characteristics of the material with the construction work. This mixture does not level the base, it does not mask serious defects, which newcomers in the field of renovation and decoration do not think about.

If the rules of preparation are not followed, difficulties may arise in further work with such a basis. For example, according to the opinions of the masters, when trying to paste wallpaper, the canvas can be partially removed with putty. It is necessary to enhance adhesion, even if the base looks good, and the overlap is made according to all the rules of construction and does not have a porous structure with crumbling. Sometimes an ordinary buyer with a limited budget may not like the price of a large bag (about 600-650 rudders), which forces him to look for cheaper analogs on the market.

Specifications

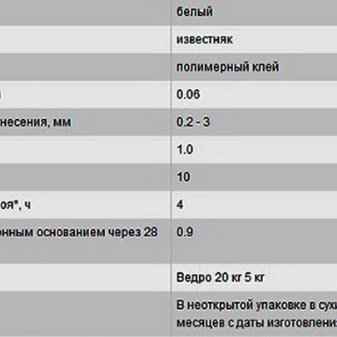

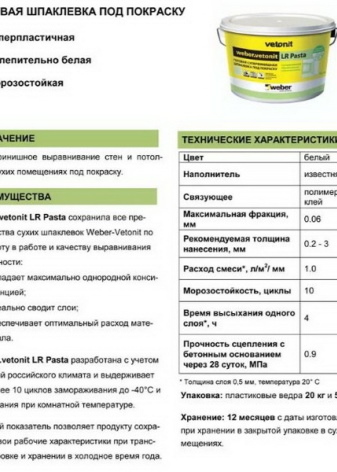

The physical and mechanical characteristics of Vetonit LR putty are as follows:

- moisture resistance - non-moisture resistant;

- filler - white limestone;

- binder - polymer glue;

- vital functions of the finished solution - up to 24 hours after dilution;

- optimal application temperature - from +10 to +30 degrees C;

- drying time - up to 2 days at t +10 degrees, up to 24 hours at t +20 degrees C;

- maximum layer thickness - up to 2 mm;

- fraction of grains in the composition - up to 0.3 mm;

- water consumption - 0.32-0.36 l / kg;

- full load - 28 days;

- adhesion to concrete after 28 days - not less than 0.5 MPa;

- pollution resistance - weak;

- dust formation after grinding - no;

- application - with a wide spatula or by spraying;

- volume of three-layer packaging - 5, 25 kg;

- shelf life - 18 months;

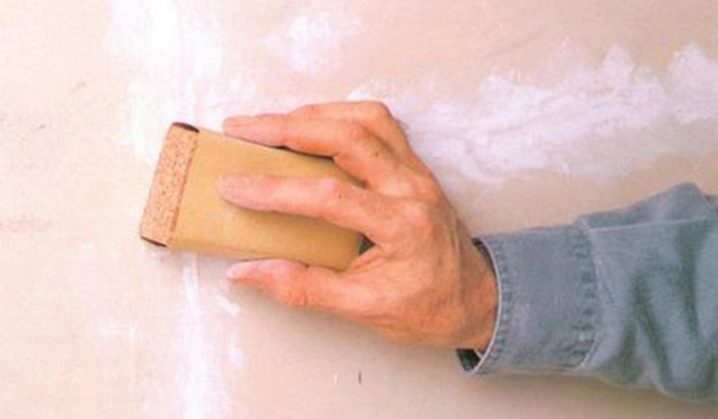

- final processing after drying the layer is not necessary for the ceiling, and sandpaper or sanding paper is used for the walls.

Depending on the variety, the composition may vary slightly, which affects the quality and performance characteristics. According to the manufacturer, the improved modifications are suitable for all types of bases and are particularly durable.

Views

Today the line of Vetonit LR filling materials includes the varieties Plus, KR, Pasta, Silk, Fine. Each modification has its own characteristics and differs from the base material. Materials are divided into two categories: for finishing walls for wallpaper and painting, as well as mixtures for perfect leveling (superfinishes for painting). However, under constant humidity conditions, these coatings can turn yellow over time.

Weber Vetonit LR Plus, Weber Vetonit LR KR and Weber Vetonit LR Fine are polymeric interior fillers. They are superplastic, imply application in a thin layer, are distinguished by simple mixing of layers, which is convenient, since working with such plaster will save time and is suitable even for a beginner in the field of repair and decoration. The materials are easy to sand, are characterized by their pure white color and are a good base for painting. The disadvantage of Weber Vetonit LR Plus is the fact that it cannot be applied to previously painted surfaces.

Analogue Fine cannot be used for wet rooms. Silk is distinguished by the presence of finely ground marble. Weber Vetonit LR Pasta is a ready-to-use finishing polymer filler. It does not need to be adjusted or diluted with water: it is a mixture in the form of a creamy mass, which is used immediately after opening the plastic container. It allows you to obtain a perfectly smooth surface and, according to the manufacturer, has an improved hardness after drying. In other words, it is a crack-resistant, scratch-resistant putty. Its layer thickness can be ultra-thin (0.2 mm).

How to calculate the expense?

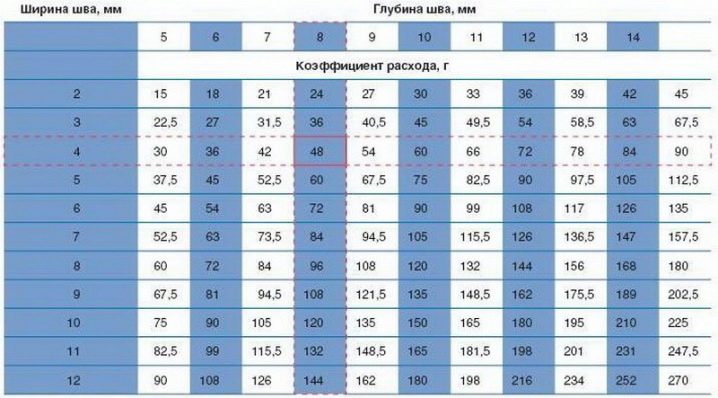

The consumption of material applied to the wall is calculated in kilograms per 1 m2. The manufacturer sets its own consumption rate, which is 1.2 kg / m2. However, in reality, the rate is often at odds with the real expense. Therefore, you have to buy raw materials with a margin, taking into account the formula: norm x facing area. For example, if the wall area is 2.5x4 = 10 sq. m, putties will need a minimum of 1.2x10 = 12 kg.

Since the indicators of the norm are approximate, and in the process of work, a marriage is not excluded, it is worth taking more material. If the putty remains, it's okay: it can be stored dry for up to 12 months. In addition, we must not forget that the application layer is actually larger than the manufacturer's recommended one. This will also affect the overall consumption. Therefore, when buying, it is important to pay attention to the recommended thickness.

Preparation of the solution

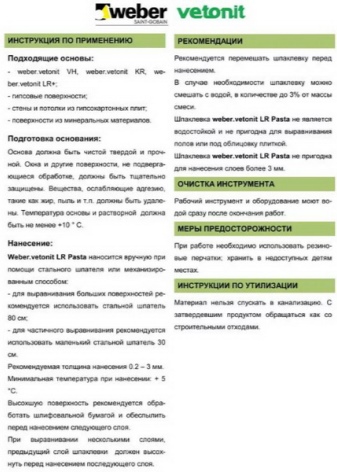

The instructions for preparing the putty are indicated on the package itself.

The manufacturer proposes to breed the material as follows:

- prepare a clean and dry container and a drill with a mixing nozzle;

- about 8-9 liters of clean water at room temperature are poured into the container;

- the bag is opened and poured into a container;

- the composition is stirred with a drill with a nozzle until homogeneous for 2-3 minutes at low speeds;

- the mixture is left for 10 minutes, then re-stirred.

After preparation, the composition will gradually begin to change its properties. Therefore, despite the assurances of manufacturers that it is suitable for days to two with sealed packaging, it is worth using it immediately. Over time, its consistency will change, the mass will become thick, which can complicate the facing of surfaces. The putty dries in different ways, which also depends on the conditions in the room at the time of work.

Application methods

The plaster can be applied manually or mechanically.In the first case, it is collected on a trowel in portions and stretched over the surface, using a rule, as well as a trowel. This option is especially relevant if the customer uses plaster as a decorative coating. In this way, you can mix different shades of the mixture with each other, making the base look like marble. However, their overall thickness should be kept to a minimum.

The second method is convenient in that it allows you to complete the work in a short time. To do this, you can use a sprayer with a large nozzle, some craftsmen manage to apply such a putty with a home-made construction hopper bucket. The bucket is emptied in seconds, and the compound can cover an entire room in a short time. The mass is stretched over the surface by the rule. This method is convenient when a large amount of work is planned.

Analogs

Sometimes an ordinary buyer is interested in how the company’s finishing putty can be replaced so as not to lose in the quality characteristics of the material. Specialists in the field of construction and decoration offer several options for plastering material.

Among them, products of the following brands were highly appreciated:

- Sheetrock;

- Dano;

- Padecot;

- Unis;

- Knauf.

These materials have characteristics that are similar in quality and application. However, experts note that in an attempt to save money, you can lose in quality, because the difference between analog and Vetonit will be small. If you choose a gypsum-based analogue, such plaster will not be moisture resistant. Some experts are sure that if you have the skills, you can work with any finishing plaster. Reviews of builders are contradictory, because each master has his own priorities.

Helpful hints

So that there are no problems in working with the putty, you can take into account the main nuances of preparation and application tricks.

Usually, preparation according to all the rules looks like this:

- the room is freed from furniture;

- carry out a visual inspection of the coating;

- I remove the old coating, grease, oil stains;

- dust from the surface is removed with a semi-dry sponge;

- after drying, the base is treated with a primer.

These are the basic steps for basic material. At this stage, it is important to choose the right primer, since the leveling of the floor structure and the level of adhesion of all layers will depend on it. A primer is needed so that the starting and then the finishing material does not fall off the walls or ceiling. The base is treated with soil with a higher penetrating ability. This will make the structure of the walls uniform.

The primer will bind dust particles and micro-cracks. It is applied with a roller on the main part of the floors and with a flat brush in corners and hard-to-reach places. The application should be uniform, since when the primer dries, a crystal lattice will form on the surface, which enhances adhesion. After the primer has dried, the surface is leveled with starting material. If necessary, it is trimmed after drying and then re-primed. Now for bonding the starting and finishing layers.

After the primer is completely dry, the filler can be applied. The application of the primer is not a useless procedure or an advertising stunt for sellers. It will allow you to exclude chipping of the putty, if you have to, for example, adjust the wallpaper when gluing. The type of tool used is important in the process of finishing the planes.

For example, to prevent the putty from sticking to the trowel, you should not use a wooden spatula. It will absorb moisture, and with it, the mixture itself will be retained on the working canvas. If the area of the room is small, you can try a 30 cm wide metal spatula or a two-handed tool. The mixture should not be applied to damp floors. You need to dry the wall (ceiling).

Antiseptic treatment is also important. For example, in order to exclude the formation of mold and mildew on the surface of the wall or ceiling being trimmed, the floors can be initially treated with a special compound.In addition, in the process of work, it is important to observe the temperature conditions in the room. If the plaster mix is applied in several layers, it is important that their thickness is minimal.

If the surface is being polished, you need to wipe off the dust every time, which is easier to do with a semi-dry sponge. It will not scratch the finished surface. When applying each new layer, it is important to wait until the previous one is completely dry. The ironer is also used in the case of decorative application, and even relief. In this case, the pressure on the tool should be minimal.

Watch a video on the topic.

The comment was sent successfully.