All about putty for OSB boards

The preparation of OSB boards for subsequent cladding has a number of nuances, and last but not least, it is puttying. The general appearance of the finish and the stability of the outer layers largely depend on the quality of this work. Let us dwell in more detail on which putty compositions are used for interior and exterior work on OSB.

Species overview

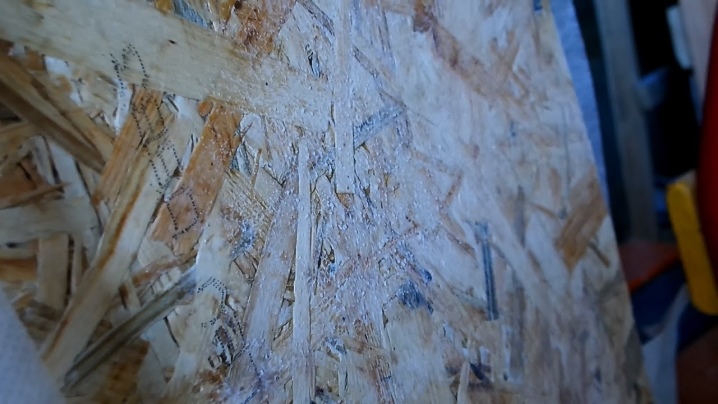

OSB is a multi-layer board made from wood-fiber shavings pressed and glued with synthetic resin under the action of heat and increased pressure. All layers have different orientations, due to which the board acquires exceptional resistance to deformation.

This is a fairly common finishing material. However, working with it requires certain skills and knowledge. Despite the high percentage of synthetic substances, 85-90% of such panels are composed of wood-fiber components.

That is why they have many of the characteristics of natural wood, including the ability to absorb water.

This feature raises great doubts that such a panel can be putty. It is possible, puttying of OSB sheets is allowed. At the same time, the technology for performing work inside the heated room and outside is practically the same.

Puttying allows you to achieve the following results:

- protection of the wood-fiber structure of the panel from atmospheric influences - precipitation, vapors and direct UV rays;

- protection of OSB sheets from aggressive components, which are present in large quantities in facing materials;

- preventing the appearance of gummy discharge on the finish veneer;

- masking joints, cracks and other installation flaws;

- formation of a leveled monolithic layer with high adhesion;

- getting the illusion of a concrete surface, hiding the wood texture;

- additional protection of premises from volatile formaldehyde compounds.

For finishing OSB boards, different types of putty are used.

Oil and glue

The main components of oil glue putties are:

- drying oil;

- adhesive composition;

- plasticizer;

- thickeners;

- fungicides;

- water.

It is used in warm rooms for wallpapering, as well as for subsequent painting. It is not applied under plaster. Does not mask defects larger than 0.5 cm.

Pros:

- economical consumption;

- affordable cost;

- no release of volatile toxins;

- distribution over the surface in a thin layer;

- the possibility of manual grinding;

- ease of use.

Minuses:

- can be used exclusively at temperatures over 15 degrees;

- does not withstand strong temperature changes;

- putty coatings do not withstand moisture and are quickly damaged by mechanical stress.

Polymer

This putty based on acrylic or latex can be used for finishing all rooms, including bathrooms, swimming pools, kitchens, as well as unheated country houses. It is allowed to use acrylic putty outdoors when finishing facades. It goes well with any subsequent finishing options.

Pros:

- forms an ultra-thin snow-white coating;

- has good sound insulation;

- resistant to fungi;

- moisture resistant;

- vapor permeable;

- tolerates heat and temperature fluctuations;

- durable;

- plastic;

- without smell;

- durable.

Minuses:

- latex resins can only be applied in a very thin layer;

- the putty dries quickly, therefore it requires the fastest possible application - in the absence of work skills, this can lead to the appearance of defects and the need to rework the entire work.

And, finally, the main drawback of latex putties is the high price.

Other

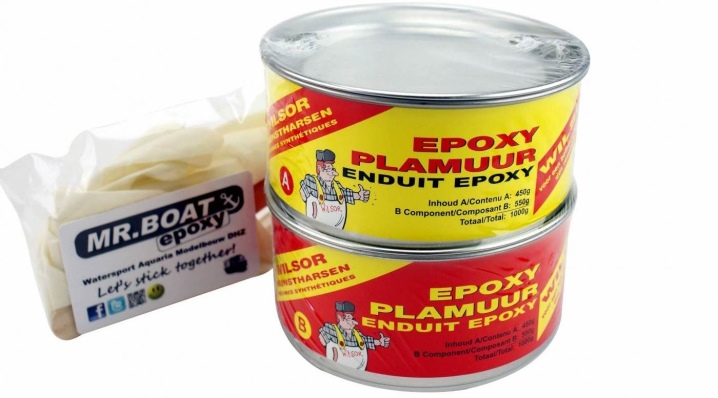

There are several other types of putties that can be adhered to wood - these are alkyd (nitro putty) and epoxy. The coating formed by these compounds is characterized by strength and long service life.

At the same time, they have a number of disadvantages. So, alkyd mixture is quite expensive and extremely toxic - it is more often used for repairing vehicles. Epoxy - forms a tough but vapor-proof coating with low adhesion to the finish. In addition, like nitro putty, it has a high price.

It is more often used for the restoration of small areas on the surface, but it is unsuitable for serious repair and finishing work.

Popular brands

SOPPKA. This putty is used to correct defects and fill irregularities of OSB boards, as well as fiberboard, chipboard and plywood. It is applied before finishing in wet or dry rooms. The surface of the putty is well sanded, it can be pasted over with acrylic or vinyl wallpaper, as well as painted.

Fungicidal additives are introduced into the composition of the material, which protect the fibers of the panels from all types of fungus and mold.

The advantages of the putty include:

- ease of application;

- resistance to cracking;

- high adhesion;

- environmental safety;

- lack of a sharp chemical odor.

NEOMID. It is a water-based polymer putty. Used for work in dry and damp houses. When applied, they form an elastic, moisture-resistant coating. Does not crack. Gives the surface strength and durability. After drying, it can be sanded, as well as subsequent wallpapering and painting.

Semin Sem. Another water-based putty for OSB sheets. It is used in dry and damp rooms, for cladding the surface of walls, ceilings, as well as seams. It has elasticity, moisture resistance and resistance to cracking. Differs in high adhesion, therefore, when used in interior decoration, it is not necessary to prime the surface. For exterior finishing, it can be used in conjunction with facade primer. It can be sanded well by hand.

Can be further dyed or wallpapered.

Nuances of choice

Regardless of what components are the basis for the production of putty, it must have a number of characteristics.

- High adhesion. Any boards made of oriented strand materials are usually coated with resins or wax. Therefore, not every putty can firmly adhere to such a surface.

- Homogeneous consistency. The putty composition should not include large-sized particles - this can significantly complicate the performance of finishing and facing work.

- Low shrinkage. This property minimizes the risk of cracking as the filler dries. Thus, the quality of work increases and the time for their implementation is reduced.

- Hardness. Putty mixtures used for such a complex material as OSB boards should be as hard as possible, but at the same time it is good to be sanded, including by hand.

- Possibility of subsequent finishing. The putty is used as an intermediate stage of facing. Therefore, the dried, sanded surface of the material must be suitable for various types of further cladding, be it painting or wallpapering.

When buying a putty, it is very important to choose the right putty composition, since the quality of the repair performed and its duration largely depends on it. Most of the failures in the work are associated with the miscalculations of unskilled craftsmen who performed the putty.

So, cement and gypsum building mixtures are not suitable for working on OSB. Of course, they are cheap, differ in density, mix well and distribute without problems on the plate. But their main drawback is the lack of elasticity. The tree periodically changes its volume depending on the temperature and humidity parameters in the room, so both the starting and finishing putty will lag behind it.

Due to the popularity of OSB boards in repair and decoration, a large selection of putty compounds from different manufacturers has appeared in the construction segment. Of all the variety, you need to choose the most elastic solutions that are optimal for working with wood-based materials.

It is better to give preference to ready-made compositions in cans or plastic buckets. Their use will protect against mixing errors of the active composition. In addition, it will allow you to take your time when distributing the solution for fear that the freshly diluted mixture will dry out quickly. The only drawback of such a solution is the high cost, such a putty will cost much more than dry packaged formulations.

It should be noted that the definition of "putty" is often used in the names of mixtures. In theory, both "putty" and "putty" mean the same thing. These words came into use at different times, but today both terms are allowed to be used.

Application features

When all the working material is selected and purchased, you can proceed directly to puttying. There is not much difference in how to putty the panels under paint or under wallpaper - the sequence of actions will be the same in any case.

- The first stage involves the application of a high adhesive primer. This solution creates a film on the surface of the material, it prevents the appearance of resinous stains, essential oils and other components present in the wood.

- Then you need to take a short break for the final drying of the surface. Its duration directly depends on the type of primer and averages 5-10 hours.

- The next stage is the direct application of the putty. We draw attention to the fact that this work can be performed exclusively at positive temperature values of the air, at a humidity level not exceeding 60%.

- After applying the putty, you should arrange another technological break for its final drying.

- At the third stage, the surface is sanded to make it smooth, even and eliminate all defects. If necessary, reinforcement with a metal mesh is performed.

It's obvious that puttying OSB panels is a simple job and you can cope with it yourself. Nevertheless, theoretical knowledge alone is not enough to putty such a capricious material. Therefore, in the absence of skills in working with wooden surfaces and building mixtures, it is better to turn to professional craftsmen.

In our review, we tried to answer as fully as possible the question of which finishing materials are best used for puttying OSB panels, how to finish. In conclusion, we note that there is no need to putty at all, if you are not going to mask the structure of the wood material. But for gluing wallpaper, as well as for painting, such a finish is necessary - it will protect the base from moisture and allow you to form a durable decorative coating.

The comment was sent successfully.