Grinding machines Makita: features, models and rules of operation

Modern Makita sanders are widely represented in the market for hand-held pneumatic, cordless and corded power tools. The Japanese brand produces both professional and household equipment, provides timely updates to the product range.

Peculiarities

Without knowing the features of belt and eccentric sanders, it is difficult to make the right choice of technology. Equipment performance and performance are critical to successful operation. Before choosing pneumatic and vibration machines for working on wood and concrete, metal and stone, you should carefully study their capabilities, operational requirements. It is important to remember that ordinary household models are not designed for continuous continuous operation. If you have to use the grinder regularly and for a long time, you should choose the version for professional use.

The Makita sander is designed for the processing of hard surfaces.

The equipment performs polishing, grinding of metal, plastic, wood, concrete, stone, allows you to achieve the desired level of smoothness, remove the old coating, prepare the material for decorative coating. The working part of the equipment is a disk or tape-type plate that rotates at a certain frequency.

All variants of grinders presented in the model range of Makita equipment are divided into the following types:

- corner;

- vibrating;

- flat (deltoid, tape, eccentric);

- brush.

Surface grinding techniques are considered the most popular. This type of power tool adheres to the working surface completely, with the entire rotating platform. Eccentric models are equipped with disc nozzles. Deltoids are similar to irons, are made in a compact size range, and are used in the treatment of difficult, hard-to-reach areas. Small area triangular sole is comfortable and functional, suitable for home workshop use.

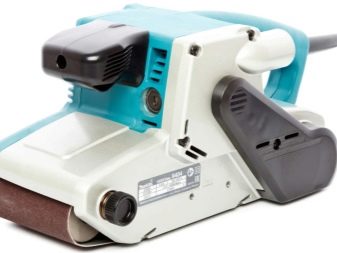

Makita belt sanders are equipped with a rectangular platform.

The belt is stretched over two rollers and moves along a straight path. This approach provides opportunities for successful processing of a large surface area, the platform itself can also be large. Belt sander machines are used for scraping parquet and maintaining wood floors. A grinder or grinder, in addition to direct grinding, can be used in conjunction with cutting wheels to perform a wide range of operations. As a rule, it is used for mechanical processing of surfaces located in a vertical plane.

Such models are convenient for manual use, available in battery and wired form.

Vibration models of Makita grinders deserve special attention. They use grinding mechanisms that generate vibration vibrations with a low amplitude. The frequency of movements reaches 20,000 per minute. Machines of this type are considered industrial or professional because their performance allows them to quickly process a large area of coverage. Woodworking has its own subtleties.Coarse grinding is convenient to carry out using brush machines with a cylindrical working platform. For grinding on metal, such a tool is not used due to the too low intensity of the impact.

Advantages and disadvantages

Reliable Japanese Makita equipment is distinguished by such a set of obvious advantages as:

- wide price and model range - you can choose equipment for any budget and task;

- light weight and compact dimensions - only professional models are large-sized, hand tools are easy to use and store;

- reliable components make it possible to ensure the longest possible operation of the equipment without damage or replacement;

- the presence of dust collectors in the kit - it is possible to ensure the collection of the generated waste during the grinding process;

- adjustable position of the handles - you can hold the unit with convenience, choose a comfortable way of fixing the tool in the palm of your hand;

- the choice of networked and autonomous models of equipment with a battery.

Not without flaws. Among them, consumers note the small length of the cord in some models of hand tools. Newer models of equipment may have problems with the lapping of the switch. At first, its course can hardly be called smooth. The lack of speed control in a number of models can also be called a disadvantage that does not significantly affect the functioning of the equipment.

Models and their characteristics

The range of grinders produced by the Makita brand is quite diverse and allows you to purchase a full range of equipment for your home workshop, metalworking, woodworking from a single source. Among the most popular and relevant equipment options, several varieties can be distinguished.

- LBM. The range of Makita grinders is very diverse. The price range ranges from budget to professional. The most popular options are GA7010C and GA5034. There are rechargeable models.

- Tape for wood, metal. Among the models of the current range of products, it is worth highlighting options for compact files that work on the same principle - they are not cheap, have high power, differ from full-size options only in ultra-compact dimensions. The budget options are considered to be the options of grinders with numerical indices 9910 and 9911. The professional version is the Makita 9920 with a power of 650 W, with an adjustable speed, belt speed up to 270 m / min, a built-in dust removal and collection system, graphite plates and plugs included.

- The electric eccentric sander is available in a wide range of models. Household options - BO5020, BO5040 have low power, suitable for performing the most simple operations. For more intensive use, it is recommended to choose the BO6050J model with a large abrasive wheel diameter, 750 W power, modern electronic equipment.

- Rechargeable. In this category, eccentric versions of the BBO140Z with a 3.0 A * h battery and DBO180RFE are presented, quite resourceful - the idle speed reaches 11,000 rpm. And also in the manufacturer's catalog you can find non-volatile straight grinders - budget Makita BGD801Z, full-function BGD800RFE, developing speeds up to 25,000 rpm.

- Straight - used for processing small areas. The nozzle is located in the form of a tip of the working area, the range is represented by the household options GD0602 and GD0603, professional models GS6000 and GS5000. There are also pneumatic models that run on compressed air.

- On concrete. Makita distinguishes its models of this class PC5001C, PC1100 in a separate category. Professional equipment has a power of up to 1400 W, a stroke frequency of 10,000 rpm, equipped with diamond cups and electronic control systems.

- Brush. In the current model range, there is only a professional Makita 9741 unit.The 860 W version can work on metal, provide high-quality structuring of wood fibers. Quick-change attachments and precise positioning make the equipment convenient for work in the home workshop.

- Vibrating. The most budgetary versions - BO4561, BO4563, BO3700, which have low power, up to 200 W, compact size and minimum weight. For more serious work, it is better to choose the BO4900V version with a power of 330 W and an idle speed of 4000-10,000 rpm.

Important! When buying a grinder, it is worth considering the status of the grinder model, its purpose, design features, operating conditions.

Selection Tips

Many people are interested in the question of how to choose the right model of the Makita grinder. First of all, you need to decide on its purpose. If the technique is planned to be used in a home workshop, a multifunctional orbital (eccentric) model, convenient for use on a workbench, is suitable. For professional use in floor scraping, repair and finishing, it is better to use a vibration or straight type tool - it is more productive, designed for intense loads. A grinder with a cutting function is a convenient solution if you plan to use it for general household purposes. Here it is worth considering the options for purchasing cordless or network angle grinders that allow you to change the cutting and grinding options for the equipment.

For working with concrete and stone, you should immediately purchase modern professional models of the tool that have the highest productivity, intensity of impact on the surface of the material.

When choosing equipment, it is imperative to take into account the presence of a dust collector - this useful option will greatly facilitate the process of cleaning the workshop in the future. Another important point is the tightness of the case. It should be as high as possible so that when heated, there is no risk of ignition of wood or plastic dust.

How to apply?

Makita Grinder Process requires careful adherence to the following manufacturer's recommendations:

- the main precautions are related to the observance of electrical safety standards - do not handle the wires and plug with wet or damp hands, it is recommended to use protective glasses and gloves, rubber-soled shoes during work;

- when choosing grinding equipment, you need to take into account the standard width of the belt and the diameter of the disc;

- a preliminary check of the equipment is required before work; the presence of mechanical damage in the structure of the case, wiring, rotating element excludes the use of equipment;

- when starting, it is imperative to investigate the balancing of the disc, because it is needed to exclude knocking and vibration when the grinding element rotates;

- during work, direct contact of hands or other parts of the body with the rotating parts of the tool is prohibited; a respirator is required to protect the face, a working ventilation system in the room;

- the power tool excludes the possibility of abrasive effects on wet surfaces.

Modern Makita grinders offer a variety of designs and ways to rotate the abrasive mechanism. They are chosen by amateurs and professionals, they are noted at specialized exhibitions as an example of a reliable power tool that can maintain its performance for a long time.

For an overview of the Makita belt sander, see the video below.

The comment was sent successfully.